Clamping Mechanism for Precision Small Modulus Gears

A small-module gear and clamping mechanism technology, which is applied to gear cutting machines, components with teeth, gear tooth manufacturing devices, etc., can solve the problems of small-module gear wear and tear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

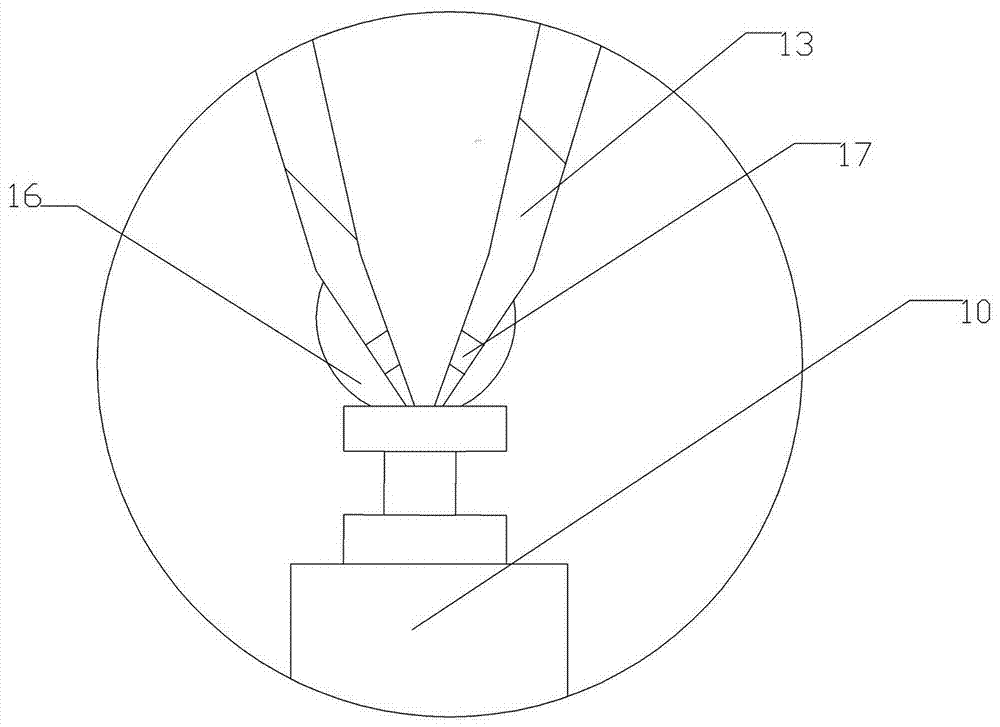

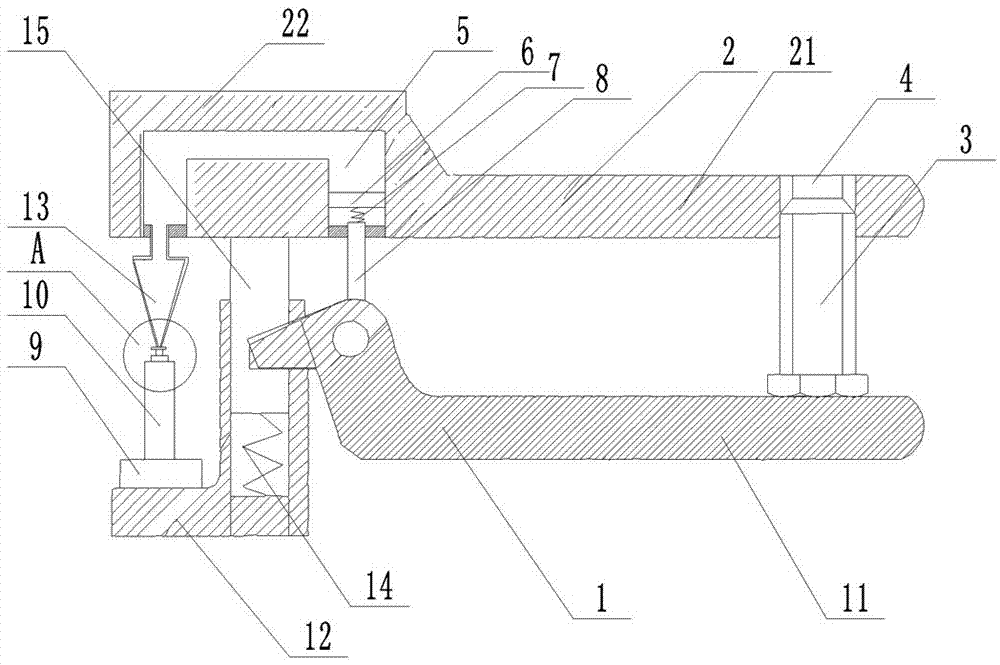

[0019] Basic as attached figure 1 As shown: the clamping mechanism of the precision small modulus gear 10 in this solution includes the fixed arm 1 below and the movable arm 2 above. The fixed arm 1 includes a clamping part 12 and a hand-held part 11. The clamping part 12 The left side is connected with a support seat 9 through a bearing, and a groove is provided on the support seat 9, and a small modulus gear 10 is placed in the groove, and a round hole is opened on the right side of the clamping part 12, and a first spring 14 is welded at the bottom of the round hole. The top of the first spring 14 is welded with a sliding shaft 15, the top of the sliding shaft 15 is in contact with the short arm 22 of the movable arm 2, the sliding shaft 15 is hinged with the integrally formed protrusion at the left end of the handle 11, and the right end of the handle 11 is rotatably connected with a fine-tuning screw 3. The fine-tuning screw 3 is screwed into the threaded hole 4 of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com