Robot handheld force control belt sander

A kind of abrasive belt machine and hand-held technology, which is applied in the direction of abrasive belt grinder, grinding machine parts, workpiece feed motion control, etc. Grab the workpiece grinding operation and other problems, achieve the effect of controllable grinding accuracy and consistency, strong promotion and application value, grinding accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

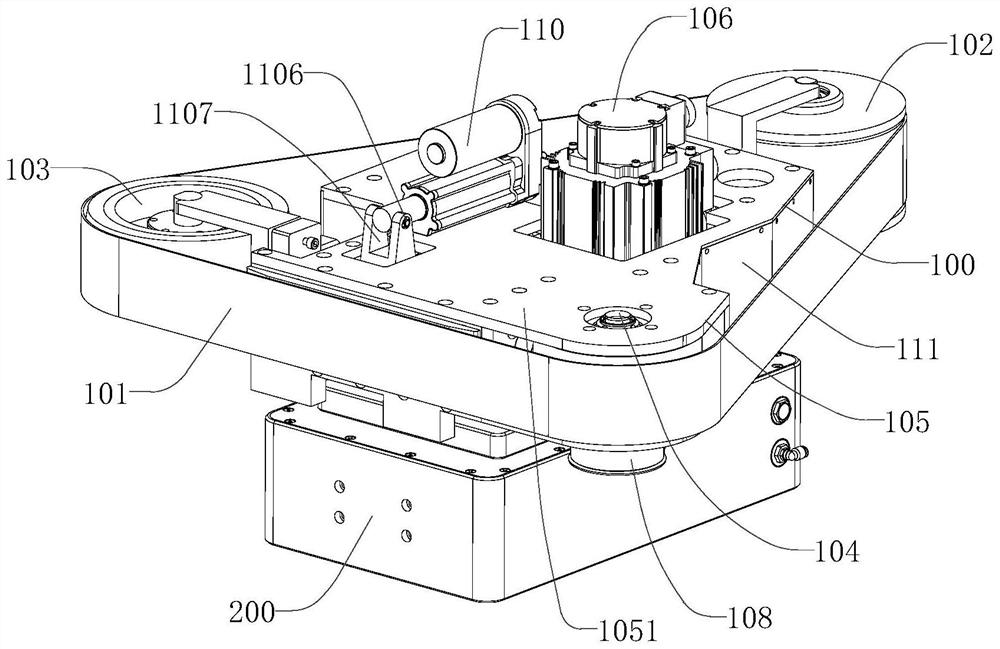

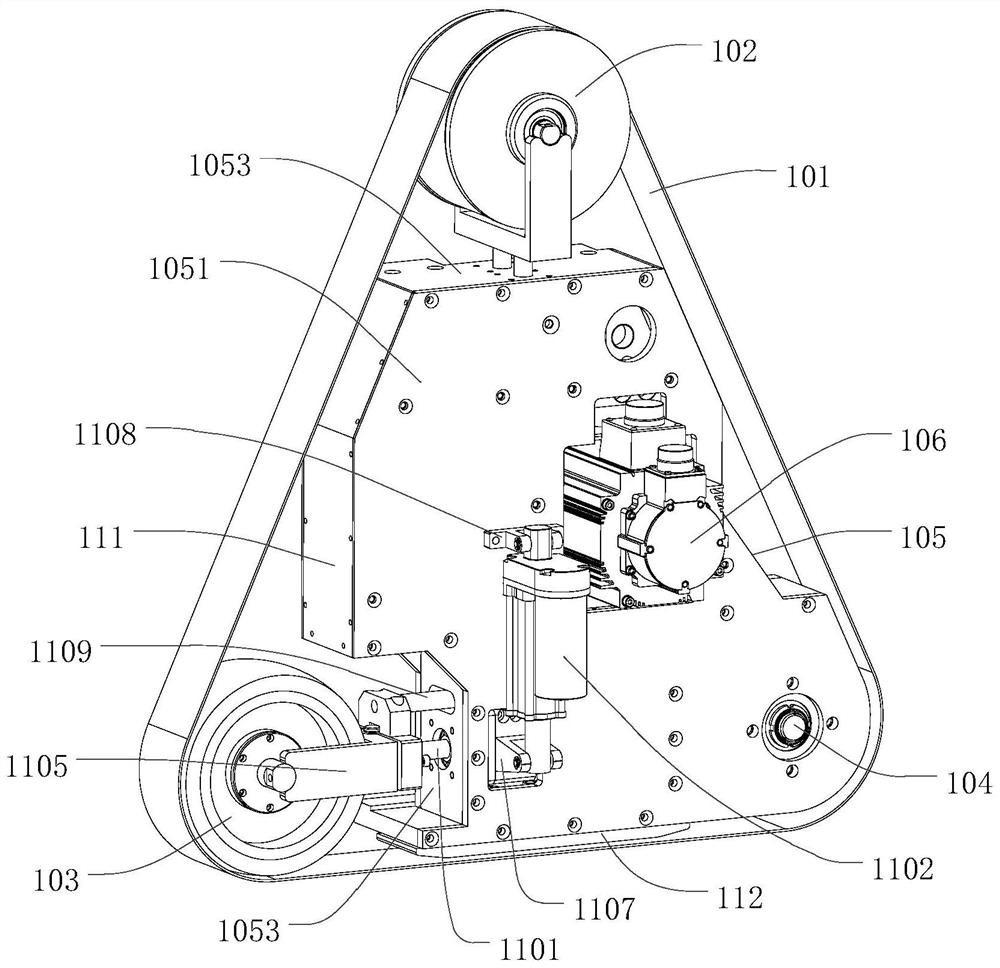

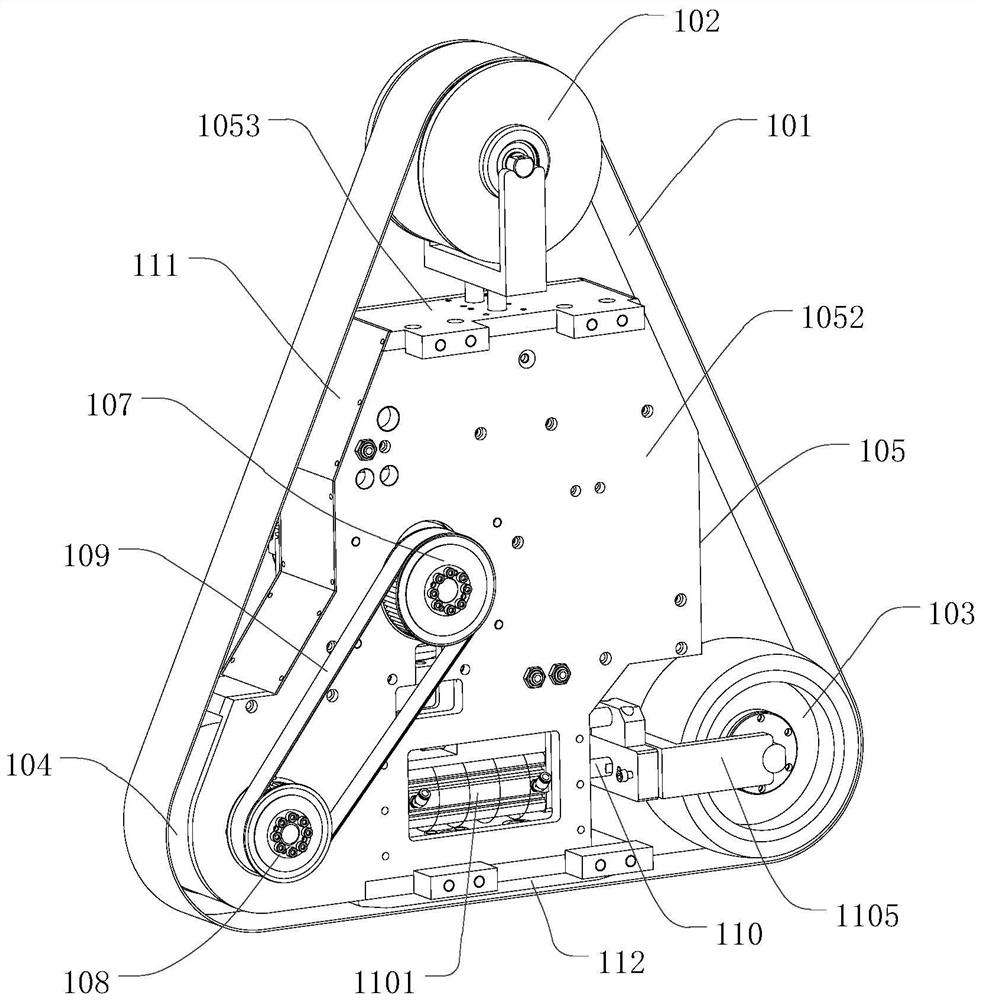

[0036] like figure 1 , figure 2 , image 3 , Figure 4 Shown: a robot hand-held force-controlled belt machine, including a belt machine body 100, the belt machine body 100 includes an abrasive belt 101, a grinding wheel 102, a tensioning wheel 103, an abrasive belt driving wheel 104, an installation base Seat 105, the abrasive belt 101 is wound around the outside of the grinding wheel 102, the tensioner 103, and the abrasive belt driving wheel 104, and the installation base 105 includes a front base plate 1051, a rear base plate 1052, and a connecting plate 1053. The connecting plate 1053 is connected to the front 1051 and the rear base plate 1052, and the connecting plate 1053 at one end of the grinding wheel 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com