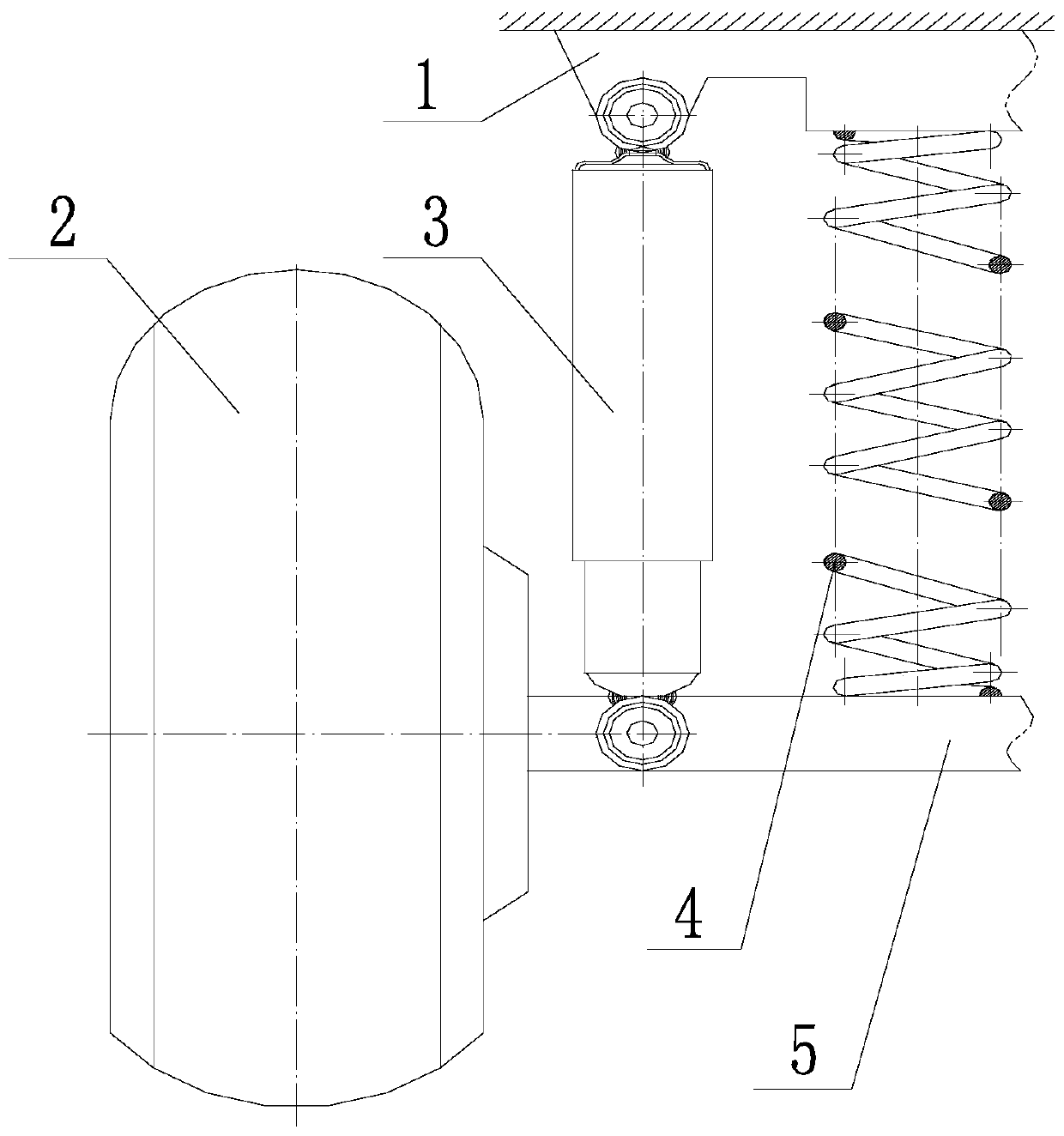

Projection welding method for piston rod and connecting ring of automobile shock absorber

A welding method and piston rod technology, applied in welding equipment, vehicle parts, resistance welding equipment, etc., can solve problems such as hidden dangers of piston rod quality, failure of sealing effect, oil leakage, failure of shock absorbers, etc. Improve product quality and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

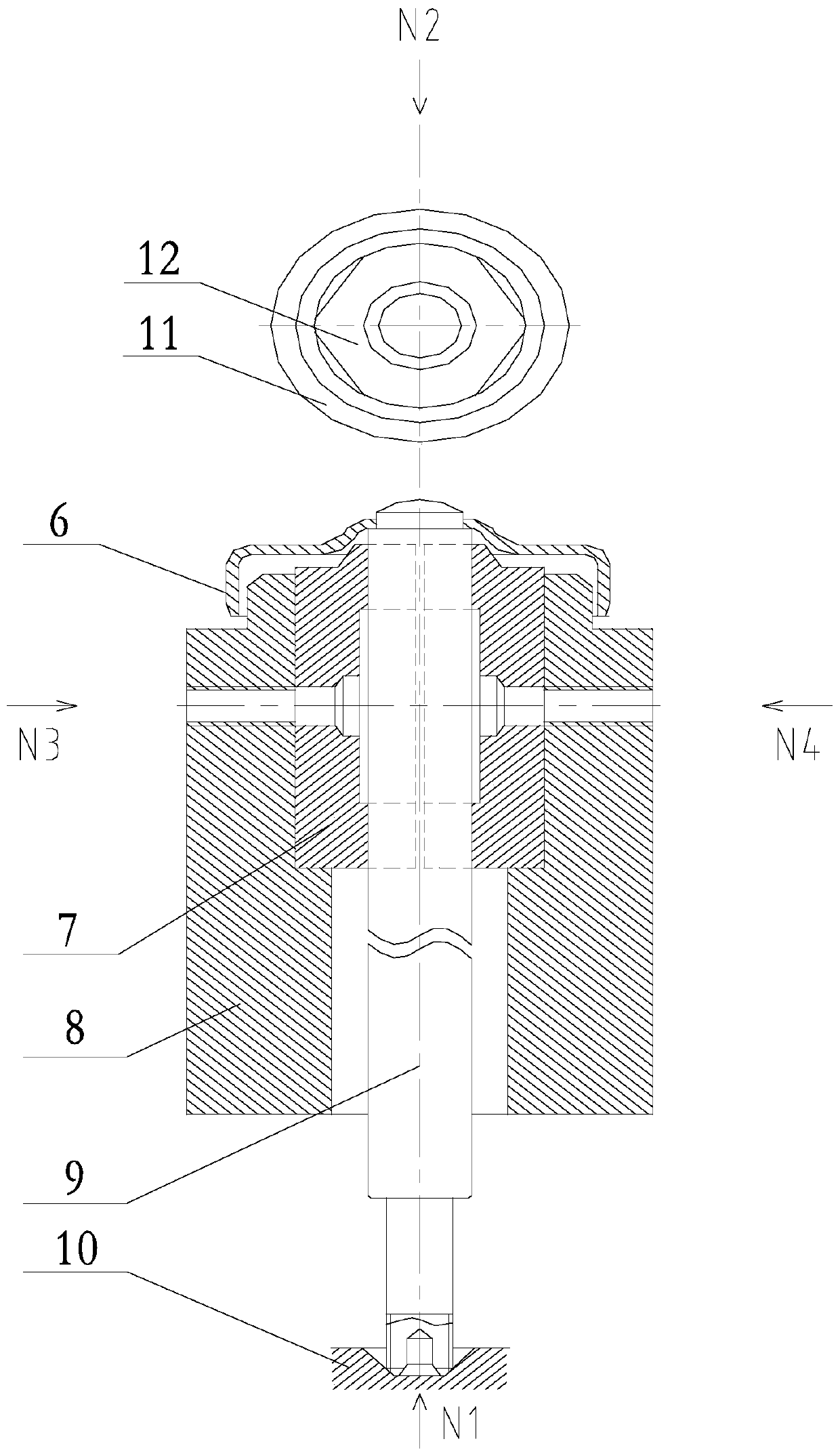

[0037] Such as Figure 5-6 As shown, this embodiment includes the following steps:

[0038] A. Fix the dust cover 6 on the upper end of the piston rod 9, then;

[0039] B, fixing the connecting ring 11 on the positioning electrode 12;

[0040] C. Send the piston rod 9 into the welding position and fix it;

[0041] D Utilize at least two clamping electrodes 13 to clamp the outer peripheral wall of the dustproof cover 6, and push the positioning electrodes 12 to move down until the lower part of the connecting ring 11 contacts the upper end of the piston rod 9;

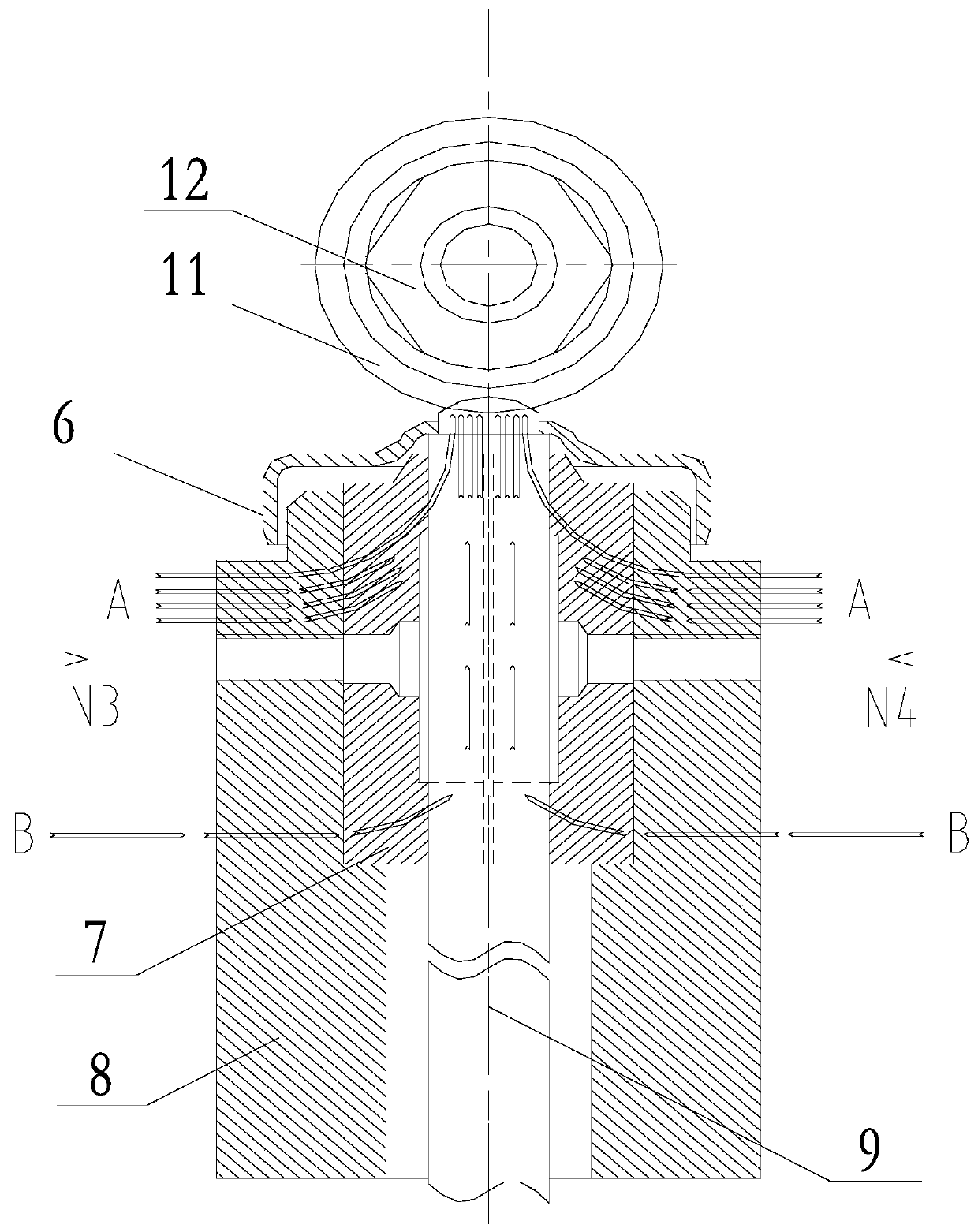

[0042] E. After the connecting ring 11 contacts with the upper end of the piston rod 9, a welding circuit is formed to weld the piston rod 9 and the connecting ring 11. In the existing projection welding process, by applying forces N3 and N4 to the side walls of the two clamping electrodes 7, the piston rod 9 is stably clamped and fixed, and the electrode holder 8, the electrode 7 and the piston rod 9 together form a...

Embodiment 2

[0046] Such as Figure 5 with Image 6 As shown, the piston rod 9 includes a main body and a thin neck section connected to the upper end of the main body, and the outer diameter of the thin neck section is smaller than the outer diameter of the main body, and the dustproof cover 6 is arranged on the thin neck paragraph. Piston rod 9 is divided into two parts, namely main body and thin neck section, and the outer diameter of thin neck section is less than the outer diameter of main body, and dustproof cover 6 is fixed on the thin neck section, utilizes the outer diameter between thin neck section and main body The diameter difference ensures that the contact is sufficiently conductive and prevents the clamping electrode 13 from loosening between the dust cover 6 and the thin neck section when the clamping electrode 13 clamps the dust cover 6, thereby improving the quality of projection welding.

[0047] Further, there is an interference fit between the dust cover 6 and the t...

Embodiment 3

[0050] Such as Figure 7As shown, a flange 15 coaxial with the inner hole of the dustproof cover 6 is arranged on the top of the dustproof cover 6 , and the inner diameter of the flange 15 is the same as the inner diameter of the inner hole of the dustproof cover 6 . A flange 15 is provided on the dustproof cover 6, thereby increasing the contact area between the dustproof cover 6 and the interference fit area of the thin neck section. The gradually increasing projection welding fusion area between the rings, after the welding circuit is formed, quickly generates a large amount of resistance heat at the place with the largest resistance in the circuit, so that the bottom of the connecting ring 11, the top of the dustproof cover 6 and the thin neck section The ends reach the temperature range where they can be fused together, and under the extrusion action of the pressure generated by the downward movement of the positioning electrode 12, the melting metal grains on the conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap