A Linked Swing Head Device with Height Difference Compensation and Its Parameter Determination Method

A technology of height difference and linkage, applied in the direction of transmission, drive, friction transmission, etc., can solve the problems of increasing cost and increasing the complexity of control system, and achieve the effect of reducing height error, reducing cost and simplifying control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

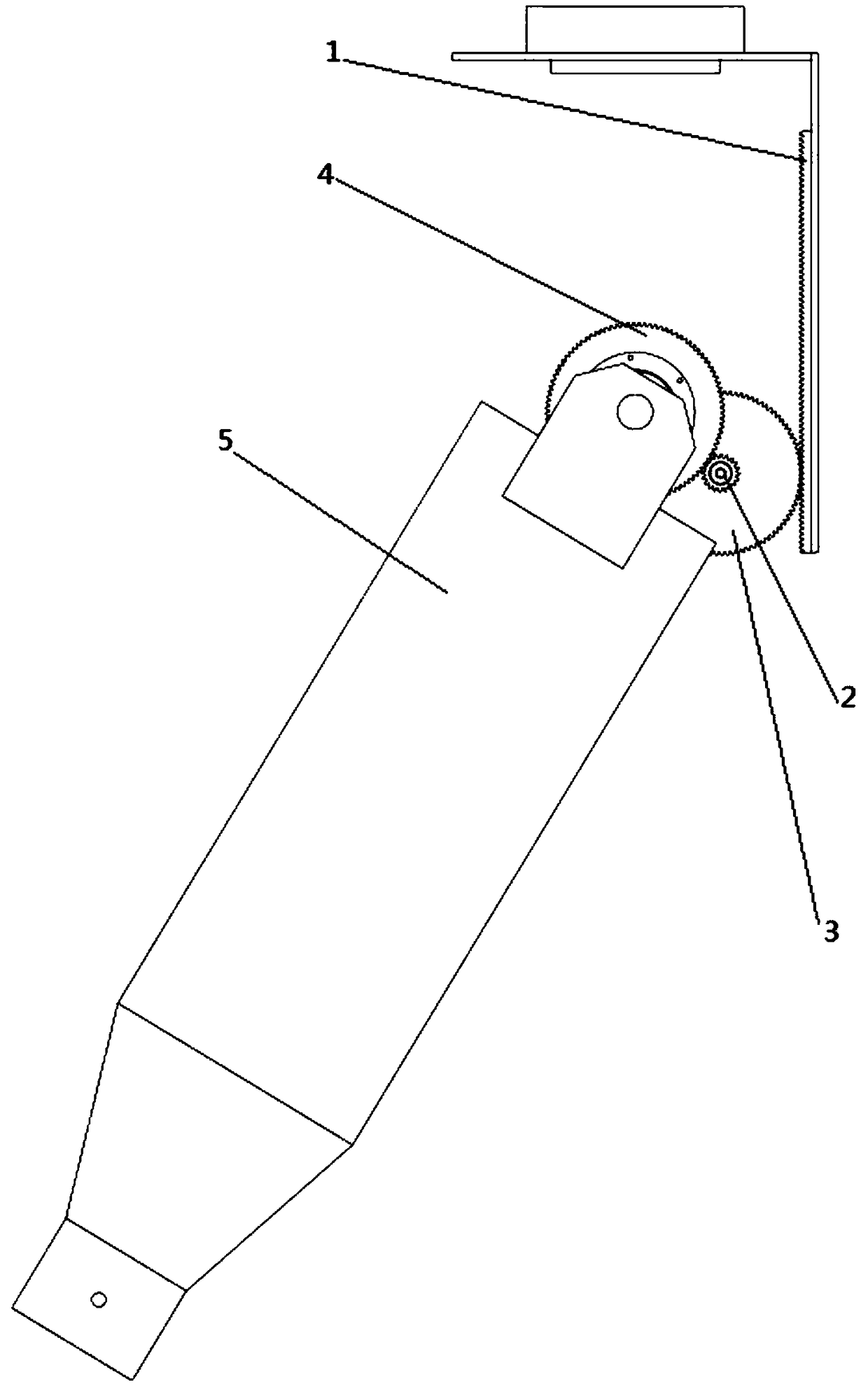

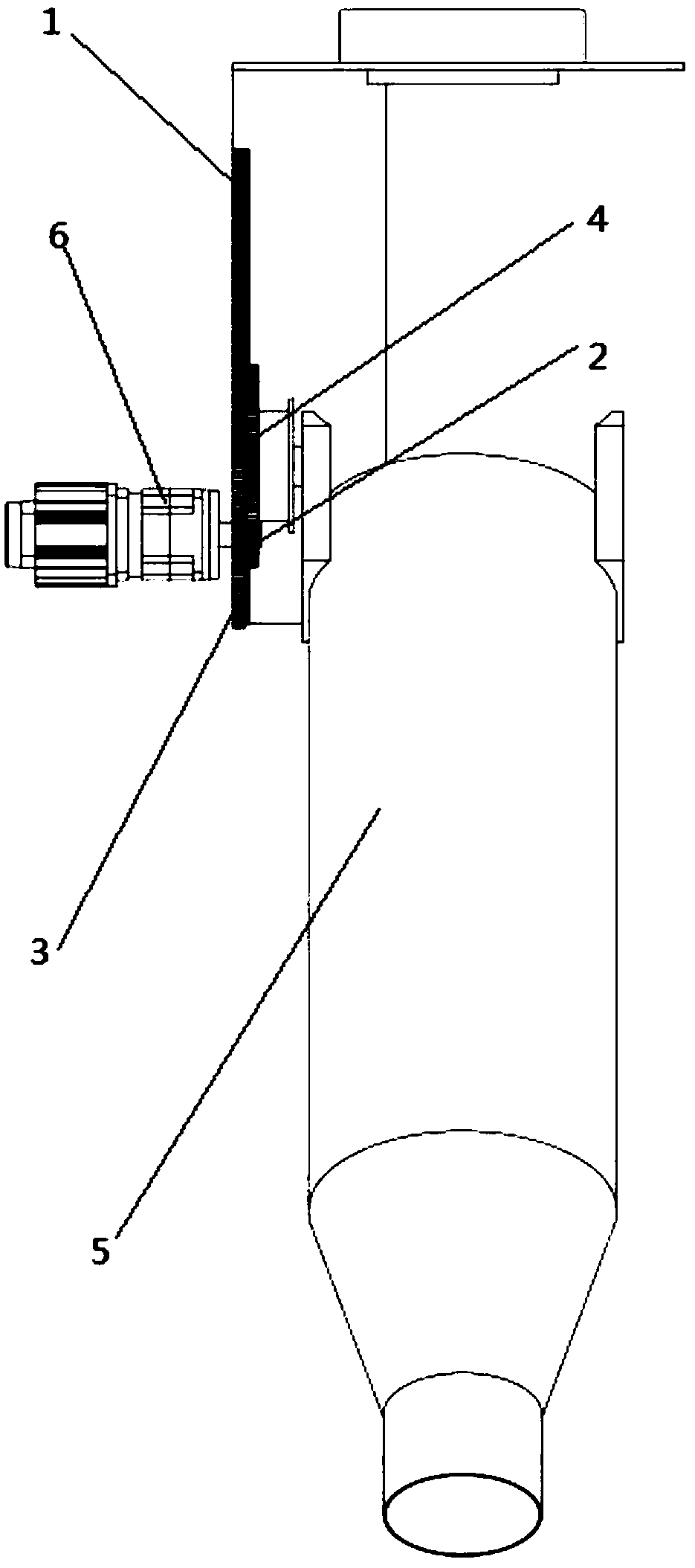

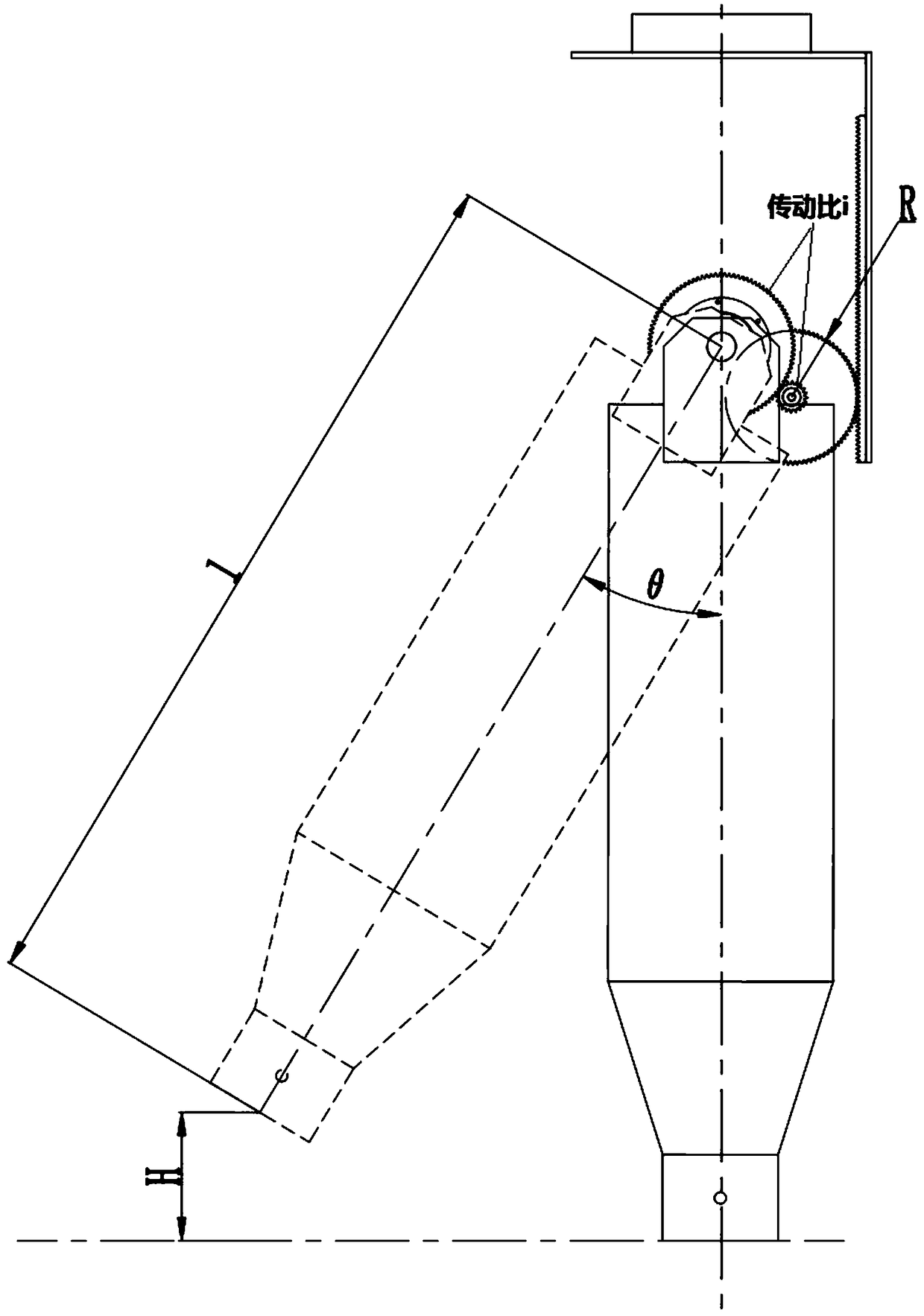

[0016] like figure 1 , figure 2 , image 3 As shown, when the driving wheel (2) (3) of the compensation gear of the present invention rotates counterclockwise under the action of the driving device (6), the driven gear (4) which is externally meshed with the driving wheel Z1 (2) rotates clockwise , the oscillating head (5) is fixedly connected with the driven wheel (4), so the oscillating head (5) swings clockwise, and the head of the oscillating head (5) thus rises. At the same time, since the column with the rack (1) is fixed, the entire swing head moves downward together with the driving wheel Z2 (3), and the rising height of the swing head (5) can be compensated; when the present invention When the driving wheel (2) (3) of the compensating gear set rotates clockwise under the effect of the driving device (6), the above-mentioned moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com