ud non-woven fabric continuous production line

A production line, weft-free technology, applied in the direction of layered products, synthetic resin layered products, other household appliances, etc., can solve the problems of poor traction, tension and conveying effect control, affecting product quality, etc., to achieve tension and conveying. Good control effect, good unwinding effect, and the effect of increasing enterprise benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific content of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

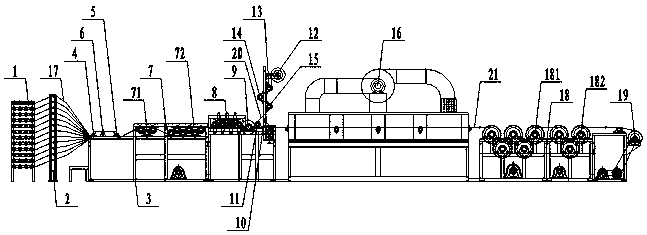

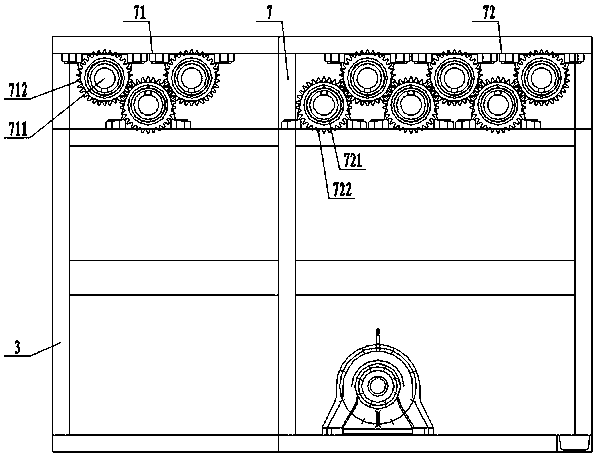

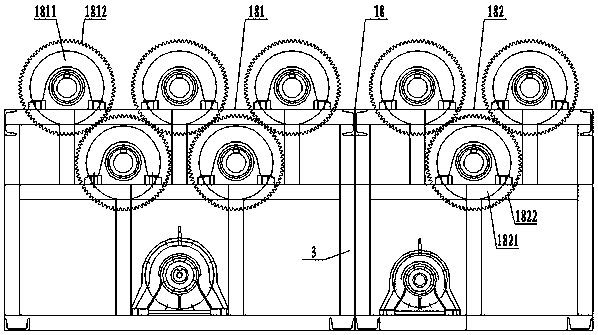

[0013] like figure 1 As shown, the UD non-weft fabric continuous production line includes: a creel 1 arranged at the foremost end, a yarn splitting frame 2 arranged at the rear end of the yarn creel 1, a frame 3 arranged at the rear end of the yarn splitting frame 2, A first tensioner 4 and a second tensioner 5 are respectively arranged at the front end of the spool, and a wire reed 6 is arranged on the frame 3 between the first tensioner 4 and the second tensioner 5. The frame 3 at the rear end of the device 5 is provided with a front traction device 7, the frame 3 at the rear end of the front traction device 7 is provided with a laying roller device 8, and on the frame 3 at the rear end of the laying roller device 8 A glue roller device 9 is provided, a film release roller mounting frame 10 and a composite material gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com