Barrel type tobacco package storage device

A storage device and barrel technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of unable to store cigarette packs, low utilization rate, limited installation location, etc., to avoid the accumulation of cigarette packs, structure streamlined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

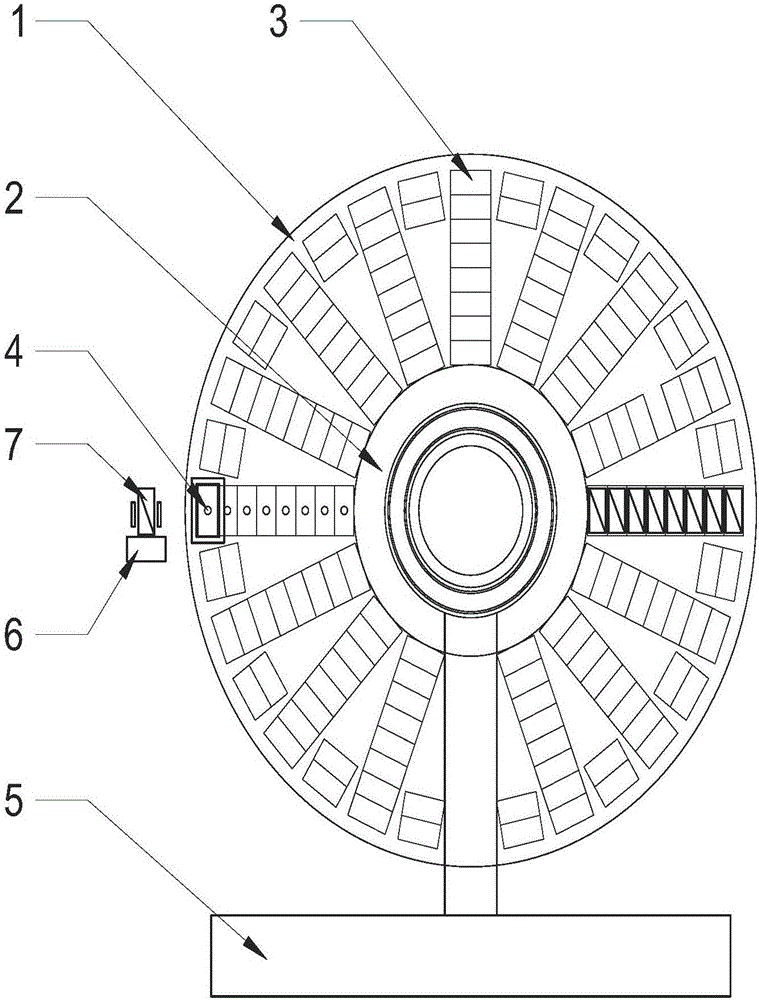

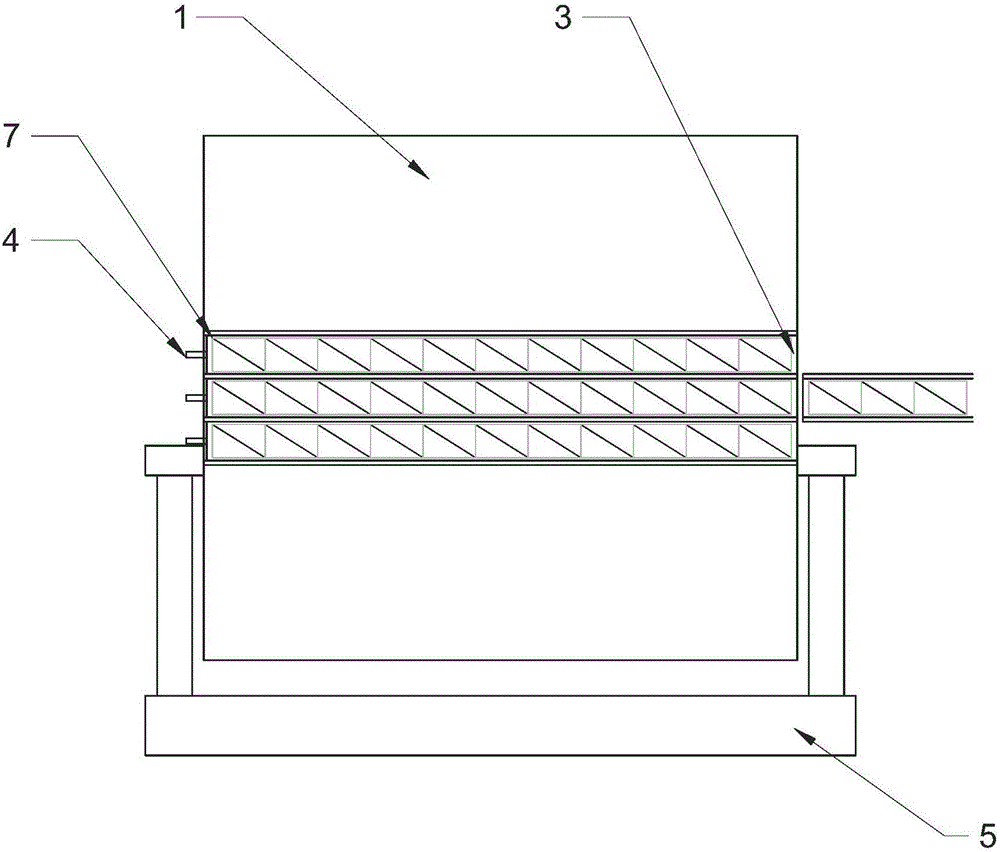

[0017] A kind of drum type cigarette packet storage device of this embodiment, such as figure 1 , 2 As shown, there is a drum body 1 including a drum-type cigarette pack storage device. The drum body 1 is equipped with a rotating disc group 2 driven by a transmission mechanism, and a series of radially divergent cigarette storage boxes are fixed on the rotating disc group 2. The device 3 and the smoke storage device 3 are respectively arranged on several concentric circles with the center of the rotating disk group 2 as the center.

[0018] The smoke storage 3 is a tubular structure, one end of the smoke storage 3 is closed, and an air blowing hole 4 is left on the surface of the closed end, and the air blowing hole 4 is connected with high-pressure gas.

[0019] The round body is installed on the support base 5.

[0020] The drum-type cigarette pack storage device transfers the tobacco rods from the cigarette pack conveying belt 6 to the smoke storage device 3 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com