Resin production filtration system

A filtration system and resin technology, applied in the direction of filtration separation, fixed cartridge filter, chemical instrument and method, etc., can solve the problems of poor resin filtration effect and achieve the effect of ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

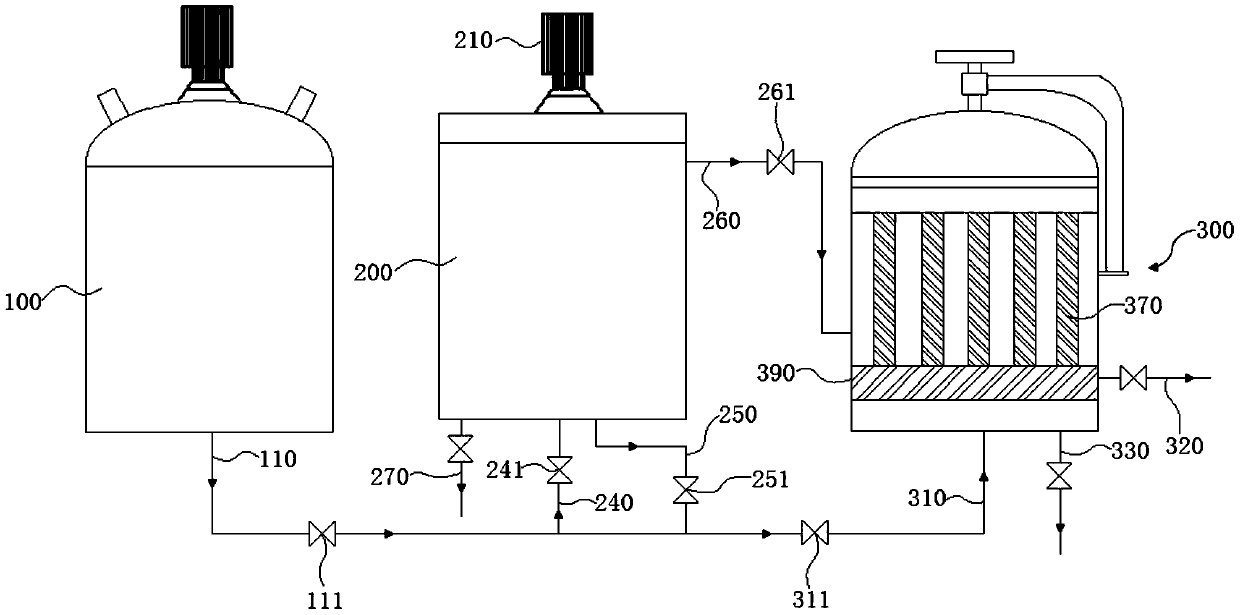

[0038] combine Figure 1-Figure 5 , a filter system for resin production in this embodiment, comprising a diluting kettle 100, the bottom of the diluting kettle 100 is provided with a diluting kettle outlet pipe 110, and the diluting kettle outlet pipe 110 is provided with a diluting kettle outlet valve 111, the paint After the resin in production undergoes a dilution reaction in the dilution kettle 100, the resin entering the filtration system is more uniform, which is helpful for subsequent filtration treatment. , the outlet pipe 110 of the dilution tank is connected with the reactor inlet pipe 240 of the mixing reactor 200 and the filter inlet pipe 310 of the filter 300 respectively, and the reactor outlet pipe 250 is connected with the filter inlet pipe 310 . Such as figure 1As shown, in this embodiment, the reactor inlet pipe 240 and the filter inlet pipe 310 are respectively provided with a reactor inlet valve 241 and a filter inlet valve 311 , and the reactor outlet pi...

Embodiment 2

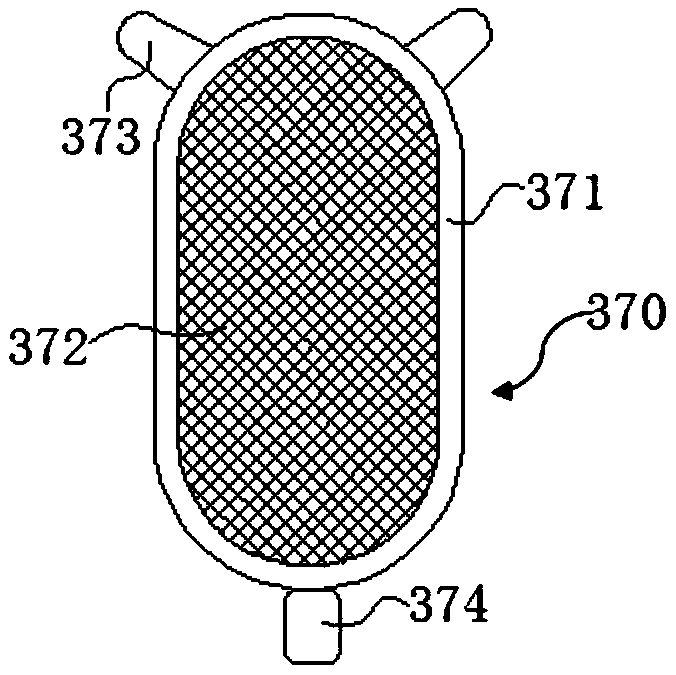

[0042] A kind of resin production filtering system of the present embodiment, its structure is basically the same as embodiment 1, further, as Figure 5 As shown, in the present embodiment, the top of the fixed box 390 is evenly spaced with a plurality of mounting holes 391 along the length direction, and each mounting hole 391 is provided with a filter tube 374, and the diameter of the mounting hole 391 is the same as the outer diameter of the filter tube 374. Matching, and there is also a sealing ring between the installation hole 391 and the filter tube 374, which strengthens the sealing performance between the installation hole 391 and the filter tube 374, and prevents unfiltered resin from directly passing between the installation hole 391 and the filter tube 374. Infiltrate into the fixed box 390 below in the gap between, further ensured filtering effect. A plurality of filter plates 370 are evenly spaced along the radial direction of the filter 300 . A plurality of fil...

Embodiment 3

[0045] A kind of resin production filtering system of the present embodiment, its structure is basically the same as embodiment 1, further, as figure 1 As shown, the upper part of the mixing reactor 200 in this embodiment is also provided with an overflow pipe 260, and the outlet of the overflow pipe 260 is connected to the bottom of the filter 300. When the connecting pipe 250 is discharged into the filter 300, it can be overflowed from the overflow pipe 260 on the upper part of the mixing reactor 200 and discharged into the filter 300, so as to avoid that too much resin accumulated in the mixing reactor 200 cannot flow into the filter 300 in time Internally, the working efficiency of the filtration system is improved.

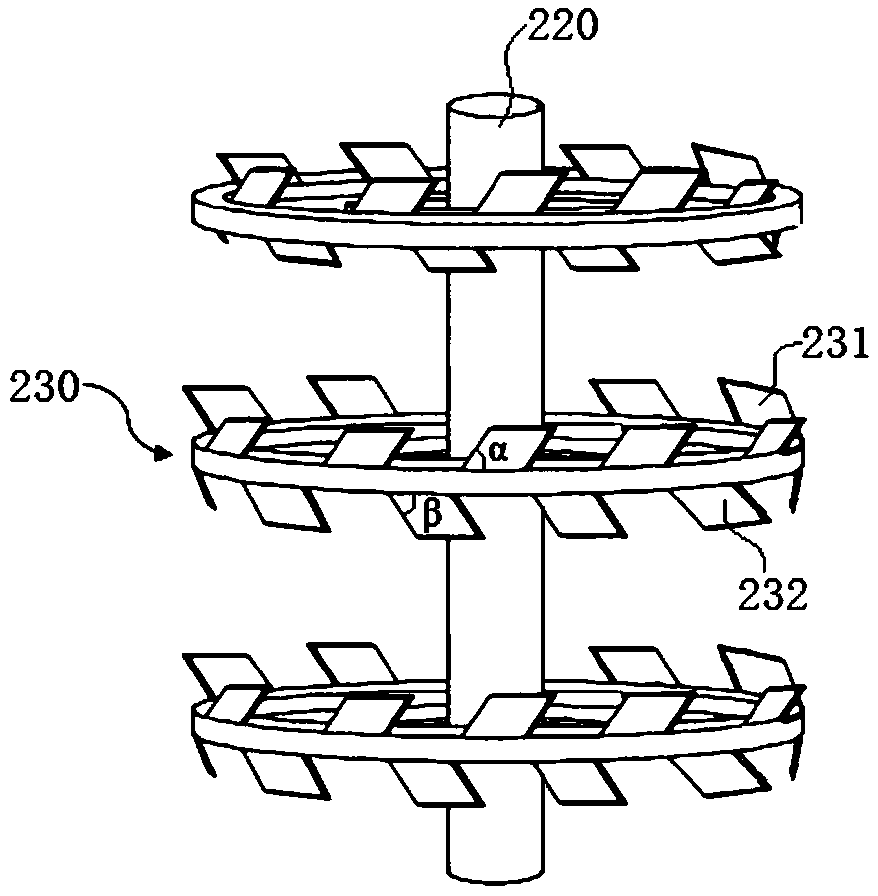

[0046] Such as figure 2 As shown, the upper stirring blade 231 is obliquely arranged on the stirring plate 230, and the angle between the upper stirring blade 231 and the horizontal plane is α, and the range of α is 30°-60°. Specifically, in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com