Dry cleaning agent for automobile maintenance and preparation method thereof

A technology of dry cleaning agent and automobile, applied in the direction of detergent compounding agent, detergent composition, chemical instrument and method, etc., can solve the problems of general cleanliness of car washing, increase of car washing cost, alarming water resources, etc., to reduce drying and Waxing process, saving car washing man-hours, easy to preserve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

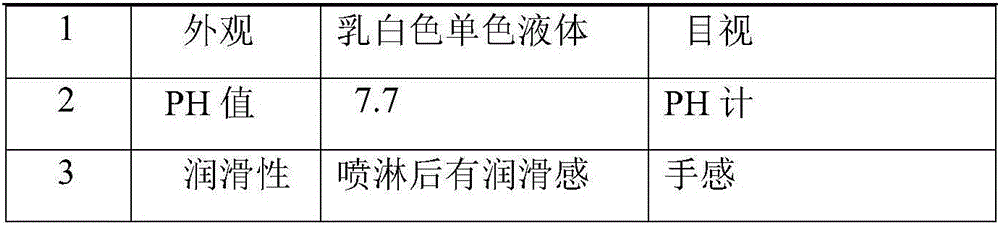

Embodiment 1

[0017] Example 1, a car maintenance dry cleaning agent, which is calculated in parts by weight, its raw material composition and content are as follows: 35 parts of bright wax, 5 parts of penetrating agent, 10 parts of cleaning agent, 8 parts of emulsifier, 1 part of disinfectant parts, essence 0.01 part.

[0018] Among the above-mentioned raw materials, the bright wax can adopt carnauba wax or liquid paraffin; preferably carnauba wax;

[0019] The penetrating agent can use any one or several combinations of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene polyoxypropylene ether, and isomeric alcohol polyoxyethylene ether; preferably fatty alcohol polyoxyethylene ether; or by mass percent Content, fatty alcohol polyoxyethylene ether 60%, fatty alcohol polyoxyethylene polyoxypropylene ether 20%, isomeric alcohol polyoxyethylene ether 20% proportioning combination;

[0020] The cleaning agent can use non-ionic cleaning agents such as coconut oil alkyldiethanol...

Embodiment 2

[0035] Embodiment 2, a car maintenance dry cleaning agent, which is calculated in parts by weight, its raw material composition and content are as follows: 45 parts of bright wax, 7.5 parts of penetrating agent, 22 parts of cleaning agent, 11.5 parts of emulsifier, 2 parts of disinfectant and bactericide parts, essence 0.02 parts.

[0036] Among the above-mentioned raw materials, the bright wax can adopt carnauba wax or liquid paraffin; preferably carnauba wax;

[0037] The penetrating agent can use any one or several combinations of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene polyoxypropylene ether, and isomeric alcohol polyoxyethylene ether; preferably fatty alcohol polyoxyethylene ether; or by mass percent Content, fatty alcohol polyoxyethylene ether 60%, fatty alcohol polyoxyethylene polyoxypropylene ether 20%, isomeric alcohol polyoxyethylene ether 20% proportioning combination;

[0038] The cleaning agent can use non-ionic cleaning agents such as ...

Embodiment 3

[0053] Embodiment 3, a car maintenance dry cleaning agent, which is calculated in parts by weight, its raw material composition and content are as follows: 55 parts of bright wax, 10 parts of penetrant, 18 parts of cleaning agent, 15 parts of emulsifier, 3 parts of disinfectant parts, essence 0.03 parts.

[0054] Among the above-mentioned raw materials, the bright wax can adopt carnauba wax or liquid paraffin; preferably carnauba wax;

[0055] The penetrating agent can use any one or several combinations of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene polyoxypropylene ether, and isomeric alcohol polyoxyethylene ether; preferably fatty alcohol polyoxyethylene ether; or by mass percent Content, fatty alcohol polyoxyethylene ether 60%, fatty alcohol polyoxyethylene polyoxypropylene ether 20%, isomeric alcohol polyoxyethylene ether 20% proportioning combination;

[0056] The cleaning agent can use non-ionic cleaning agents such as coconut oil alkyldiethanola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com