Quickly detachable and connected drill pipe for coal mine

A fast and efficient drill pipe technology, which is applied in the direction of drill pipe, drill pipe, earth square drilling, etc., can solve the problems of troublesome connection, hard to take out pins, non-reversible and other problems, and achieve simple disconnection of drill pipe, high connection efficiency, and improved reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

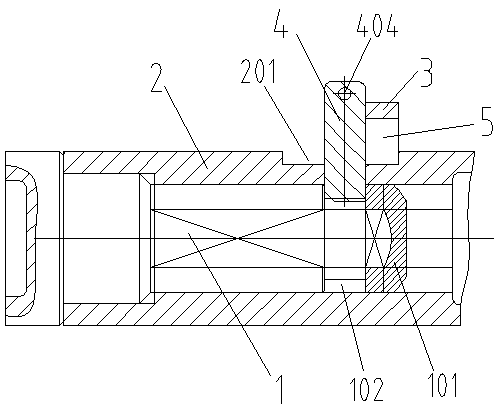

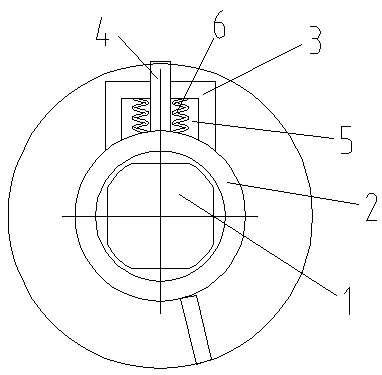

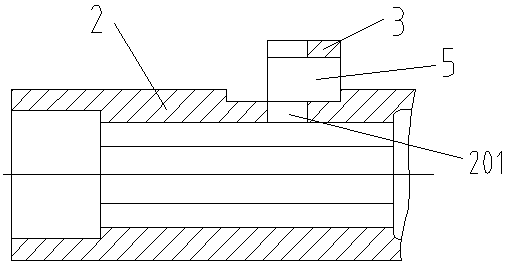

[0018] As shown in the figure, the present invention is a drill pipe that can be quickly disassembled and connected for coal mines. The tail 1 is a square or hexagonal structure for torque transmission, and an inverted U-shaped clamping cap 3 is fixedly arranged on the side wall of the drill storage 2 to form a cavity 5 between the clamping cap 3 and the side wall of the drill storage 2 In the cavity 5, an inserting block 4 is vertically slidably arranged. The inserting block 4 is composed of a square limiting block 401 and a pin rod 402 arranged on the square limiting block 401. The square limiting block 401 at the bottom of the inserting block 4 passes through The square hole 201 matched with the square stop block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com