Continuous negative pressure sand washing device and system thereof

A technology of sand washing and negative pressure, which is applied in the field of continuous negative pressure sand washing device and its system, and can solve the problems that sand washing is easy to pollute the oil layer and construction efficiency is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

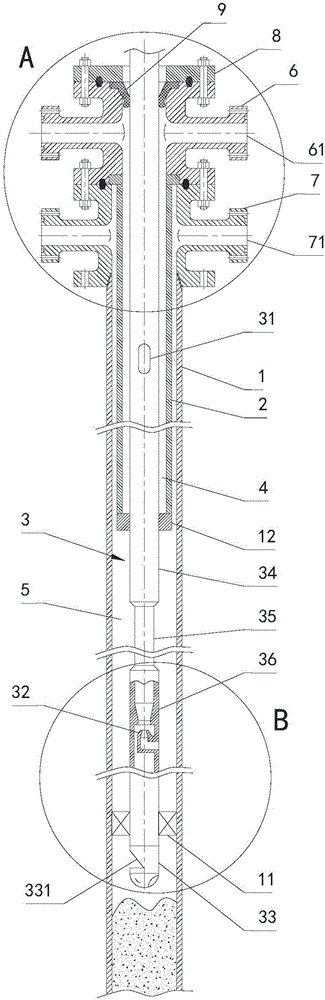

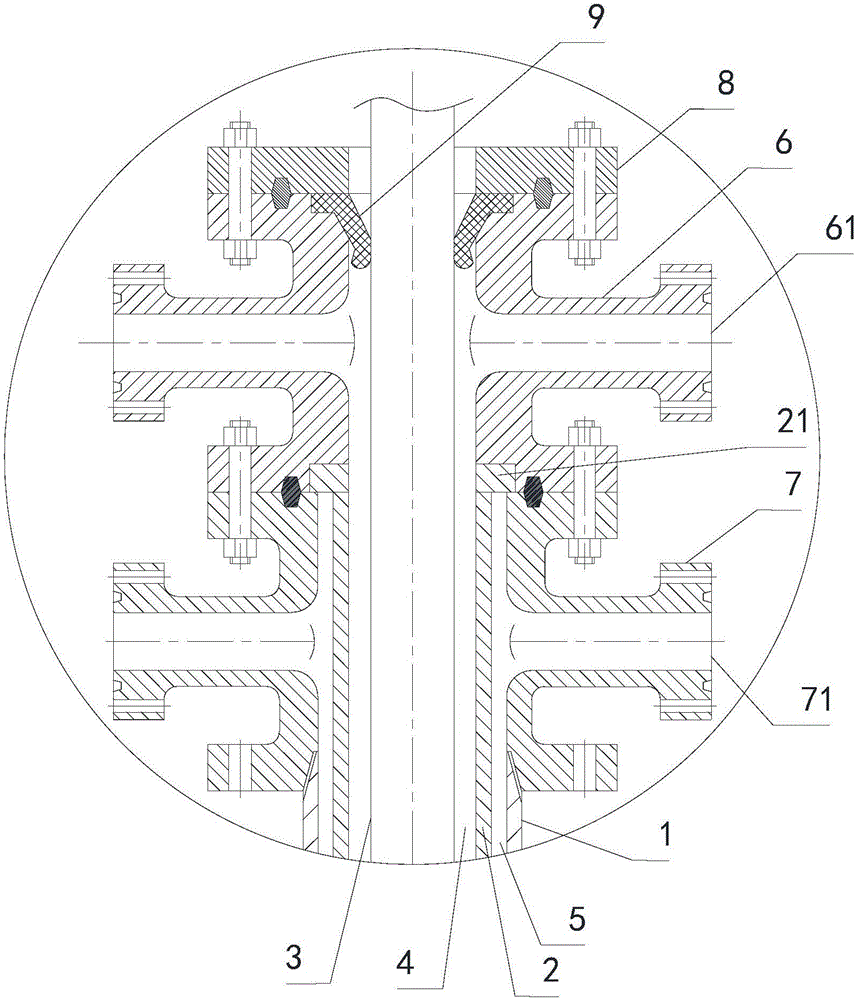

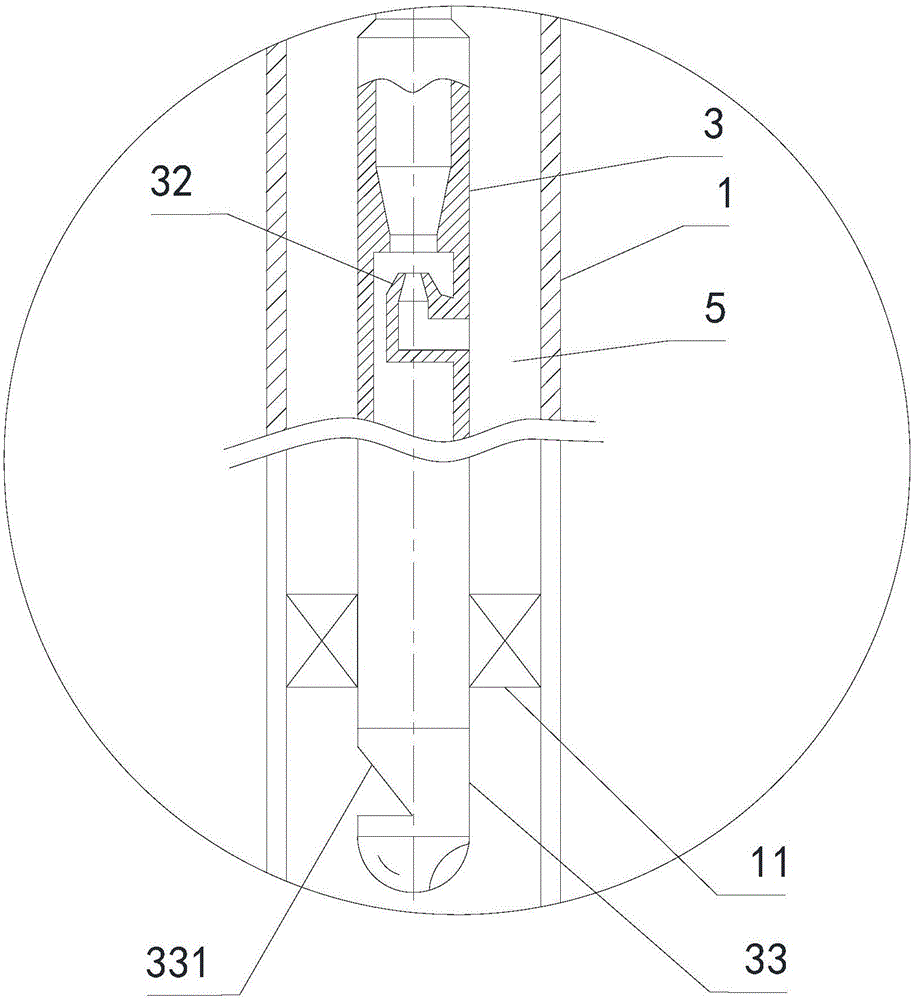

[0045] see Figure 1-Figure 3 As shown, the present embodiment provides a continuous negative pressure sand washing device; figure 1 Schematic diagram of the structure of the continuous negative pressure sand washing device provided in this embodiment; figure 2 for figure 1 The partial enlarged view of area A of the continuous negative pressure sand washing device shown; image 3 for figure 1 The partial enlarged view of area B of the continuous negative pressure sand washing device shown.

[0046] see Figure 1-Figure 3 As shown, the continuous negative pressure sand washing device provided in this embodiment includes a casing 1, a liner 2 and a sand washing pipe 3 arranged sequentially from outside to inside; that is, the casing 1 is placed outside the liner 2, and the liner 2 coats are placed on the outside of the sand washing pipe 3. Preferably, the casing 1 is relatively fixed relative to the liner 2 .

[0047] Sand washing pipe 3 is provided with guide hole 31, j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com