Novel vibration and noise reducing expansion valve

A technology of vibration reduction and noise reduction, expansion valve, applied in the field of expansion valve, to achieve the effect of ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

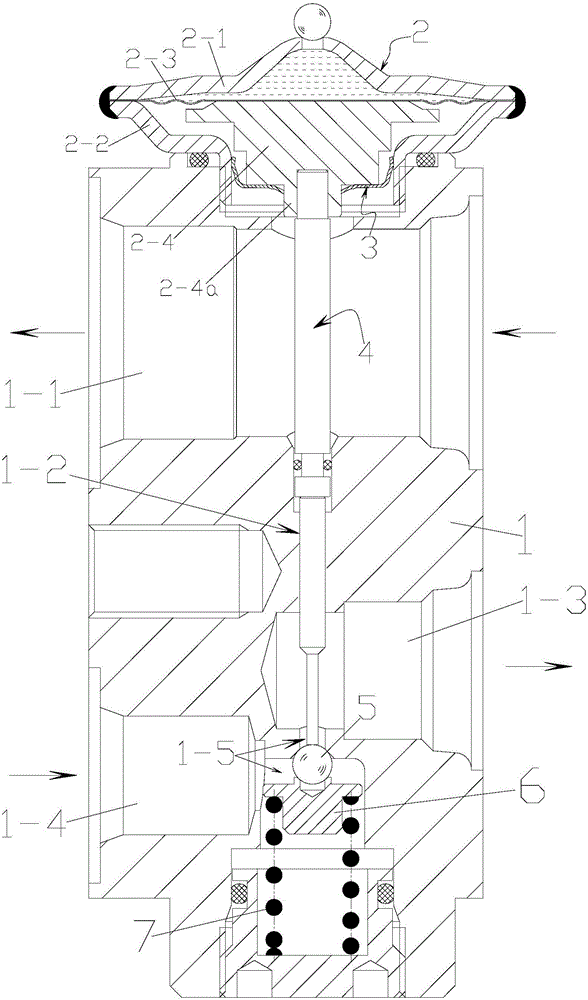

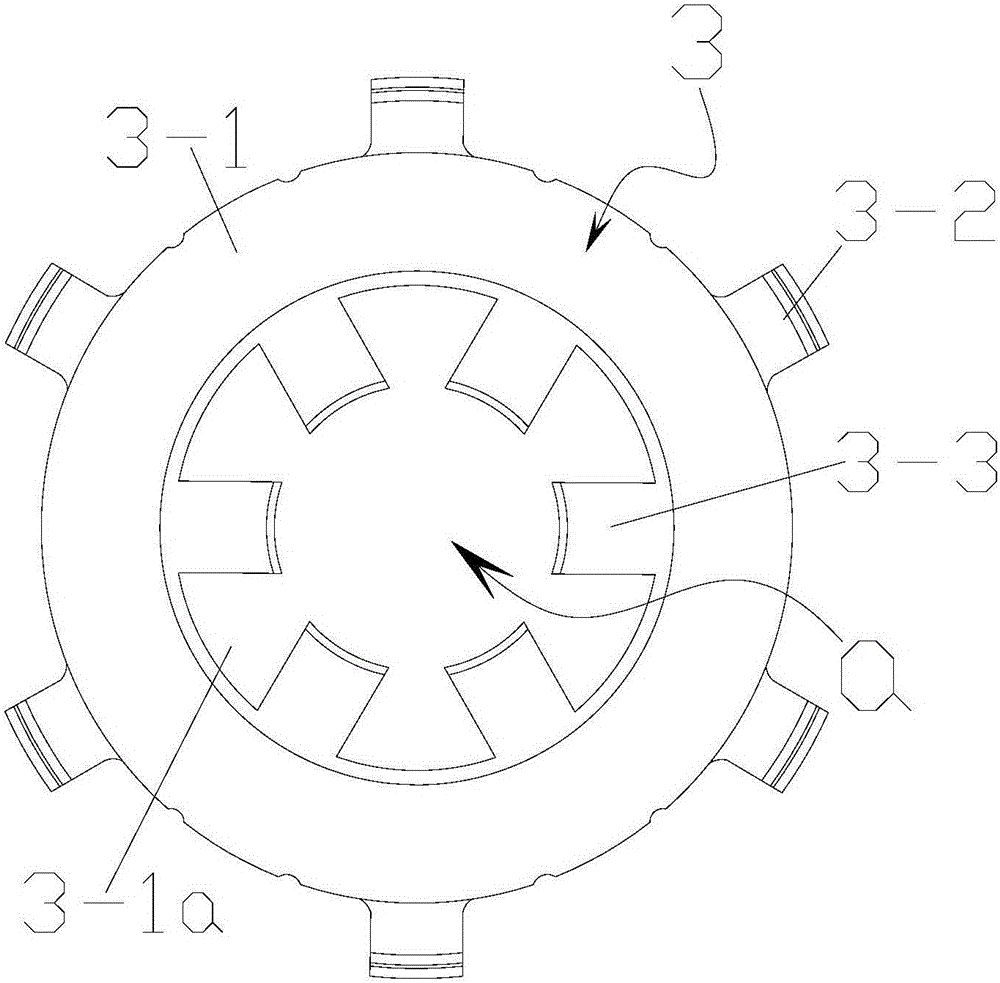

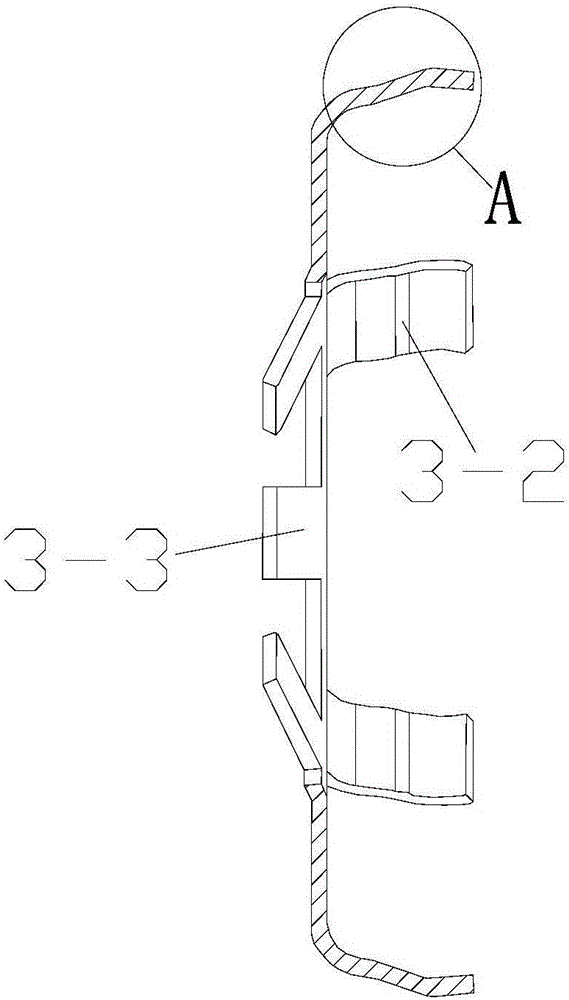

[0026] Refer to attached figure 1 , 2 , 3, 4: This new type of vibration-reducing and noise-reducing expansion valve includes a valve body 1, a thermal head assembly 2 installed on the top of the valve body 1, and the thermal head assembly 2 includes an upper cover 2-1 and a lower cover 2- 2. A diaphragm 2-3 is fixed between the upper cover 2-1 and the lower cover 2-2, which can be changed according to the temperature and pressure of the refrigerant from the evaporator. There is a push block 2-4 under the diaphragm 2-3, and the lower Cover 2-2 is provided with anti-vibration clip 3, and anti-vibration clip 3 fits on the inner wall of lower cover 2-2 and can move up and down at lower cover 2-2; Anti-vibration clip 3 includes substrate 3-1, at least three The cloth is fixed on the outer contour surface of the substrate 3-1 and is an elastic sheet 3-2 that is bent and arranged. The elastic sheet 3-2 is elastically pressed on the inner wall of the lower cover 2-2, and the center ...

Embodiment 2

[0034] Refer to attached Figure 5 , 6, 7, 8: This new type of vibration-reducing and noise-reducing expansion valve includes a valve body 1, a thermal head assembly 2 installed on the top of the valve body 1, and the thermal head assembly 2 includes an upper cover 2-1 and a lower cover 2- 2. A diaphragm 2-3 is fixed between the upper cover 2-1 and the lower cover 2-2, which can be changed according to the temperature and pressure of the refrigerant from the evaporator. There is a push block 2-4 under the diaphragm 2-3, and the lower Cover 2-2 is provided with anti-vibration clip 3, and anti-vibration clip 3 fits on the inner wall of lower cover 2-2 and can move up and down at lower cover 2-2; Anti-vibration clip 3 includes substrate 3-1, at least three The cloth is fixed on the outer contour surface of the substrate 3-1 and is an elastic sheet 3-2 that is bent and arranged. The elastic sheet 3-2 is elastically pressed on the inner wall of the lower cover 2-2, and the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com