Rotating type bottle holder structure and refrigerator

A rotary, bottle holder technology, used in lighting and heating equipment, cooling fluid circulation devices, household appliances, etc., can solve the problems of fixed bottle holders, reduced available space, and occupation of internal space of the box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

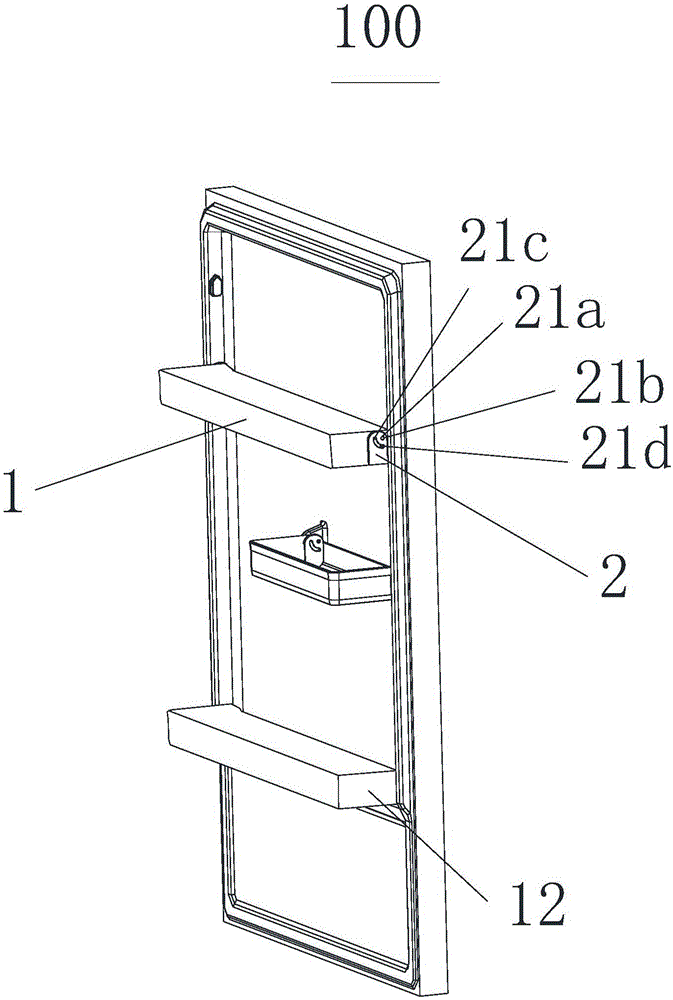

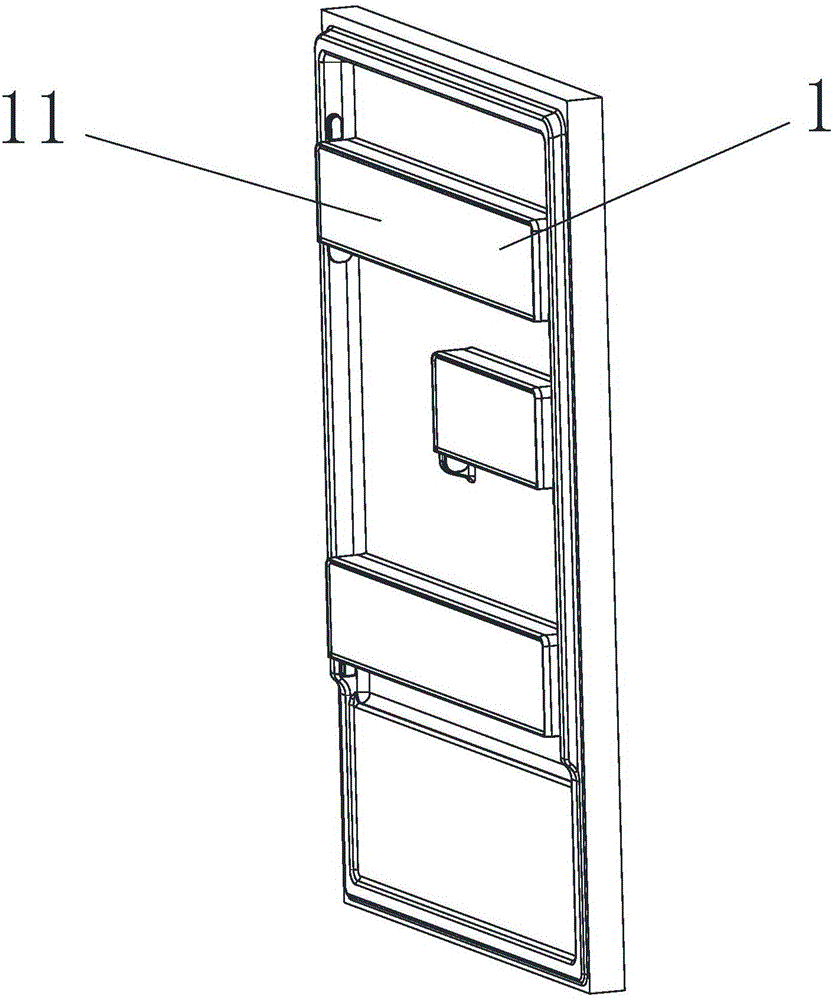

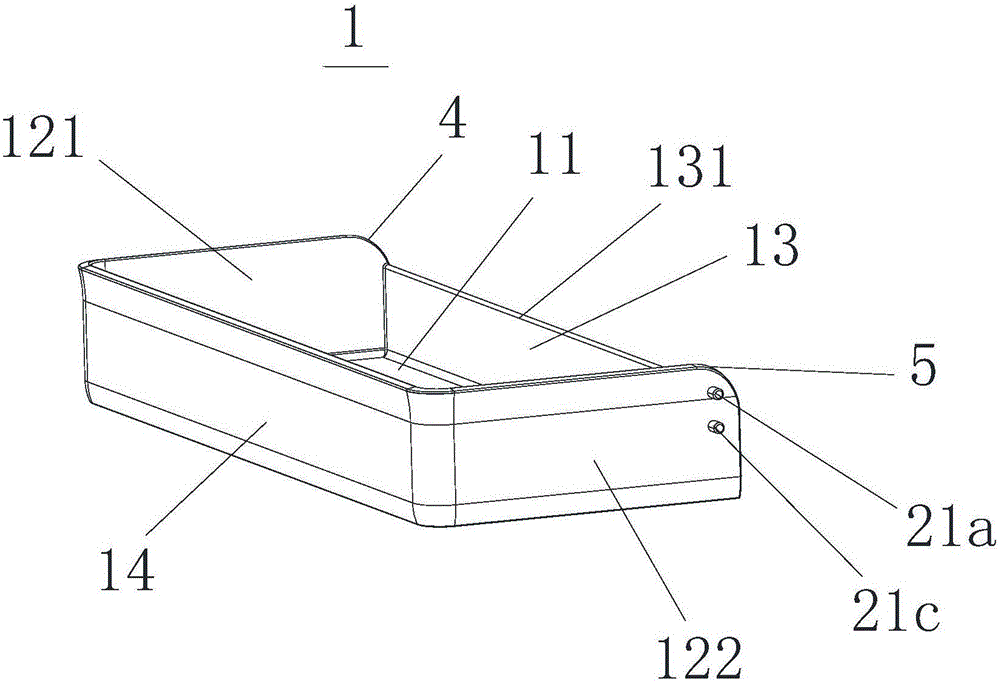

[0032] Embodiment 1: a fixed rotating shaft 21a and a sliding rotating shaft 21c are arranged on the outer surface of the side plate 12 adjacent to the end of the rear side plate 13 at the left and right ends of the bottom plate 11. The fixed rotating shaft hole 21b and the rotating groove 21d are spaced apart. The fixed rotating shaft 21a is rotatably fitted in the fixed rotating shaft hole 21b, and the sliding rotating shaft 21c is slidably fitted in the rotating groove 21d. The rotating shaft 21a rotates in the fixed rotating shaft hole 21b and makes the sliding rotating shaft 21c reciprocally slide in the rotating groove 21d. When the sliding rotating shaft 21c matches the engaging part 3, the rotary bottle holder 1 changes from the original horizontal position to the vertical position. straight position. It should be noted that the above-mentioned fixed rotating shaft 21 a and sliding rotating shaft 21 c are provided on the left side board 121 and the right side board 122...

Embodiment 2

[0033]Embodiment 2: On the outer surface of the side plate 12 at the left and right ends of the base plate 11, adjacent to the end of the rear side plate 13, spaced apart fixed shaft holes 21b and rotation grooves 21d are provided. A fixed shaft 21a and a sliding shaft 21c are respectively constructed on the top, wherein the fixed shaft 21a is rotatably fitted in the fixed shaft hole 21b, and the sliding shaft 21c is slidably fitted in the rotating groove 21d, and the rotating bottle holder 1 is fixed to The rotating shaft 21a rotates in the fixed rotating shaft hole 21b and makes the sliding rotating shaft 21c reciprocally slide in the rotating groove 21d. When the sliding rotating shaft 21c matches the engaging part 3, the rotary bottle holder 1 changes from the original horizontal position to the vertical position. straight position. It should be noted that the above-mentioned fixed shaft hole 21 b and the rotation groove 21 d are provided on the left side plate 121 and the...

Embodiment 3

[0034] Embodiment 3: On the outer surface of the end of the side plate 12 adjacent to the rear side plate 13 at the left and right ends of the bottom plate 11, spaced apart fixed rotating shafts 21a and rotating grooves 21d are provided. On the bottle holder fixed plate 2 A fixed shaft hole 21b and a sliding shaft 21c are respectively configured, wherein the fixed shaft 21a is rotatably fitted in the fixed shaft hole 21b, and the sliding shaft 21c is slidably fitted in the rotating groove 21d, and the rotating bottle holder 1 is fixed so as to The rotating shaft 21a rotates in the fixed rotating shaft hole 21b and makes the sliding rotating shaft 21c reciprocally slide in the rotating groove 21d. When the sliding rotating shaft 21c matches the engaging part 3, the rotary bottle holder 1 changes from the original horizontal position to the vertical position. straight position. It should be noted that the above-mentioned fixed rotating shaft 21 a and rotating groove 21 d are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com