Artificial board automatic inspection machine

An automatic inspection and artificial panel technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low efficiency of manual inspection technology, unstable inspection results, time-consuming and labor-intensive, etc., to improve the consistency of inspection and reduce the number of inspections. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

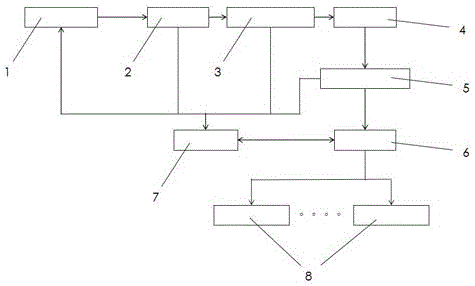

[0039] A wood-based panel automatic inspection machine, such as figure 1 As shown, it includes an analysis control system 7 and an automatic board feeder 1 , a weighing device 2 , a thickness detection device 3 , an orientation device 4 , a surface scanning device 5 , a board separating device 6 , and an automatic palletizer 8 connected in sequence. The analysis control system includes: a control part and an analysis part.

[0040] The control part receives the data from the weighing device 2 , the thickness detection device 3 , the surface scanning device 5 and the board separating device 6 , analyzes and obtains a board feeding control command, and sends the board feeding control command to the automatic board feeding machine 1 .

[0041] After receiving the data sent by the weighing device 2 , the thickness detection device 3 and the surface scanning device 5 , the analyzing part analyzes and obtains a board splitting control command, and sends the board splitting control c...

Embodiment 2

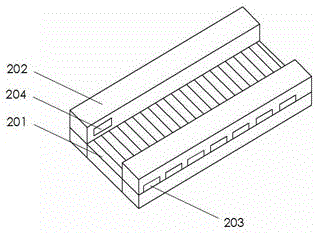

[0045] A wood-based panel automatic inspection machine, such as figure 1 As shown, it includes an analysis control system 7 and an automatic board feeder 1 , a weighing device 2 , a thickness detection device 3 , an orientation device 4 , a surface scanning device 5 , a board separating device 6 , and an automatic palletizer 8 connected in sequence. Such as figure 2 As shown, the weighing device 2 includes a first transport device 201 and two first fixing frames 202 . The first transport device 201 is provided with a first fixing frame 202 on both sides along the transport direction. The first fixing frame 202 is located above the first transportation device 201 . Ten tension sensors 203 are arranged in the first fixing frame 202 . The sensing part of the tension sensor 203 is fixedly connected with the first transportation device 201 . The tension sensor 203 is in signal connection with the analysis control system 7 . The weighing device 2 is provided with a first infra...

Embodiment 3

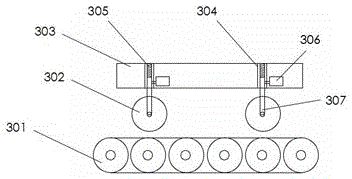

[0048] A wood-based panel automatic inspection machine, such as figure 1 As shown, it includes an analysis control system 7 and an automatic board feeder 1 , a weighing device 2 , a thickness detection device 3 , an orientation device 4 , a surface scanning device 5 , a board separating device 6 , and an automatic palletizer 8 connected in sequence. Such as image 3 As shown, the thickness detection device 3 includes a second transportation device 301 , rollers 302 , a second fixing frame 303 and a displacement measuring device 306 . The second fixing frame 303 is located above the second transportation device 301 , and on an end face facing the second transportation device 301 , a first groove 304 is provided along the vertical direction. A first connecting rod 307 is disposed in the first groove 304 . One end of the first connecting rod 307 is fixedly connected to the inner wall of the second fixed frame 303 through the first spring 305, and the other end extends between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com