Water test table for toilet bowls

A technology for a water test stand and a toilet is applied in the field of toilet flushing performance testing devices, which can solve the problems of insufficient water pressure and the inability of water to be smoothly drawn into the toilet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

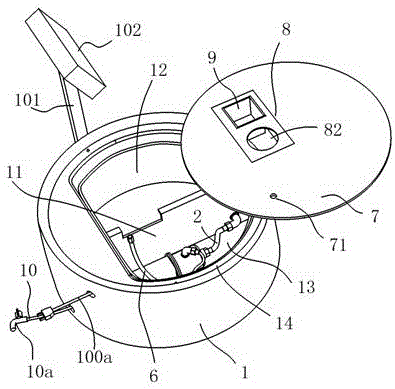

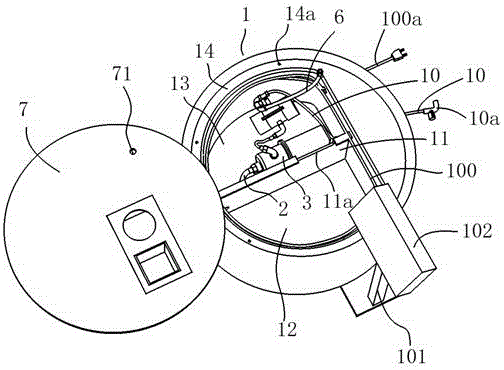

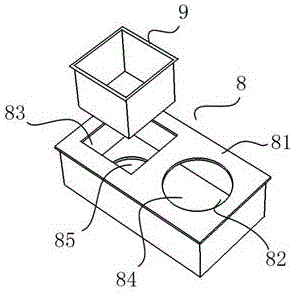

[0021] like Figure 1-4 Shown is a toilet water testing platform of the present invention, comprising a housing 1, a suction pipe 2, a water pump 3, a connecting pipe 4, a pressurized tank 5, a water inlet pipe 6, a support plate 7, a drainage box 8 and a basket 9, and the housing 1 The water storage chamber 12 and the pump chamber 13 are separated by the isolation plate 11. The upper opening of the housing 1 is provided with a support platform 14 along the inner edge. The water pump 3 is installed in the pump chamber 13, and one end of the suction pipe 2 is installed on the isolation plate. The bottom of 11 communicates with the water storage chamber 12, the other end of the suction pipe 2 is connected to the pump inlet of the water pump 3, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com