Low-oscillation dispersion mirror structure and design method thereof

A dispersive mirror and low-dispersion technology, applied in the field of low-oscillation dispersive mirror structure, can solve the problems of large design engineering and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

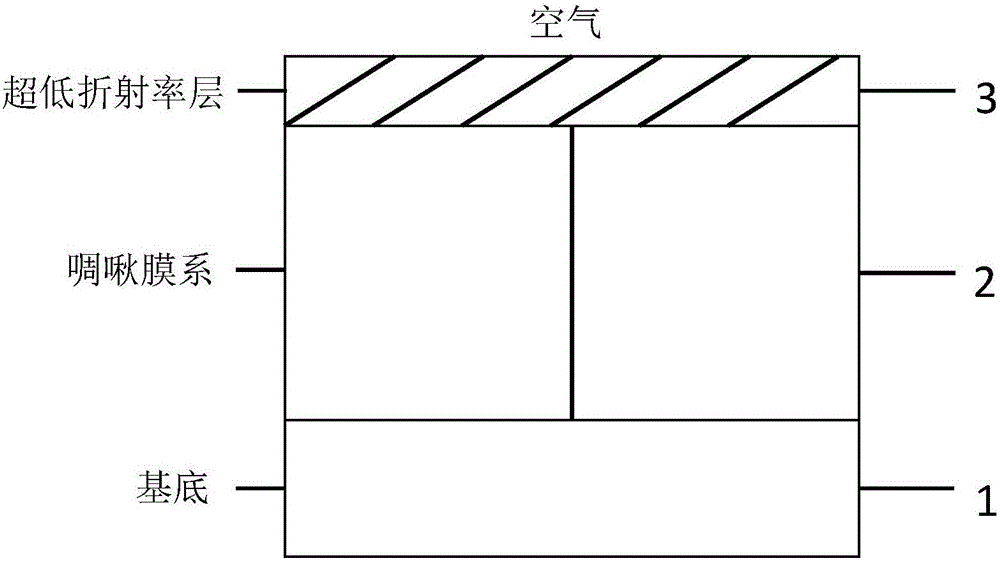

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

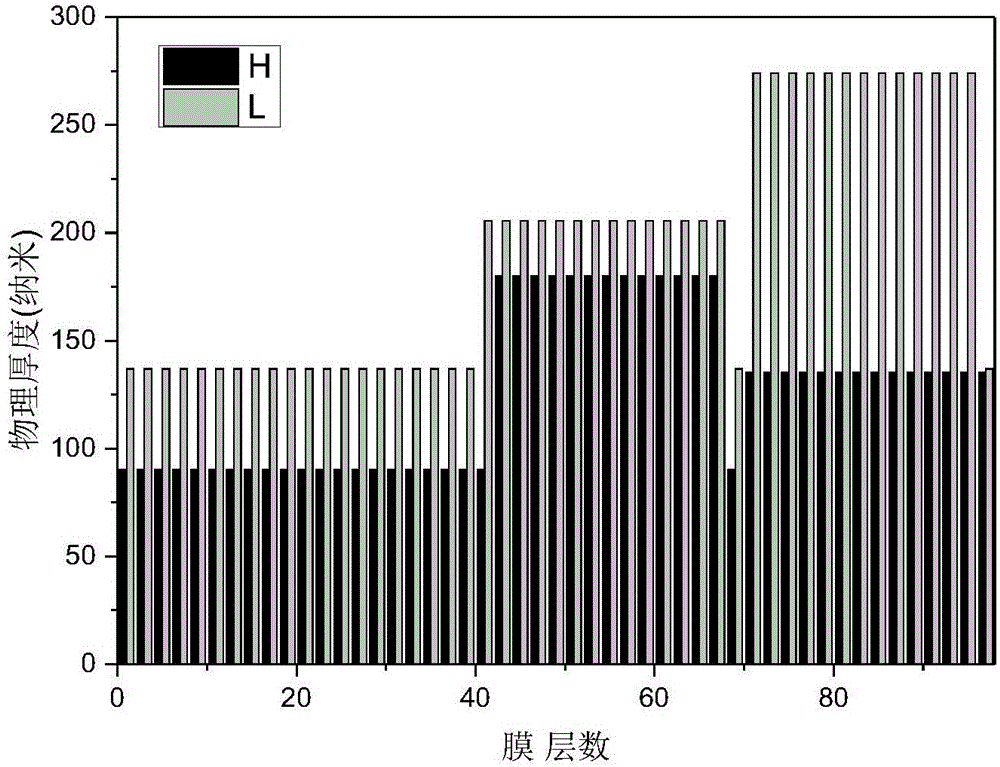

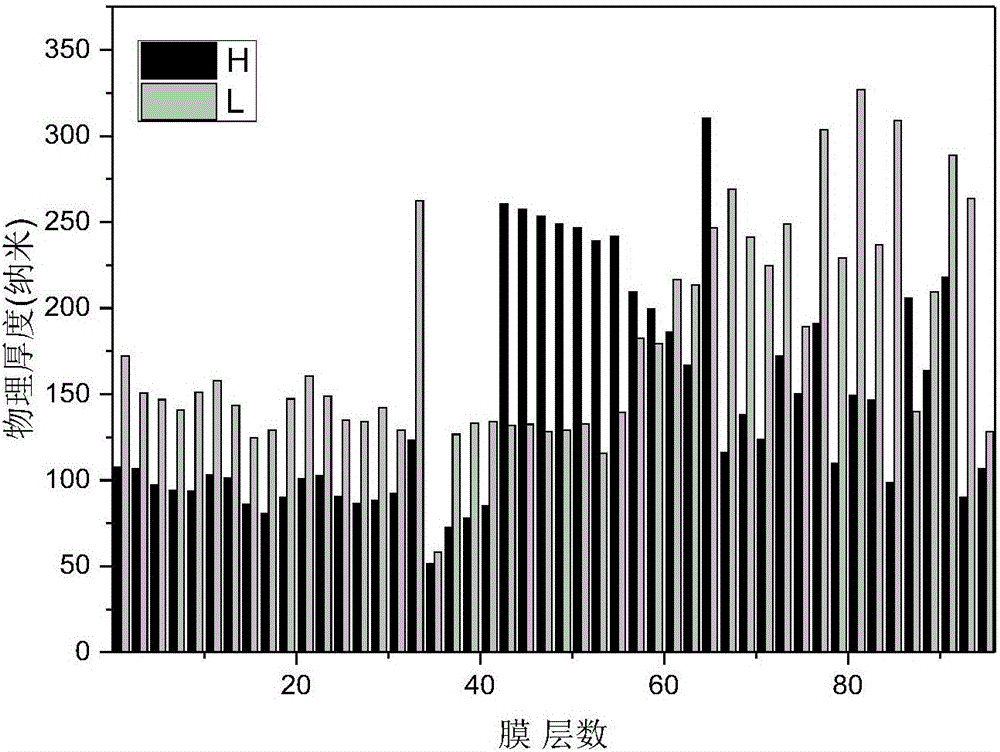

[0031] The low oscillation dispersion mirror index required by Embodiment 1 is: group delay dispersion value -200fs 2 , Reflectivity > 99.8%, corresponding bandwidth is 800nm central wavelength 200nm bandwidth.

[0032] The design steps are as follows:

[0033] 1. According to the group delay dispersion and bandwidth requirements, the amount of dispersion is relatively large and the bandwidth is wide, so the high refractive index material Nb with a high refractive index is selected 2 o 5 , the low refractive index material is SiO 2 , the refractive index parameters of high and low refractive index materials are given by the Cauchy formula Sure.

[0034] 2. According to the requirements of the low-oscillation dispersion mirror, select appropriate parameters and substitute them into the film structure expression G / (HL)^n(HL)^m(HxLH)^k(LxHL)^kM / A of the low-oscillation dispersion mirror, The film structure is obtained as figure 2 mentioned.

[0035]3. Based on the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com