A bim-based treatment method for steel bars at cross-steel column-beam joints

A technology of beam reinforcement and steel column, which is applied in the field of reinforcement treatment at cross steel column-beam joints based on BIM, can solve the problems that affect the quality of the project, and the beam reinforcement cannot extend into the stiff column steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

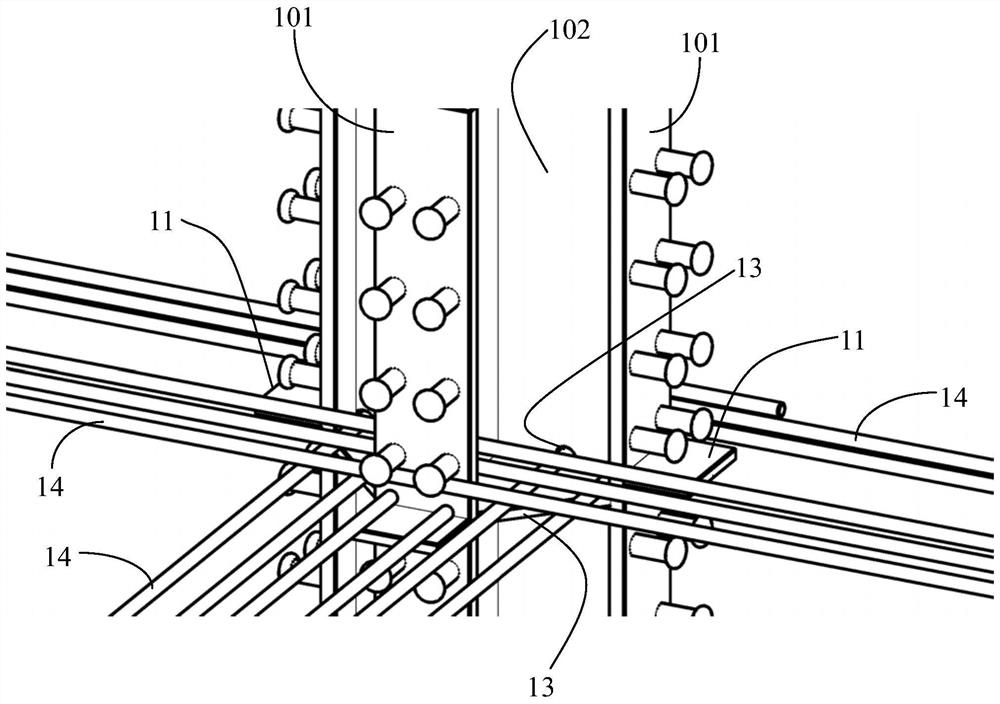

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

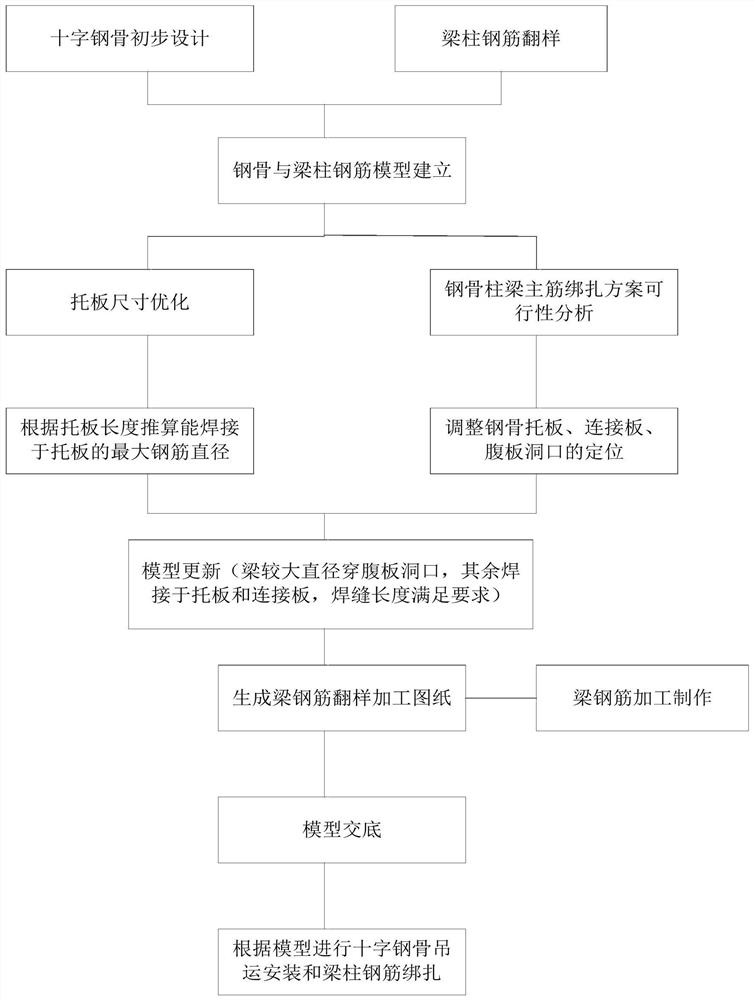

[0033] The traditional method of processing steel bars at the joints of columns and beams with cross steel frames is to roughly set out the beam steel bars according to the position of the cross steel frames by an experienced steel bar master. When the steel bar is welded to the supporting plate at the flange of the cross steel frame or the connecting plate between the webs of the cross steel frame, the weld length cannot meet the requirements, so it is necessary to simulate the lofting of the beam reinforcement in advance.

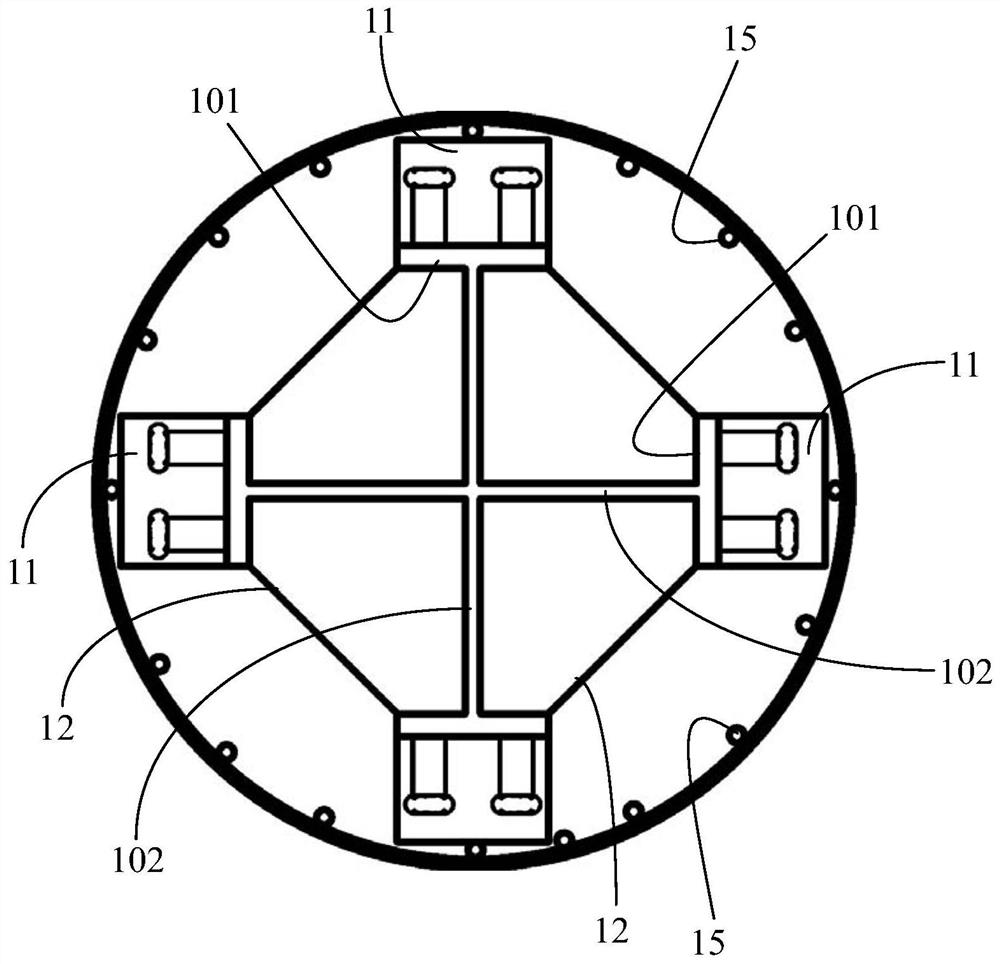

[0034] The present invention is based on the BIM-based method for processing the steel bars at the joints of the cross steel frame columns and beams. Through BIM technology, the steel bars of the columns and beams at the cross steel frame beams are simulated in advance. Set the connecting plate at the appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com