Toaster heating body winding machine

A heating element and winding machine technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of high labor intensity, low wire winding quality, and long wire winding time, so as to improve market competitiveness, The effect of improving the general rate and lowering the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

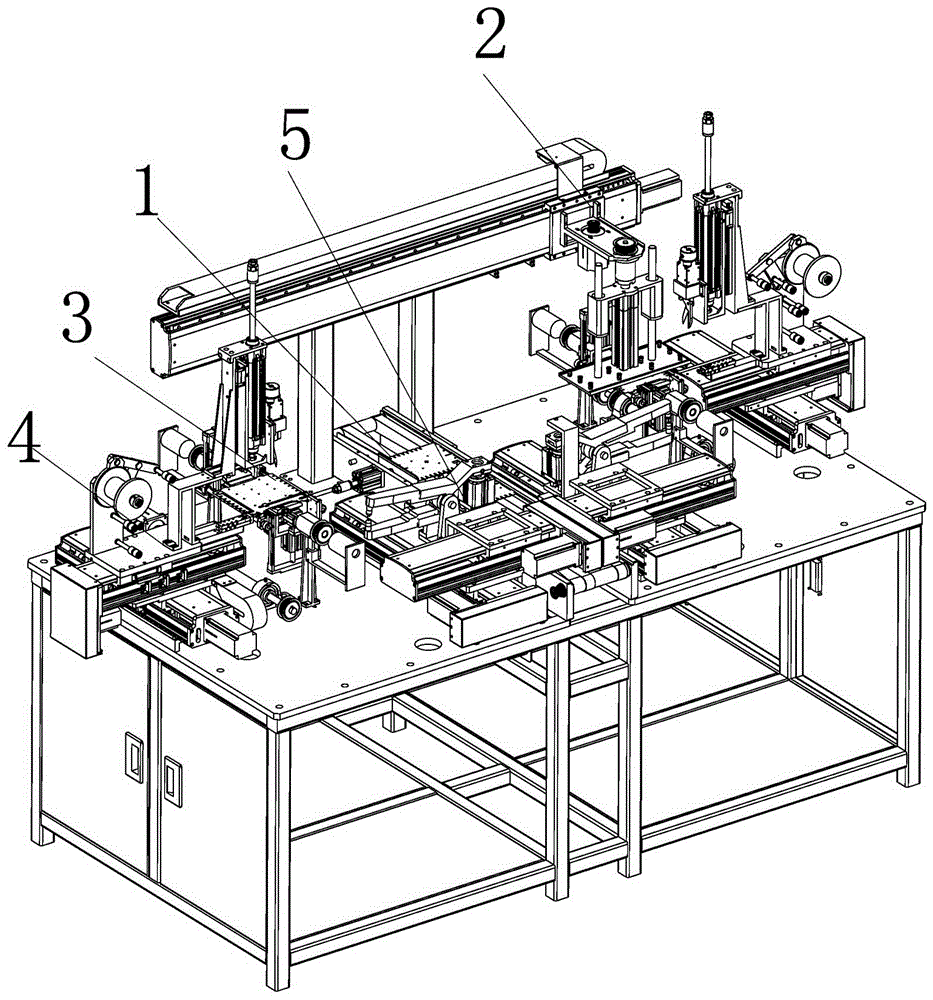

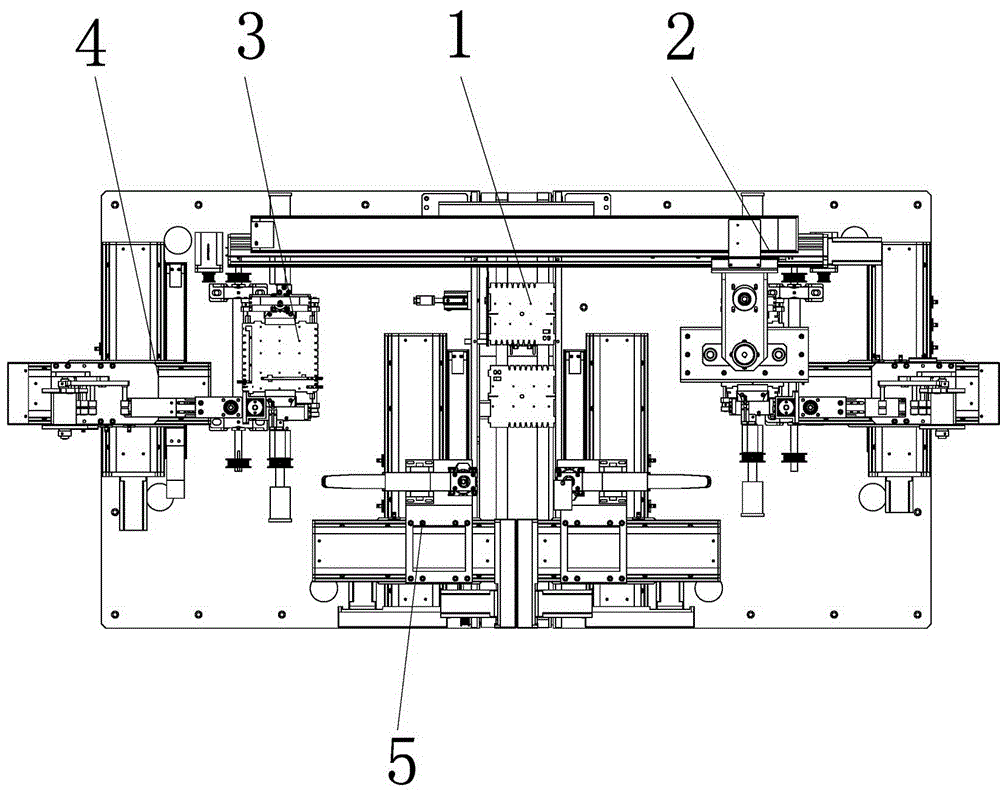

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings. A toaster heating body winding machine is characterized in that: it comprises a feeding mechanism 1, a reclaiming mechanism 2, a winding mechanism 3, a wire feeding mechanism 4, and a welding mechanism 5, wherein:

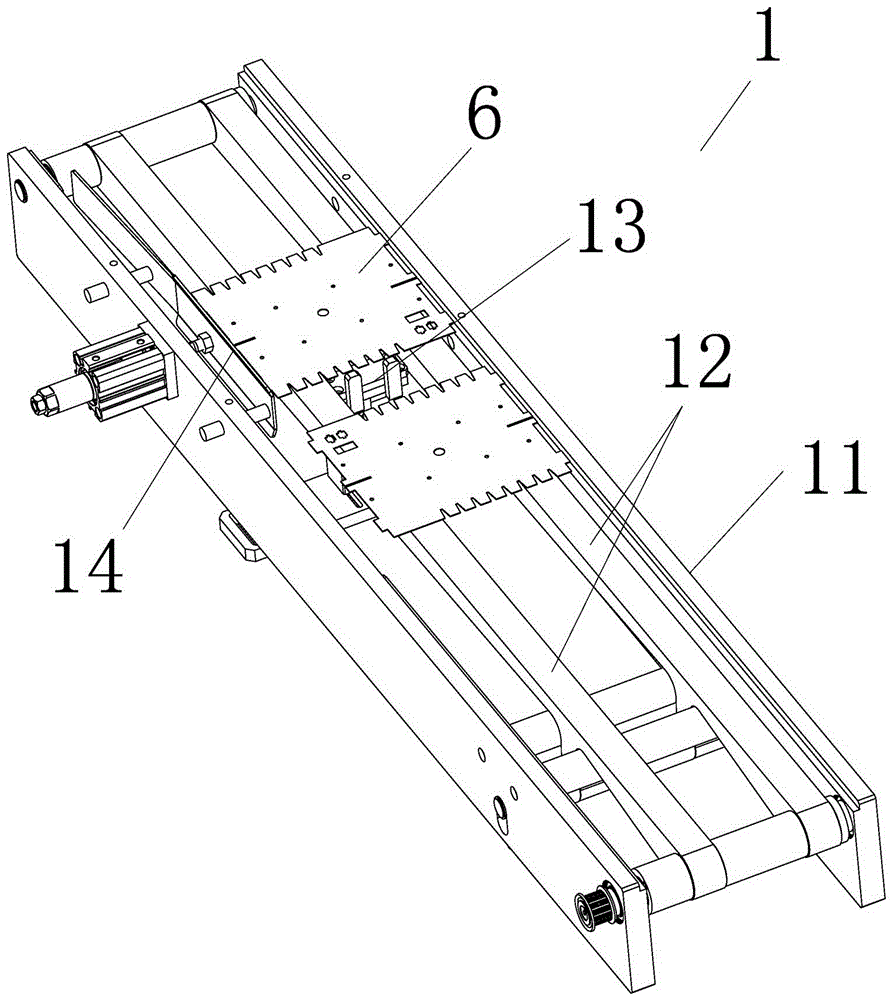

[0032] The feeding mechanism 1 includes a feeding frame 11 and a feeding belt 12 arranged therein. The feeding belt 12 is driven by a power mechanism to move and is connected to the assembly line. The feeding frame 11 is also provided with a positioning baffle 13 and a positioning plate 12. The push plate 14, the positioning baffle 13 and the positioning push plate 14 play a role in positioning the insulating plate 6 so that it is located at the origin of the reclaiming mechanism 2;

[0033] The reclaiming mechanism 2 includes a transverse sliding table 21 and a reclaiming slider 22 mounted on it. A reclaiming frame 24 is installed on the reclaiming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com