Semi-active Laser Air-to-Surface Missile Test Simulation System

A simulation system and missile technology, applied to self-propelled missiles, projectiles, offensive equipment, etc., can solve the problems of inconvenient operation in the field, inconsistent equipment fixtures, and inconsistent data reports, etc., and achieve the effect of facilitating transportation and field operations

Active Publication Date: 2013-10-02

CHINA ACAD OF AEROSPACE AERODYNAMICS

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

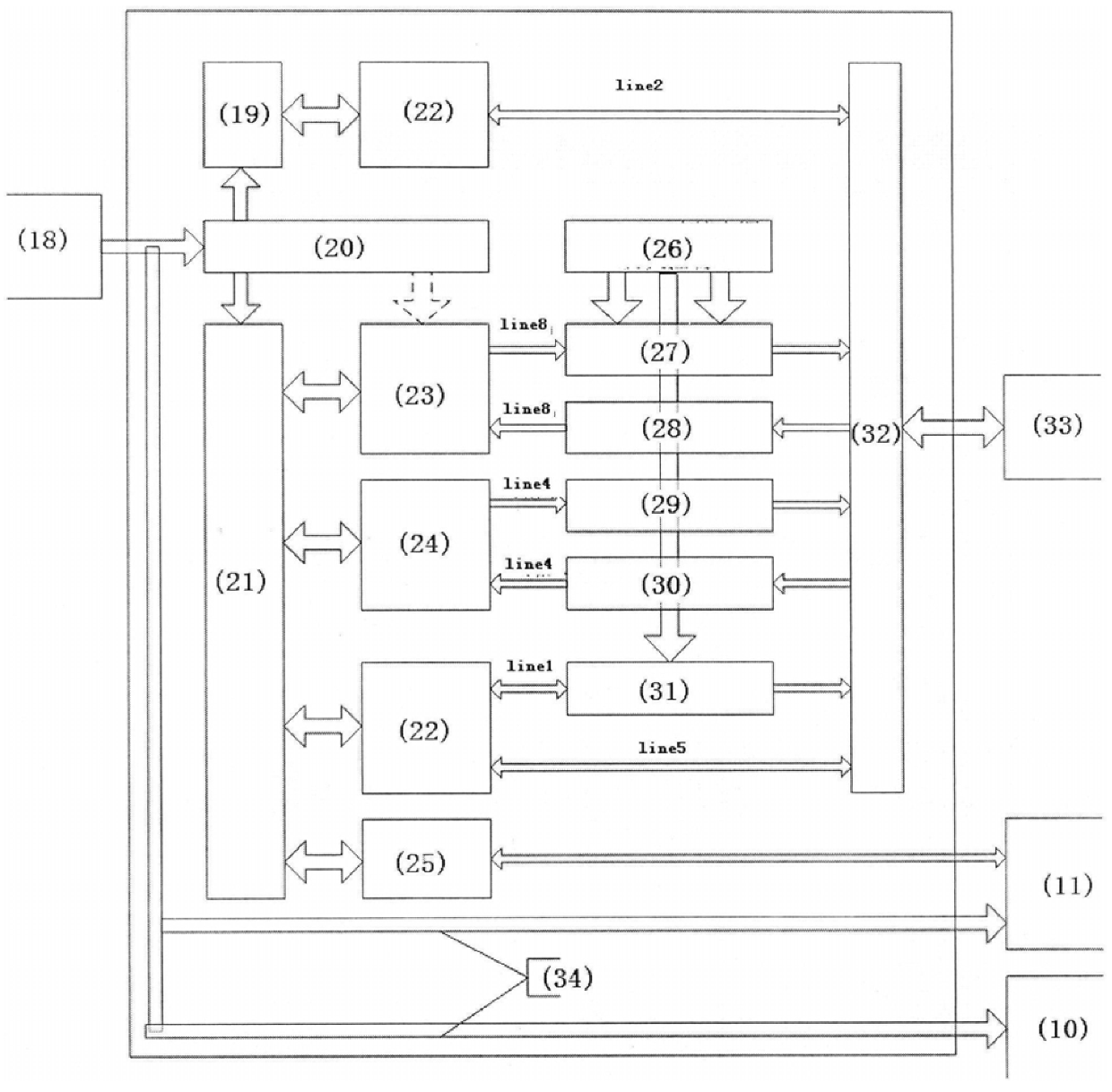

[0040] In Fig. 4, the test simulation system needs to supply power for each system under test during the test. Power supply types include:

[0041]

[0048] Test command display area: during the test process, the test task object sends the command sent in the test to the partition.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

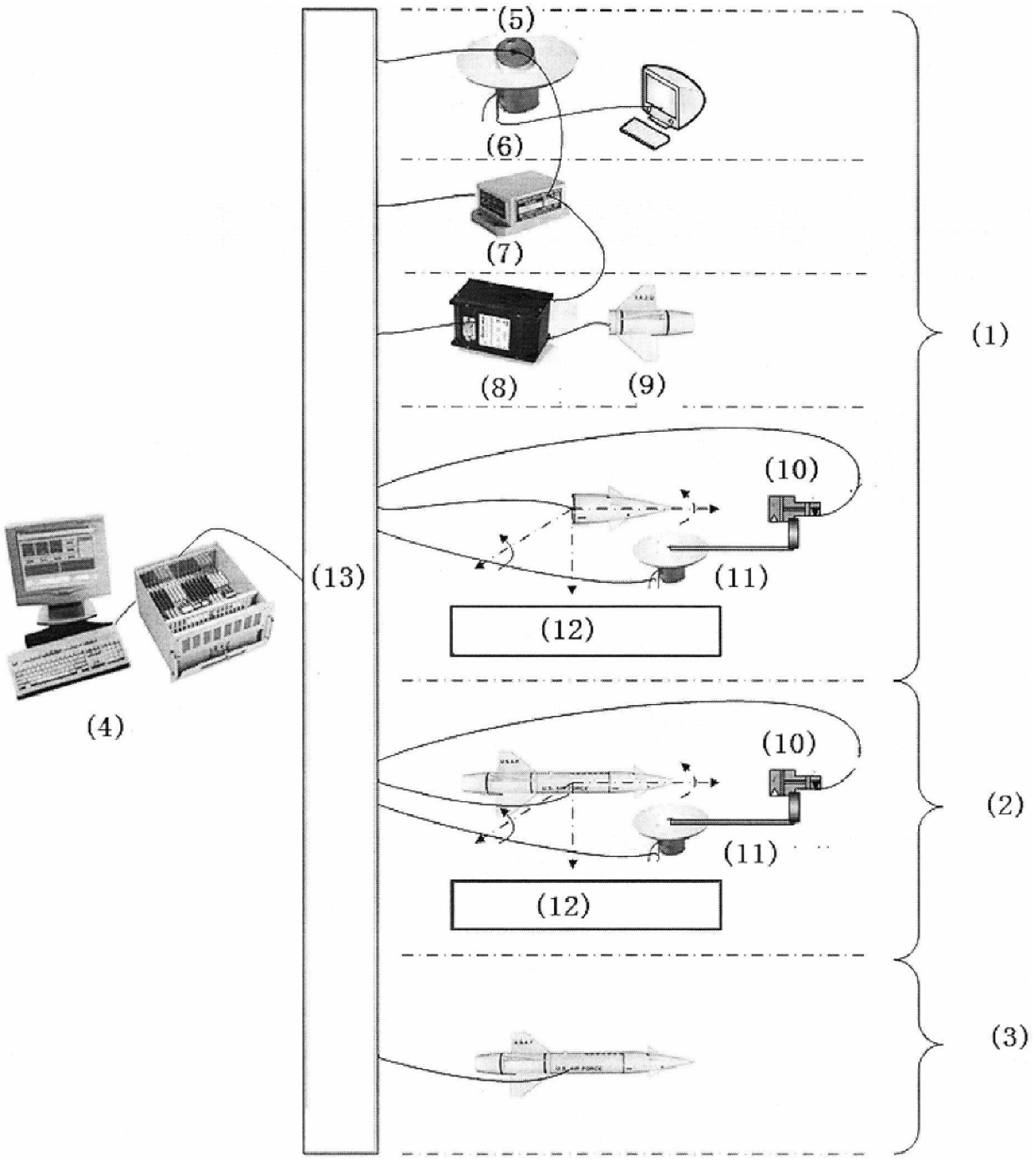

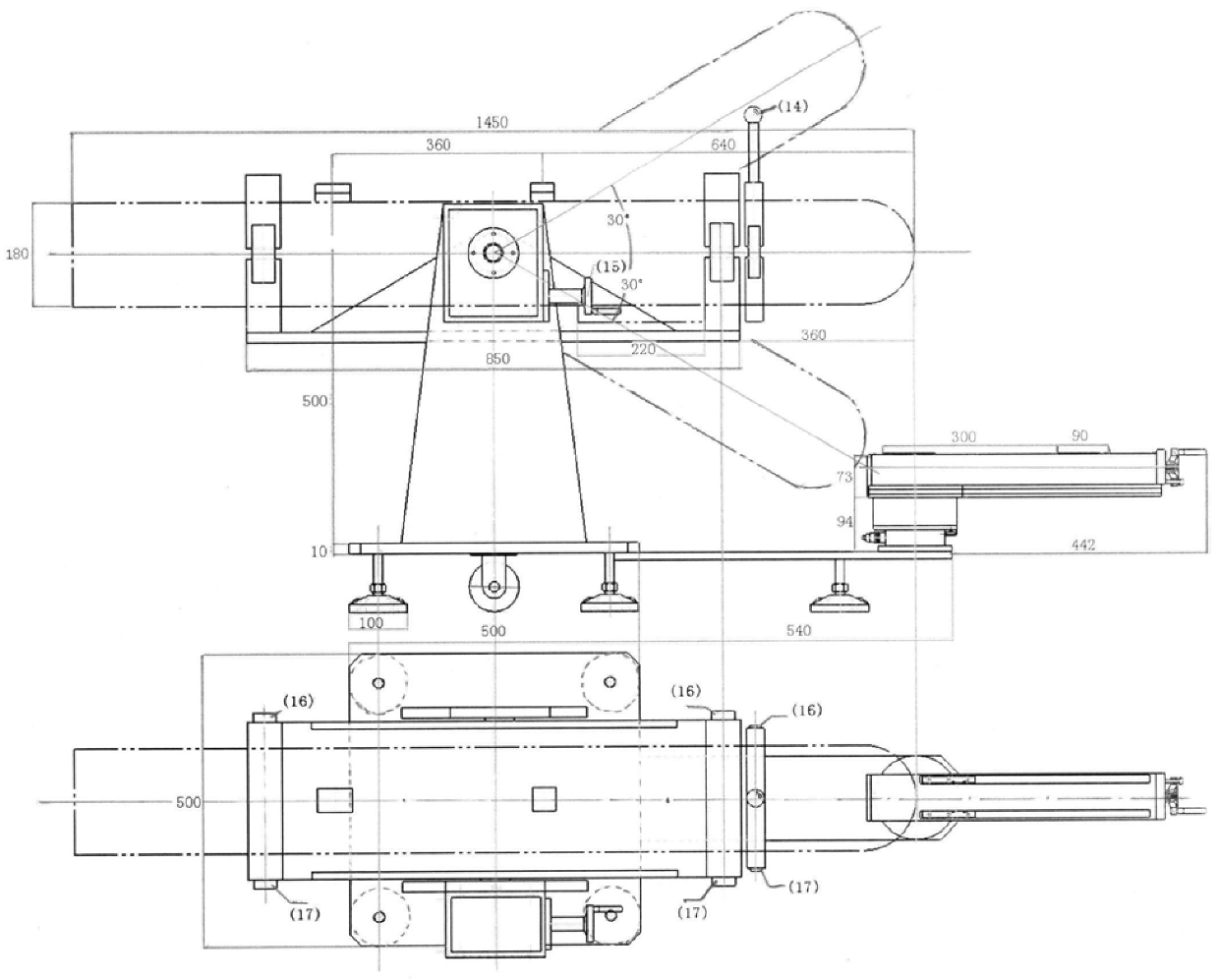

The invention relates to a missile comprehensive test simulation system, which can carry out pre-installation test, post-installation test and flight simulation for semi-active laser air-to-ground missiles and missile-borne equipment, so as to check the coordination and correctness of the work of the whole missile and missile systems. It is characterized in that it includes two parts: a computer part and an electromechanical part, and the computer part includes four parts: a test machine, a simulator, a board card and a power supply unit; the electromechanical part includes a missile supporting mechanism, a target moving mechanism, a turntable and a laser target simulator and other auxiliary equipment. The system has the function of automatic batch test, the test items are optional, the format of the test data is unified and standardized, and the curve can be dynamically displayed along with the test process. The system is an independent box structure, and the missile support mechanism and target movement mechanism can be disassembled, which is convenient for transportation and field operation.

Description

Semi-active laser air-to-ground missile test simulation system Technical field The utility model relates to a kind of automatic comprehensive test emulation system, can semi-active laser air-to-ground missile and projectile Carried equipment for automated testing and flight simulation. Background technique Missile-borne equipment all will pass through a large amount of test inspection work before installation and after installation, after missile is all installed It is also necessary to conduct a joint bomb test to verify the reliability of the equipment workflow. Commonly used test methods are for different devices and Write test software for different test requirements, but because the test principles and hardware interfaces of the sub-equipment are different, the power supply requirements It is also different, so every time a device is tested, it is necessary to write a test software separately, and manually replace different power supplies and test circuits. Cab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F42B15/00

Inventor 张晶莹李刚郝治国吴东伟

Owner CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com