Unloading device for precision filter

A technology of unloading device and filter, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems of large volume, poor reliability, high cost, reduce operating costs, operate stably, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

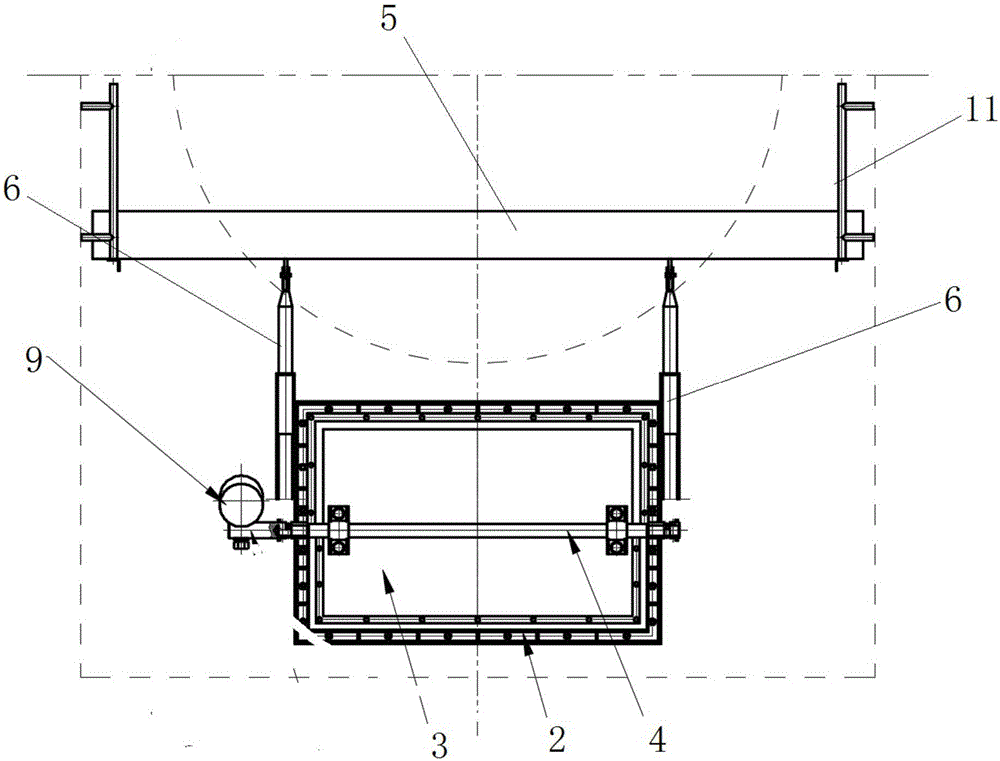

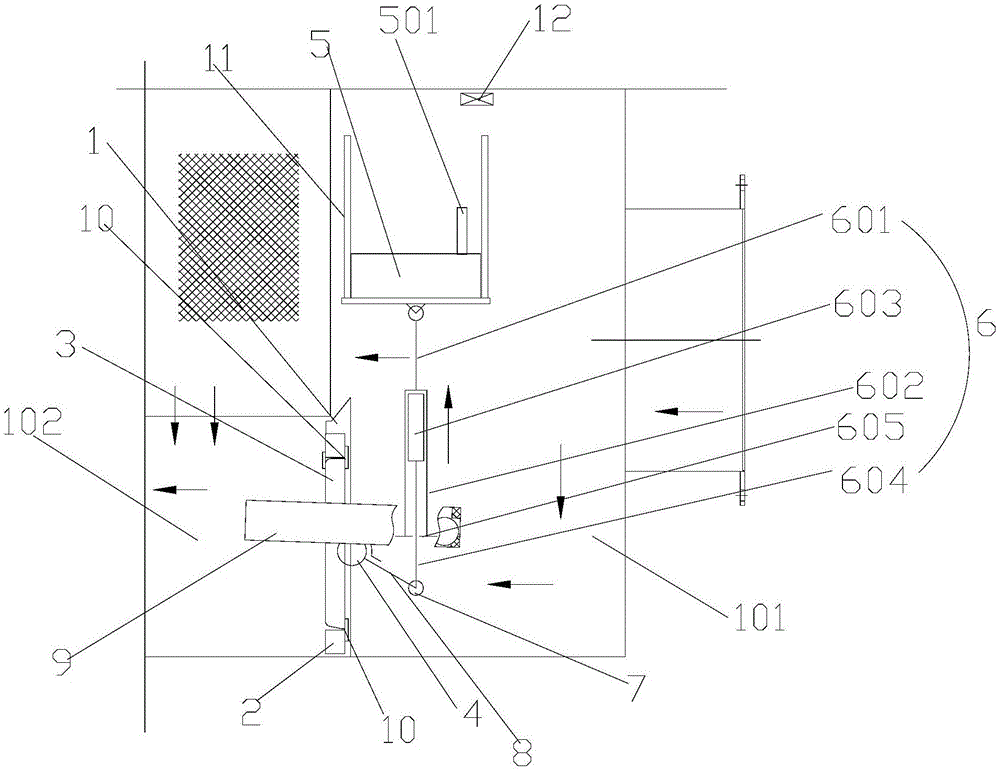

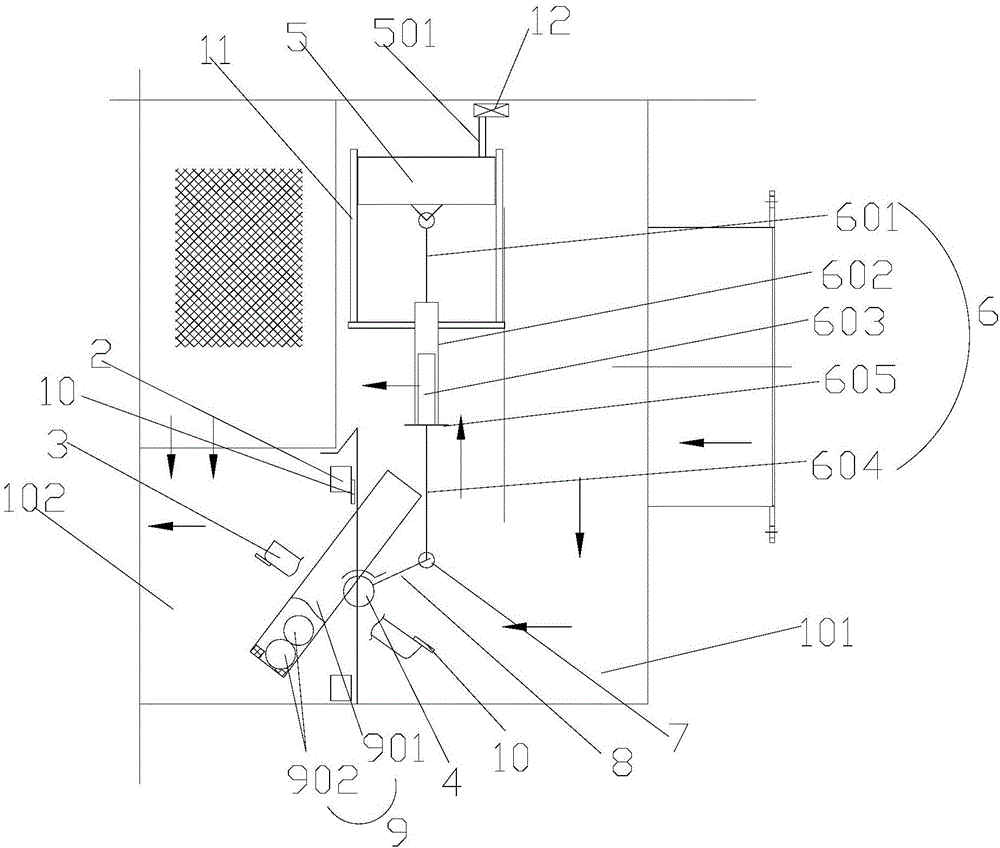

[0023] Examples such as Figures 1 to 3 As shown, a precision filter unloading device includes an inlet and outlet water chamber partition 1 arranged in the filter, and a water inlet chamber 101 and an outlet water chamber 102 respectively arranged on both sides of the inlet and outlet water chamber partition 1 . The door frame 2 is sealed and fixed on the partition plate 1 of the inlet and outlet water chamber, and the door body 3 that can be turned over is arranged in the door frame 2. The door shaft 4 is fixedly installed on the door body 3, and the two ends of the door shaft 4 are installed through bearings. On the inlet and outlet water separator 1, the bearing adopts self-lubricating ceramic rolling bearing. The door shaft 4 drives the door body 3 to rotate to realize the opening and closing of the door body 3 .

[0024] A buoyancy tank 5 is placed in the water inlet chamber 101 of the filter, and a connection assembly is arranged between the buoyancy tank 5 and the doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com