Maintenance apparatus for a shock absorber of a landing gear, and method for maintaining such a shock absorber

A technology for maintaining equipment and shock absorbers, applied in landing gear, aircraft maintenance, transportation and packaging, etc., can solve the problems of inability to automate, expensive installation, free piston is not frictionless, etc., to achieve cycle time maintenance, short cycle The effect of time maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

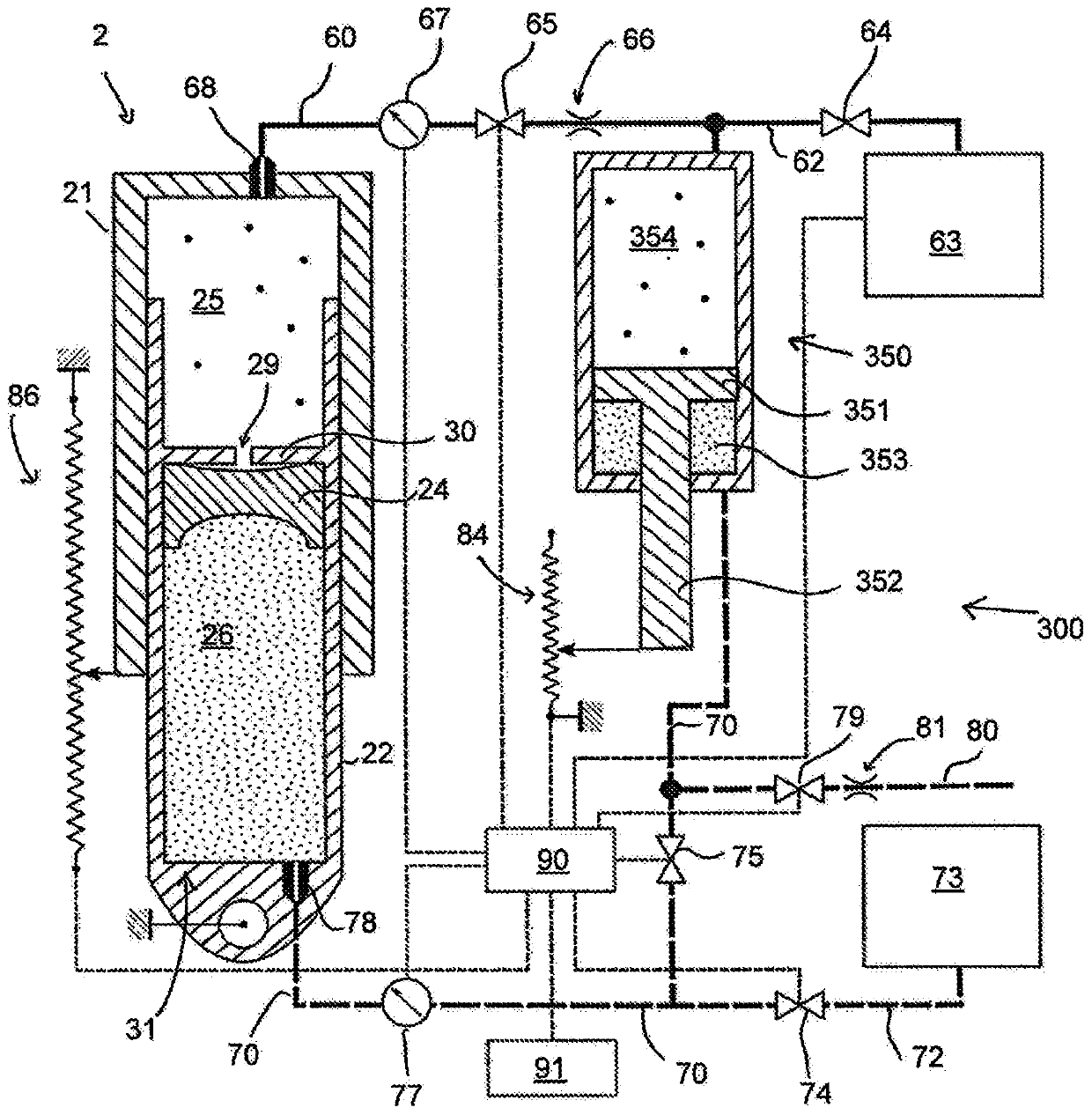

[0100] exist Figure 1 to Figure 4 In , the liquid line is represented by a continuous line. Gas lines are indicated by thick dashed lines. Electrical connections for transmitting electrical signals are indicated by thin dashed lines. The figures are schematic and are intended to illustrate the operation of the maintenance device and method according to the invention. Dimensions and ratios between dimensions do not necessarily correspond to reality.

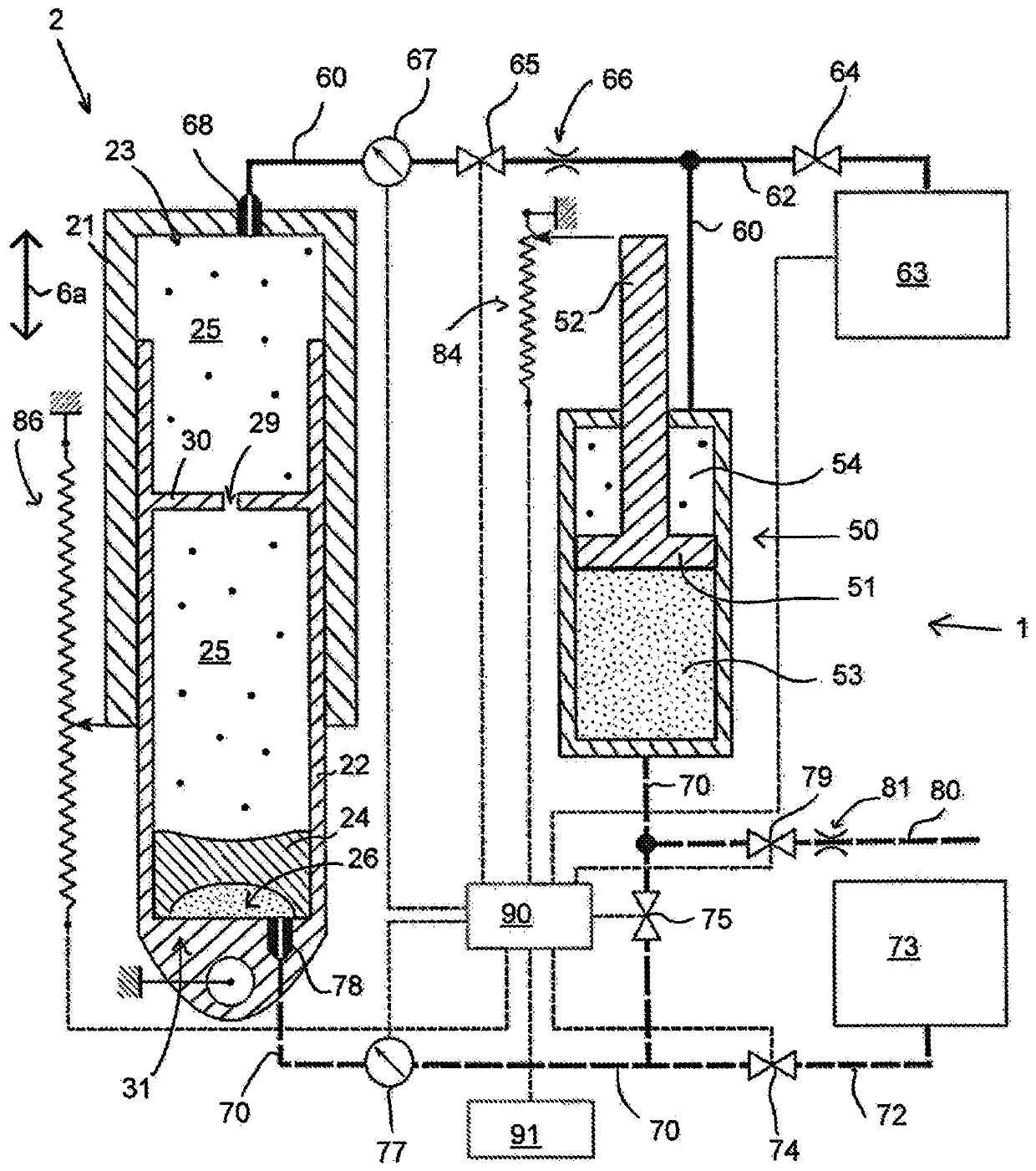

[0101] Figure 5 A maintenance device 1 for servicing a shock absorber 2 of an undercarriage 3 is schematically shown. Maintenance is understood to mean bringing the partial volumes of the inner space of the variant of the shock absorber described in more detail below, respectively occupied by gas and liquid, to predetermined target levels. The landing gear 3 can be the landing gear of any aircraft 7 such as an airplane or a helicopter (in Figure 5 Highly schematically shown). The undercarriage 3 can be configured to be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com