A jet suction stirring flotation machine

A flotation machine and flotation technology, applied in flotation, solid separation and other directions, can solve the problems of reduced injection efficiency, reduced stirring efficiency, disturbed stirring flow field, etc., to reduce flotation energy loss, reduce frictional energy loss, The effect of avoiding dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

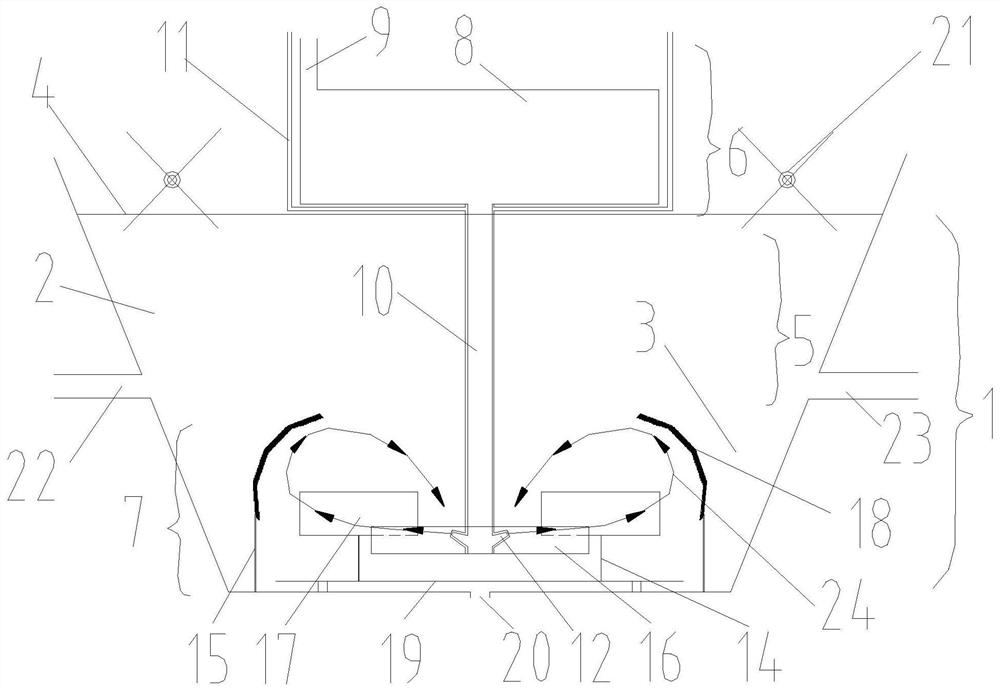

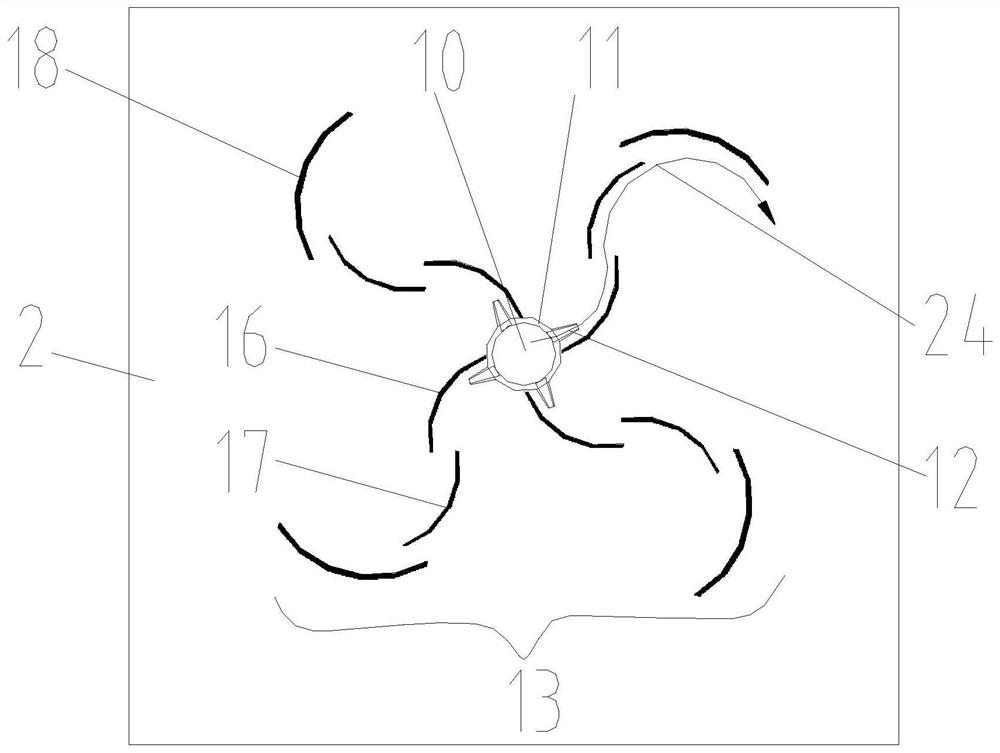

[0018] As shown in the figure, in order to realize above-mentioned purpose, the present invention adopts following technical scheme:

[0019] A jet suction stirring flotation machine comprises a suction mixing mechanism (1), a flotation cell (2), a first support (4), and an ore pulp transport area (5);

[0020] The suction mixing mechanism (1) includes a feeding zone (6) and a stirring and mixing zone (7).

[0021] The feeding area (6) is located on the upper side of the first support (4), and is composed of a mixing bin (8), a circulating feeding port (9), and a suction pipe (10); the mixing bin (8) It is arranged on the upper end of the first support (4) and is used to hold the flotation circulating pulp. The circulating feed inlet (9) is arranged above the mixing bin (8), and the feeding pipe (10) is arranged at the mixing bin (8). The lower end of the silo (8) is communicated with the mixing silo (8);

[0022] The stirring and mixing zone (7) comprises a feeding pipe (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com