Full-automatic clean-in-place machine

A washing machine, fully automatic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as poor reproducibility, large human interference factors, and inaccurate judgment of the cleanliness of objects , achieving the effects of good reproducibility, small human interference factors, and shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

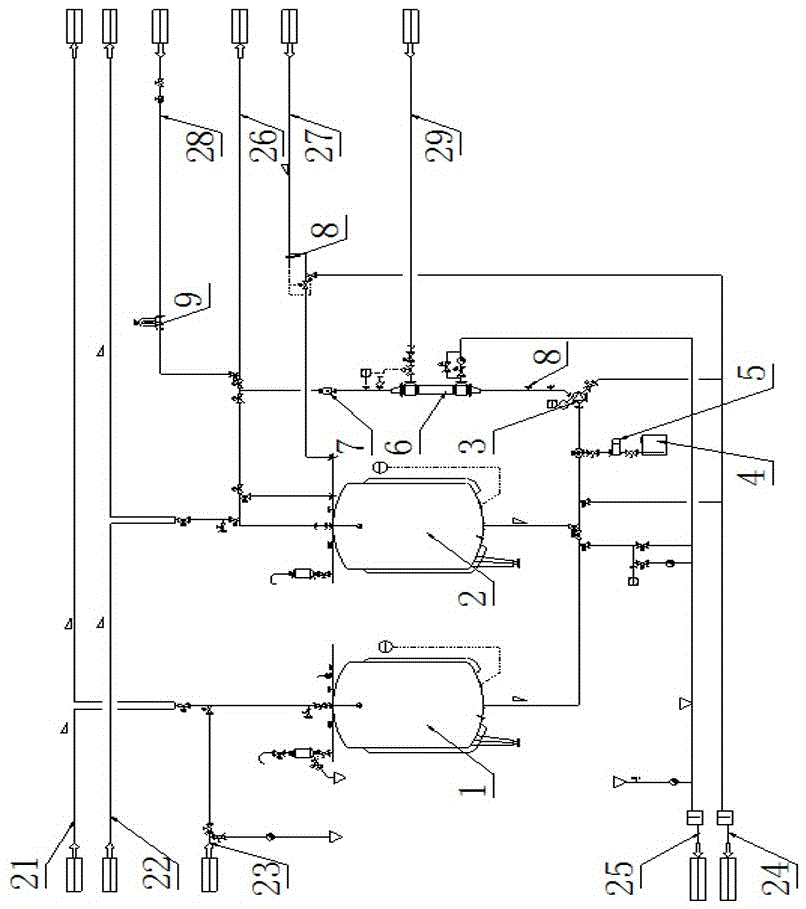

[0017] see figure 1 , a fully automatic online cleaning machine, including a rinsing system, a cleaning system, an alkali cleaning system, an injection system and a purified water system, the rinsing system includes a rinsing tank 1, and the top water inlet of the rinsing tank 1 is connected to the injection The water pipe 21 and the pure steam inlet pipe 23, the bottom water outlet of the rinsing tank 1 is connected to the sanitary centrifugal pump 3 through the liquid supply pipe; the cleaning system includes a cleaning tank 2, the top water inlet of the cleaning tank 2 is connected to the purified water pipeline 22, and The water outlet at the bottom of the tank 2 is connected to the liquid supply pipeline; the alkali washing system includes the lye bucket 4, and the lye bucket 4 is connected to the liquid supply pipeline through the metering pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com