Economical bottom-paper-free high-speed cutting die machining device

A processing device and linerless technology, applied in metal processing and other directions, can solve the problems of shortened blade life, high cost of die, and long development cycle, so as to reduce production costs and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

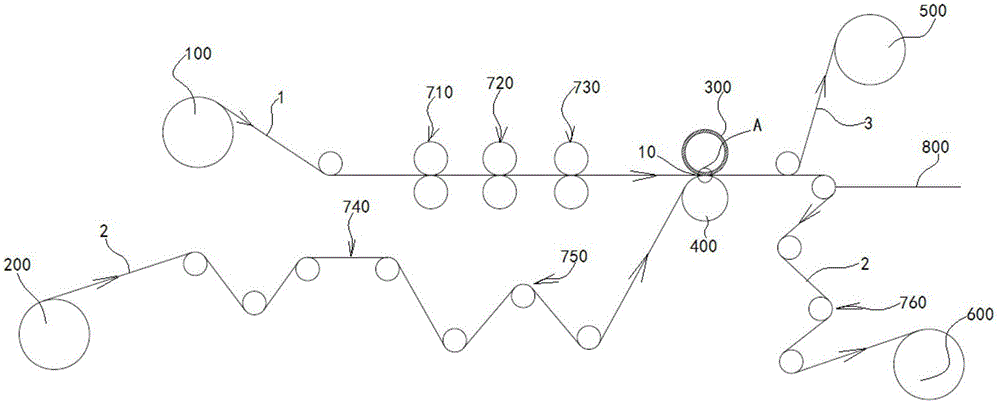

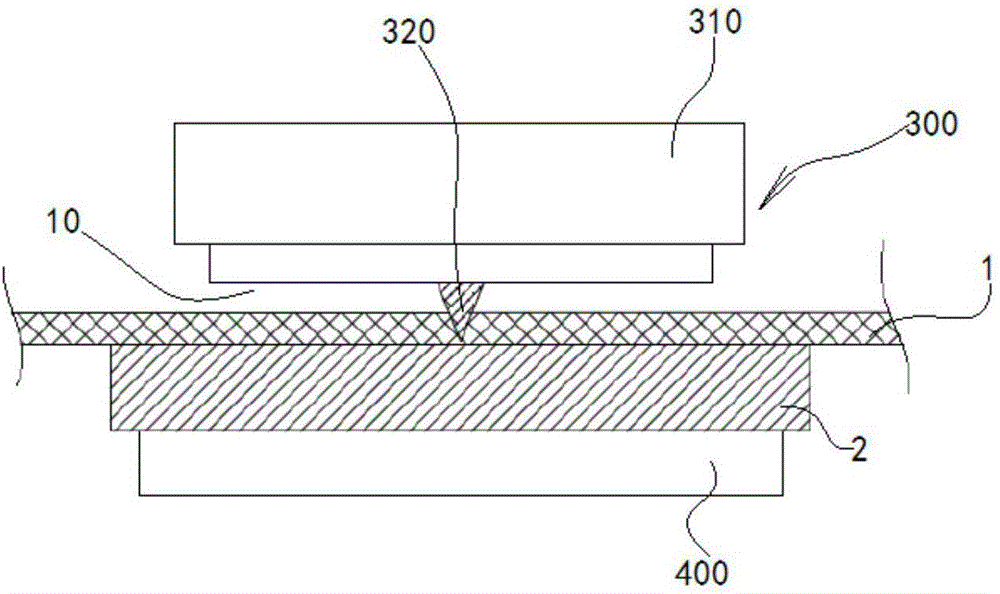

[0027] see figure 1 , shown in the figure is an economical bottomless high-speed die-cutting processing device, including a frame (not shown in the figure), a die-cut material unwinding roller 100, a protective backing paper unwinding roller 200, a die cutter Roll 300 , Die Cut Bottom Roll 400 , Die Cut Waste Rewind Roll 500 , and Protective Backing Paper Rewind Roll 600 .

[0028] Die-cutting material unwinding roller 100 axis is arranged on the frame, and it is used for die-cutting material 1 is released.

[0029] The protection backing paper unwinding roller 200 shaft is arranged on the frame and is positioned under the die-cutting material unwinding roller 100, and it is used for releasing the protection backing paper 2, and in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com