Strength-adjustable wood-plastic walkway plate production mold

An adjustable, plastic mold technology, used in household appliances, other household appliances, applications, etc., can solve the problems of high production costs, inability to change according to needs, limited production scope, etc., to achieve increased production costs and adjustable compressive strength. , The effect of increasing product specifications

Inactive Publication Date: 2017-05-24

HUANGSHI ZHONGJIE MOLD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is: in order to solve the problems existing in the above-mentioned background technology, an improved mold for the production of wood-plastic plank boards with adjustable strength is provided, which solves the problem that the traditional plastic molds for producing wood-plastic boards have a single structure. Unable to adjust, the compressive strength of the wood-plastic plank board cannot be changed according to the needs, resulting in a very limited production range and relatively high production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

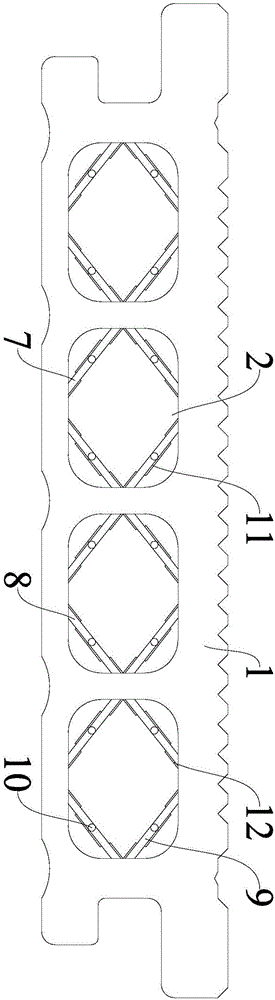

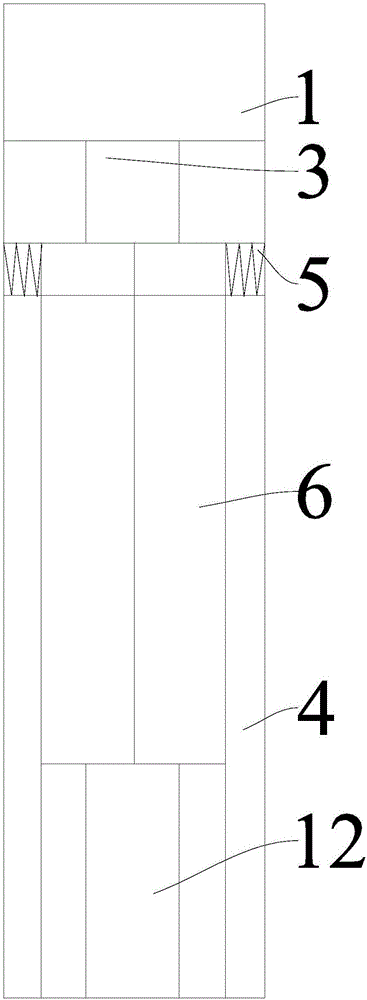

[0017] Embodiment: The plastic mold body 1 is manufactured by a CNC machine tool, the supporting multi-link 7 inside the top mounting groove 3 and the lateral mounting groove 4 is connected to the inner side wall of the lateral mounting groove 4 through the top rotating shaft, and the lateral elastic storage groove 5 A spring for increasing the pressing force on the elastic sealing plate 6 is arranged inside.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of production molds, in particular to a strength-adjustable wood-plastic walkway plate production mold. The strength-adjustable wood-plastic walkway plate production mold comprises a plastic mold body. Four holes with the same size are formed in the plastic mold body, and top corners of the four holes are each of an arc-shaped structure. According to the strength-adjustable wood-plastic walkway plate production mold, top end mounting grooves and lateral mounting grooves communicating with the top end mounting grooves are formed in the inner sides of the holes, multiple supporting rods in the top end mounting grooves are movably connected with the lateral mounting grooves in the two sides correspondingly, the turning angles of the connecting rods are limited through limiting plates and sealing plates on the multiple supporting rods correspondingly, openings of the top end mounting grooves and openings of the lateral mounting grooves are closed through cooperation of the limiting plate, the sealing plates and elastic sealing plates, and thus internal airtightness is greatly improved; and in addition, the structure and surface compressive strength of the whole plastic mold can be adjusted, the mold is suitable for products of more specifications, and production cost is reduced.

Description

technical field [0001] The invention relates to the technical field of production moulds, in particular to a strength-adjustable mold for the production of wood-plastic plank boards. Background technique [0002] Wood-plastic composite material is an emerging manufacturing material, which is mainly used to replace traditional building materials in the building decoration industry. The traditional plank boards used in construction are weak in fireproof, waterproof and termite-proof, and cannot be recycled. The plastic mold structure of the plank board is single and cannot be adjusted, so the compressive strength of the wood-plastic plank board cannot be changed according to the needs, resulting in a very limited production range and relatively high production costs. Contents of the invention [0003] The technical problem to be solved by the present invention is: in order to solve the problems in the above-mentioned background technology, provide an improved mold for the p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C33/00B29L31/10

CPCB29C33/00B29L2031/10

Inventor 朱积平

Owner HUANGSHI ZHONGJIE MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com