A breathing bag production device

A technology for a production device and a breathing bag, which is applied in the field of breathing bag production devices, can solve problems such as the inability to realize continuous cutting of the breathing bag, complicated steps in the processing of the breathing bag, and the impact on the production efficiency of the breathing bag, and achieve simple structure, low cost, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

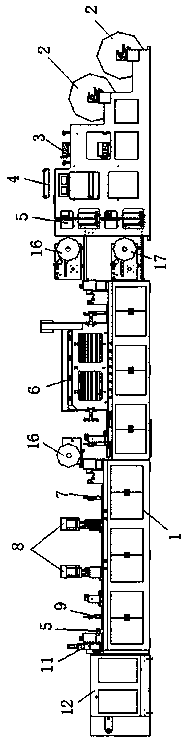

[0024] It can be seen from the accompanying drawings that a breathing bag production device includes a chassis 1, on which a raw material winding device 2, a dust removal and static electricity removal device 3, a guide frame 4, a traction device 5, a first One ironing knife mechanism 6, traction device 5, two second ironing knife mechanisms 8, photoelectric tracking device 9, traction device 5, cutting device 11 and receiving table 12.

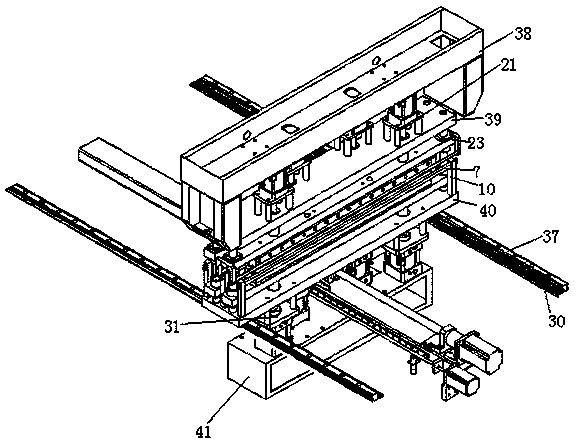

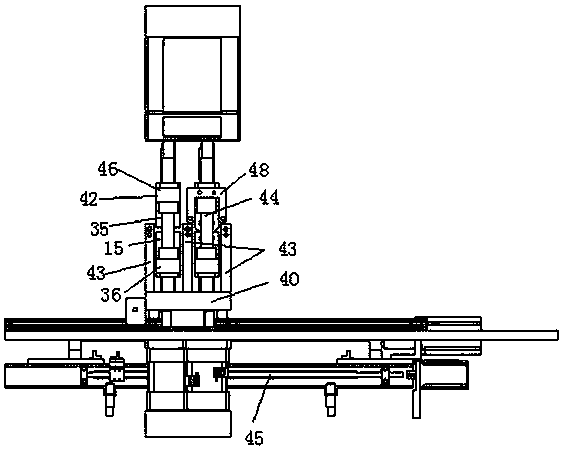

[0025] The first ironing knife mechanism 6 includes two first frames 13, a first ironing knife device, an ironing knife shell 14 and an ironing cloth rewinding device, and the two first frames 13 are arranged on the cabinet 1 in parallel, The first frame 13 is provided with a slide rail, the first ironing knife device is arranged in parallel on the first frame 13, and the lower end of the first ironing knife d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com