Structure improved transport vehicle

A technology of structural improvement and transport vehicles, which is applied in the field of transportation tools, can solve the problems that workers cannot load or unload goods alone and the operator is inconvenient, and achieve the effects of improving work enthusiasm, reducing labor intensity, and expanding production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

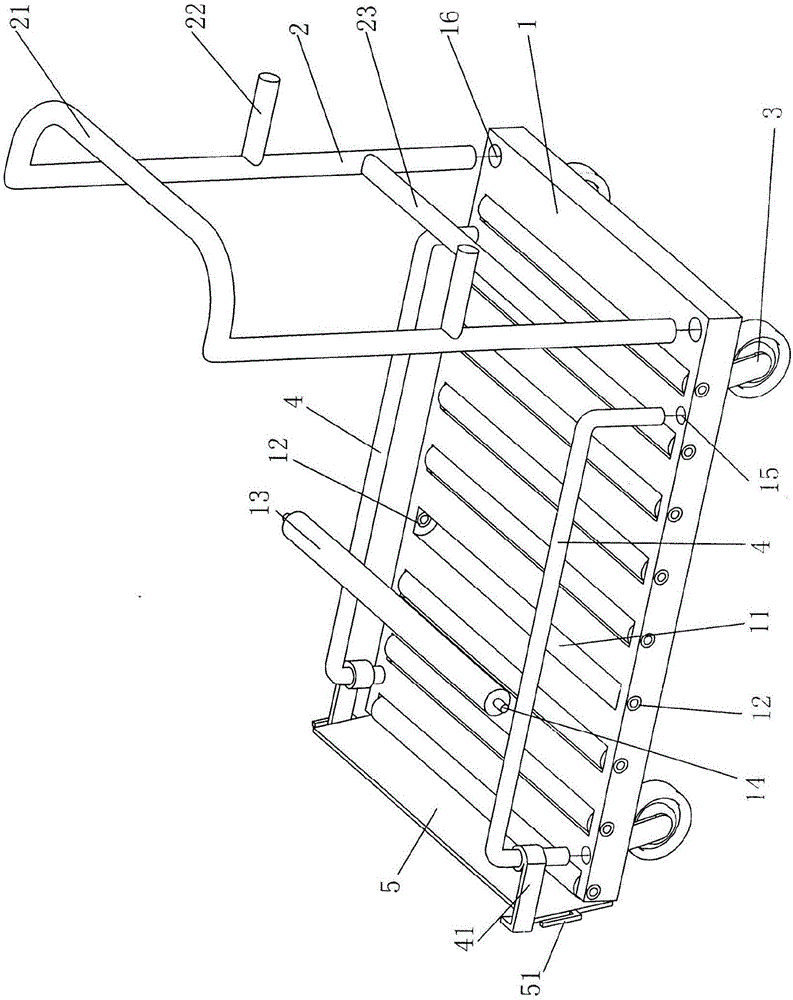

[0016] see figure 1 , the present invention relates to a transport vehicle with improved structure, comprising a base 1, a support rod 2 and wheels 3, the support rod 2 is connected through a pair of support rod insertion holes 16 arranged on both sides of one end of the base 1 in the lengthwise direction. Fixed on the upper plane of the base 1, a wheel 3 is respectively fixed at the four corners of the bottom surface of the base 1. It is characterized in that: the base 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com