Single saucer wing flying saucer

A flying saucer and single saucer technology, applied in the field of aircraft, can solve the problems of reducing overall weight and disadvantages, and achieve the effect of light overall weight, large room for maneuver, and simple and easy-to-manufacture overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

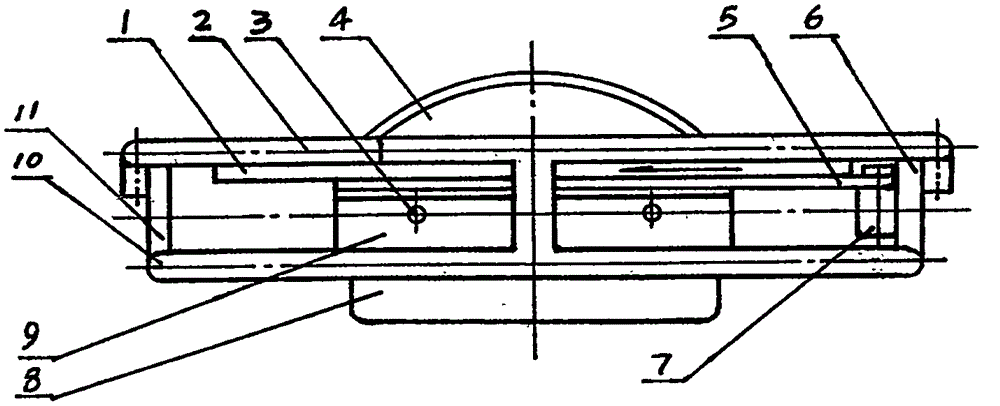

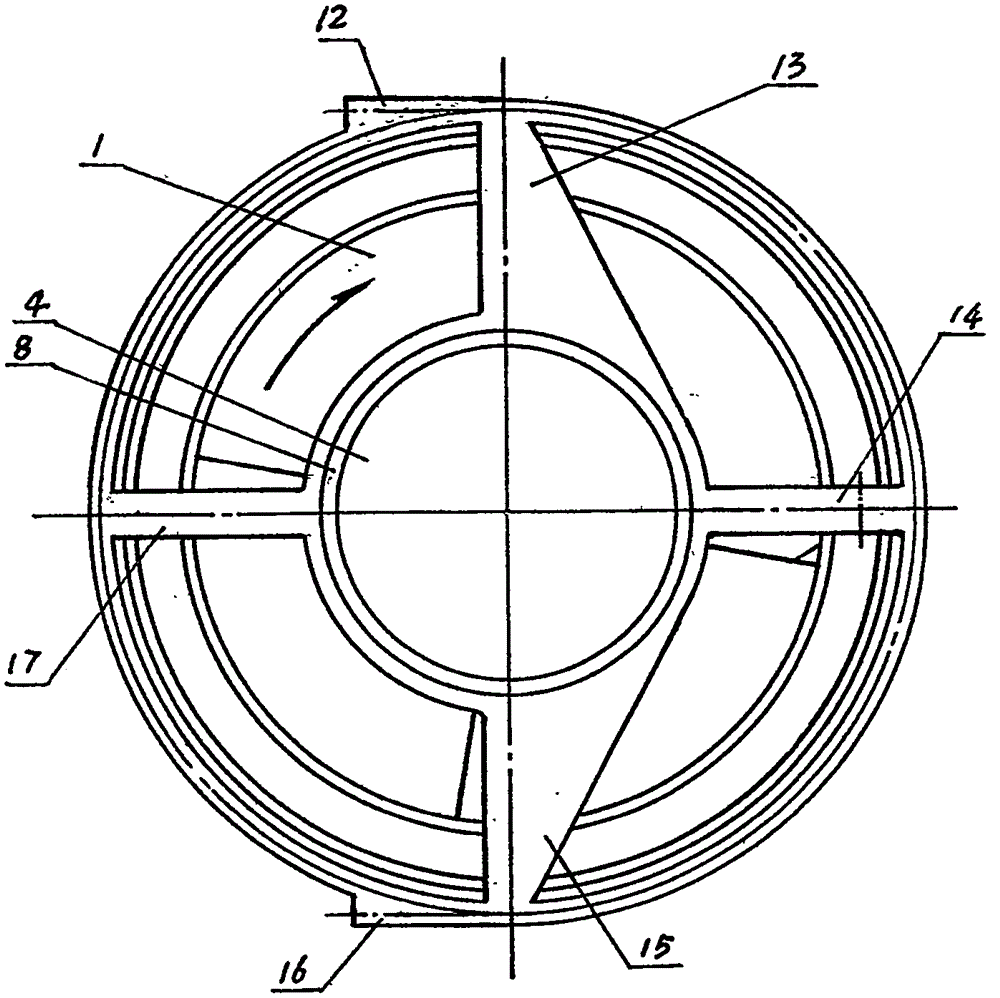

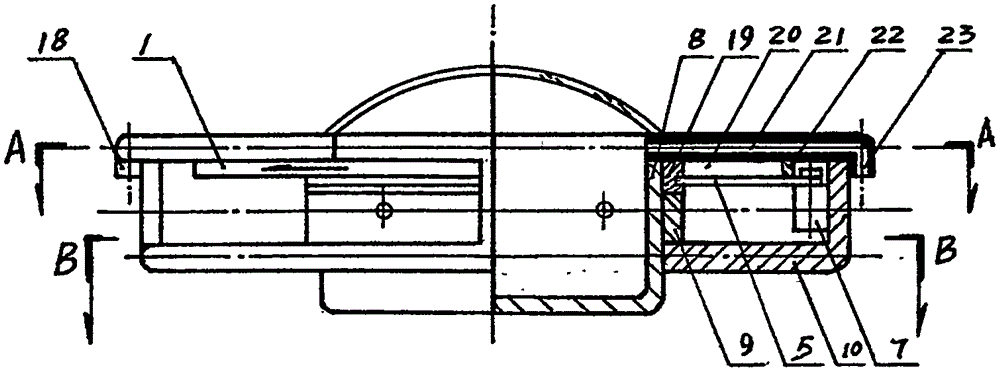

[0024] In the picture:

[0025] 1. Disc fin, 2. Upper protective ring, 3. Bolt, 4. Transparent disc hatch cover, 5. Belt, 6. Front vertical strut, 7. Motor, 8. Disc cabin body, 9. Limiting ring, 10, the lower protective ring, 11, the rear vertical strut, 12, the left air nozzle, 13, the upper left horizontal strut, 14, the front upper horizontal strut, 15, the right upper horizontal strut, 16, the right air nozzle, 17, Rear upper transverse strut, 18. Rear air nozzle, 19. Inner yoke ring, 20. Disc wing blade, 21. Air pipe, 22. Outer yoke ring, 23. Front air nozzle, 24. Interval hole, 25. Driven gear , 26, belt groove, 27, elevation angle, 28, anti-torque air nozzle, 29, left solenoid valve, 31, front solenoid valve, 32, right solenoid valve, 33, rear solenoid valve, 34, air supply mechanism.

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , Figure 6 , the front vertical strut 6 and the rear vertical strut 11 are jointly connected with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com