Secondary flow self-circulation pneumatic adjustable inlet port and control method of same-stage compression surface

A compression surface and air inlet technology, which is applied to the combustion of the air inlet of the power unit, the power unit on the aircraft, the arrangement/installation of the power unit, etc., can solve the problems of limitation and occupying valuable space of the aircraft, and achieve a small footprint , avoid sealing/heat protection problems, and improve the effect of flow coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

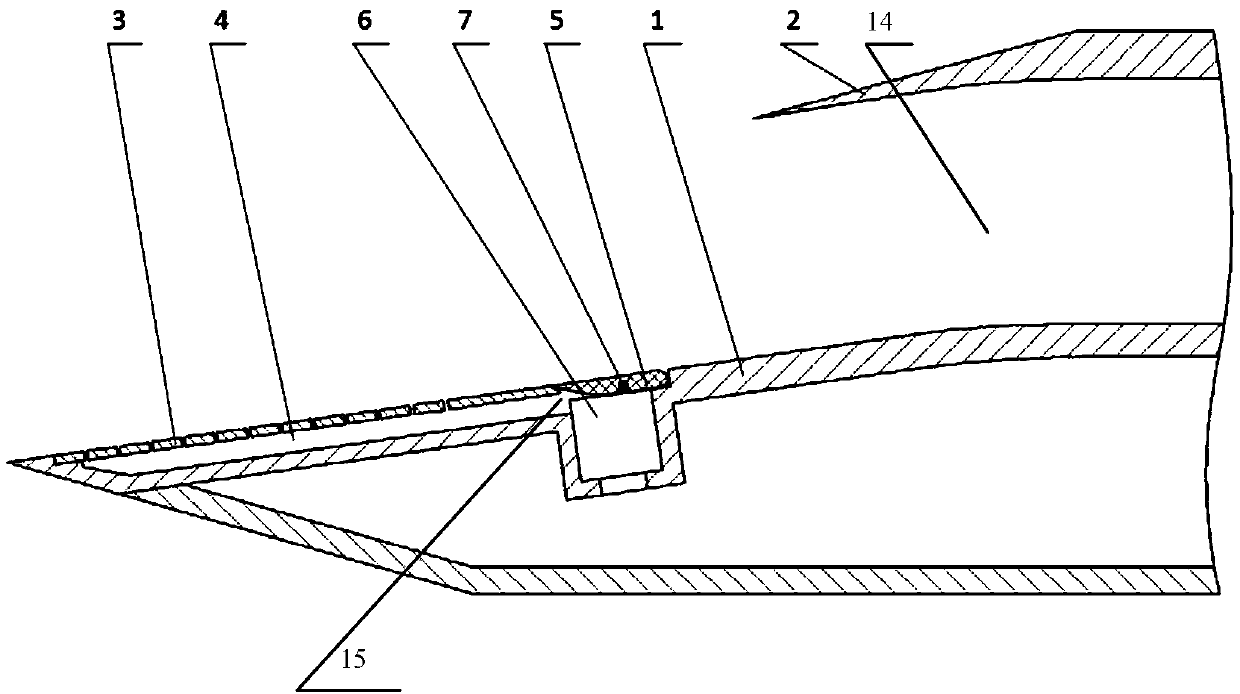

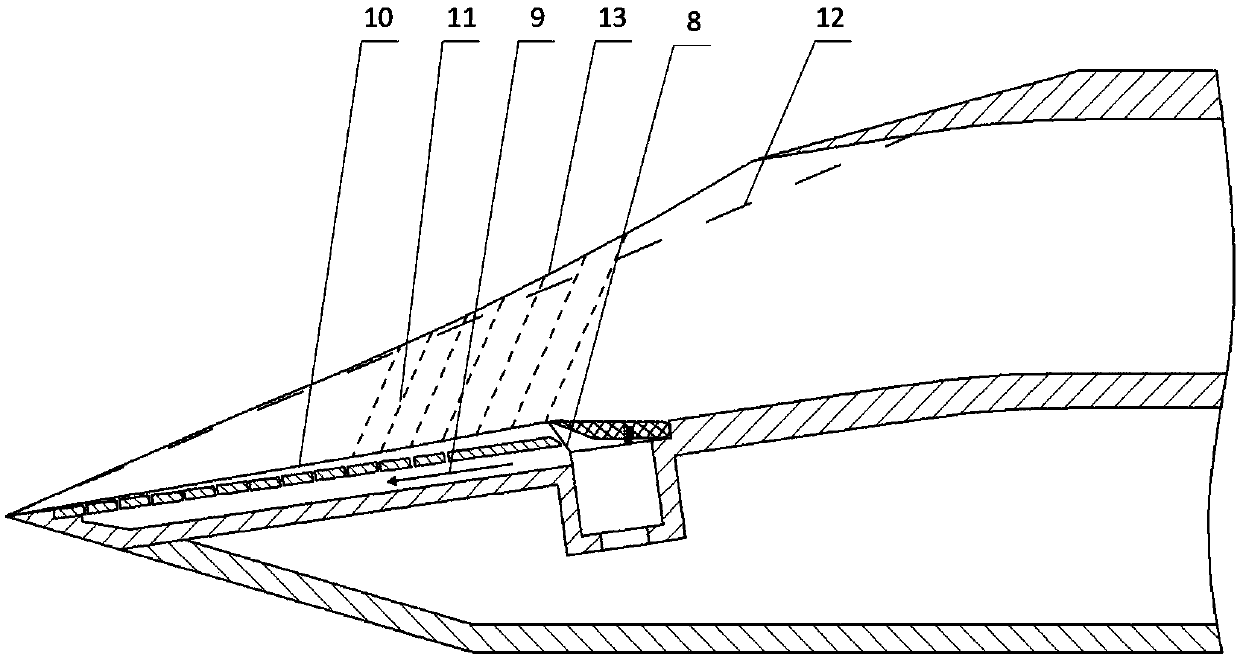

[0016] see figure 1 and figure 2 As shown, the present invention discloses a secondary flow self-circulating pneumatic adjustable air inlet of the same stage compression surface, which is mainly used in the design and manufacture of supersonic / hypersonic air inlets. The precursor of this type of air inlet is composed of at least one section of inclined plane, and the gas flow is compressed by the shock wave of the precursor outside the air inlet. The same-stage compression surface secondary flow self-circulation pneumatic adjustable air inlet includes the air inlet compression surface 1, the air inlet lip cover 2 located outside the air inlet compression surface 1, and the air inlet lip cover 2 covering the air inlet compression surface 1. The overflow cover plate 3 at the top, the pressure stabilizing chamber 4 located below the overflow cover plate 3, the rotating cover plate 5 installed on the compression surface and located at the rear end of the overflow cover plate. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com