Deoxidation process for H08 steel-grade silicon

A technology of steel grade and process, applied in the field of H08 steel grade silicon deoxidation process, can solve the problems of high price of aluminum deoxidizer, blocked flocculation at the nozzle, low cleanliness of molten steel, etc., to reduce the difficulty of removing inclusions, reduce alloy costs, The effect of improving the purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

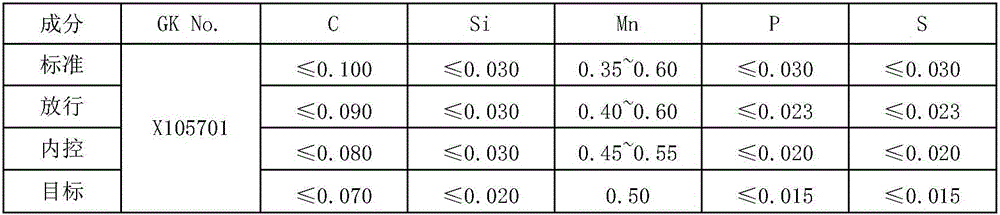

[0018] (1) The molten steel composition is designed as follows:

[0019]

[0020] ①This series of steel grades is based on the carbon content range requirements of different steel grades. The oxygen content of the steel at the end of the converter is ≥ 500ppm, and the temperature at the end is controlled at 1650°C as much as possible. Keep the end point temperature, and there is serious peroxidation phenomenon in molten steel;

[0021] ② No other deoxidizers and alloys are added during the tapping process of the converter;

[0022] ③ During the tapping process, ferrosilicon is added for pre-deoxidation, and the reference dosage is 18kg deoxidation 100ppm (Note: 150t molten steel);

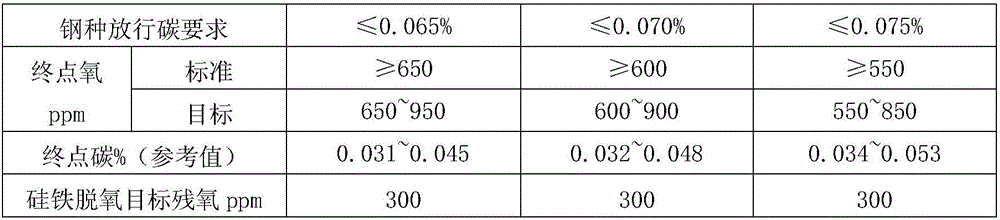

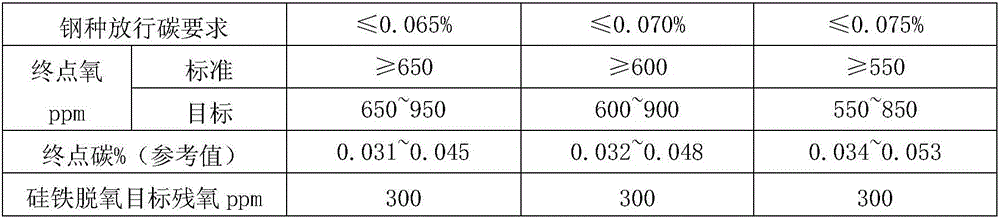

[0023] ④According to the target oxygen requirements of different GK steel types, use ferrosilicon to deoxidize to the target range, refer to the following:

[0024]

[0025] ⑤The argon station or LF furnace is used for deoxidation and alloying again, and the target oxygen and composition ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com