A pulsed laser-assisted chemical vapor deposition growth system device and a method for preparing low-dimensional materials using it

A technology of chemical vapor deposition and pulsed laser deposition, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor quality, limited growth of high melting point materials, and failure to reach, etc., to achieve Effect of avoiding impurity introduction, improving growth efficiency and material type, overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

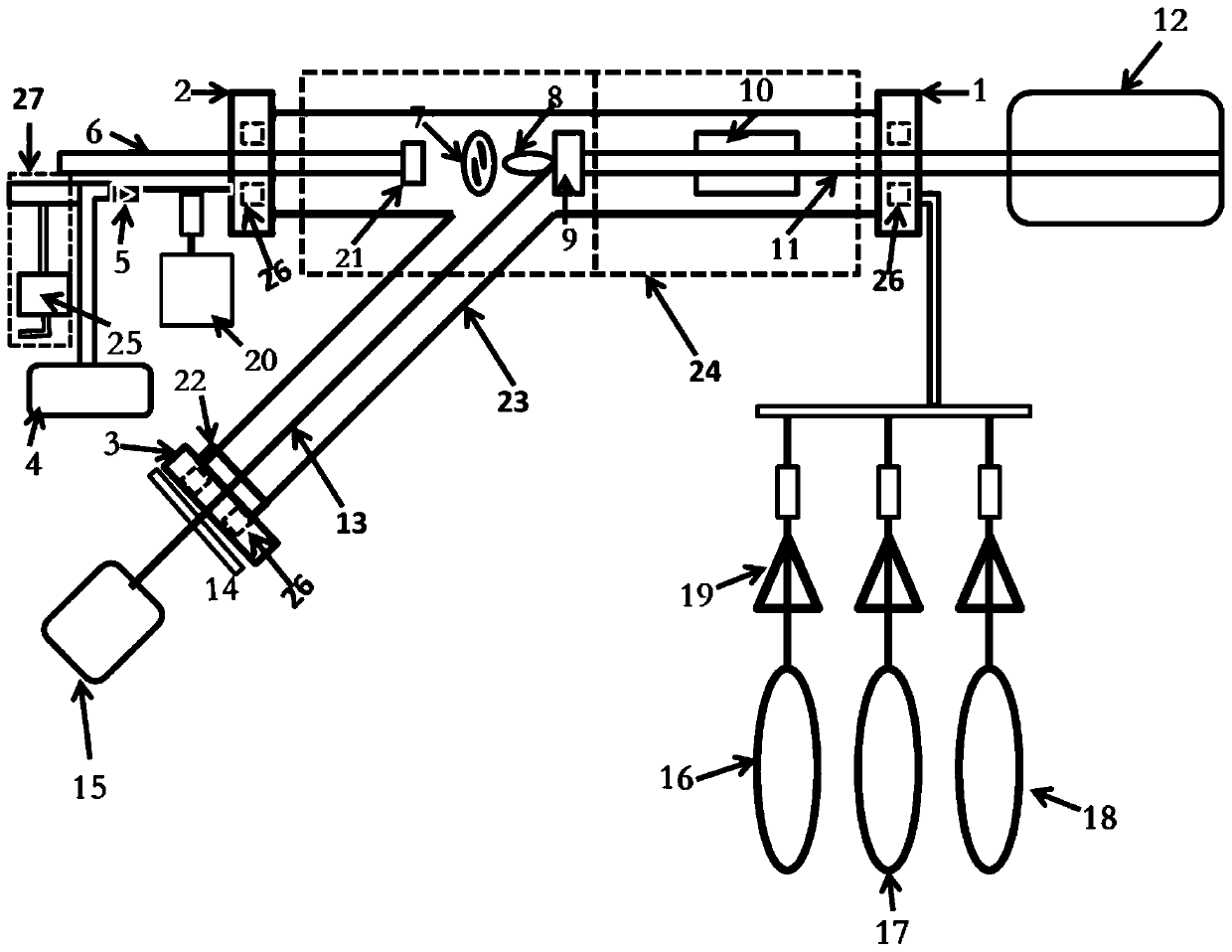

[0061] A pulsed laser assisted chemical vapor deposition growth system device, its structure schematic diagram is as follows figure 1 As shown, the meanings of the numbers in the figure are:

[0062] 1-first flange, 2-second flange, 3-third flange, 4-vacuum system, 5-vacuum system valve, 6-magnetic transmission rod, 7-high temperature resistant sample holder, 8-plasma plume Hui, 9-high temperature resistant target holder, 10-material boat, 11-high temperature resistant target rod, 12-motor, 13-laser beam, 14-focusing mirror, 15-pulse laser, 16-carrier gas 1, 17- Carrier gas 2, 18-carrier gas 3, 19-flow control meter, 20-vacuum gauge, 21-high temperature resistant substrate baffle, 22-laser baffle, 23-Y tube, 24-double temperature zone tube furnace , 25-exhaust gas purification device, 26-cooling system, 27-exhaust system.

[0063] This system device comprises pulsed laser (15), heating system, growth chamber, vacuum system (4), cooling system (26), carrier gas system and exh...

Embodiment 2

[0071] Using the system device of the present invention to prepare La by pulsed laser deposition 0.5 Sr 0.5 MnO 3 (LSMO) epitaxial thin film

[0072] The substrate material can choose lanthanum aluminate LaAlO 3 (LAO), you can also choose strontium titanate SrTiO 3 (STO), etc., as long as it meets the requirements of film growth, it can be used as the substrate material of the present invention to grow epitaxial films.

[0073] In this embodiment, choose LaAlO 3 As a substrate material, its crystal orientation is (001).

[0074] For substrate materials, pretreatment is required. In this example, LaAlO 3 For the substrate, the pretreatment step included ultrasonic cleaning with trichlorethylene for 7 min, followed by acetone for 5 min, alcohol for 1 min, and blowing with an air gun.

[0075] In this example, choose to prepare La 1-x Sr x MnO 3 , x=0.5.

[0076] For the target material, first grind it on coarse sandpaper, then grind it on fine sandpaper, then clean i...

Embodiment 3

[0091] Preparation of ZnO nanowires by chemical vapor deposition using the system device of the present invention

[0092] Put 20 grams of 99.99% pure ZnO powder on the center of the material boat, and adjust the position of the material boat to the center of the temperature zone.

[0093] Take a 10mm*10mm gold-plated silicon substrate, and ultrasonically wash the substrate with trichlorethylene, acetone and absolute ethanol respectively, each time for about 5 minutes, blow dry with a nitrogen gun, and place the cleaned substrate on a distance material 5cm from the boat (on the downstream side of the carrier gas).

[0094] The growth chamber was sealed and evacuated by the vacuum system to 10 -4 Pa, set the temperature program of the instrument, and rise to 1100°C in 110 minutes.

[0095] Open the oxygen valve, feed oxygen at a rate of 14mcc, oxygen pressure of 20Pa, growth time of 40min, close the oxygen valve, keep the oxygen pressure of the growth chamber at 20Pa, and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com