A kind of sapphire crystal growth equipment

A sapphire crystal and equipment technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor effect, can not meet the preparation of high-quality sapphire crystal, reduce thermal stress, prevent crystal melting, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

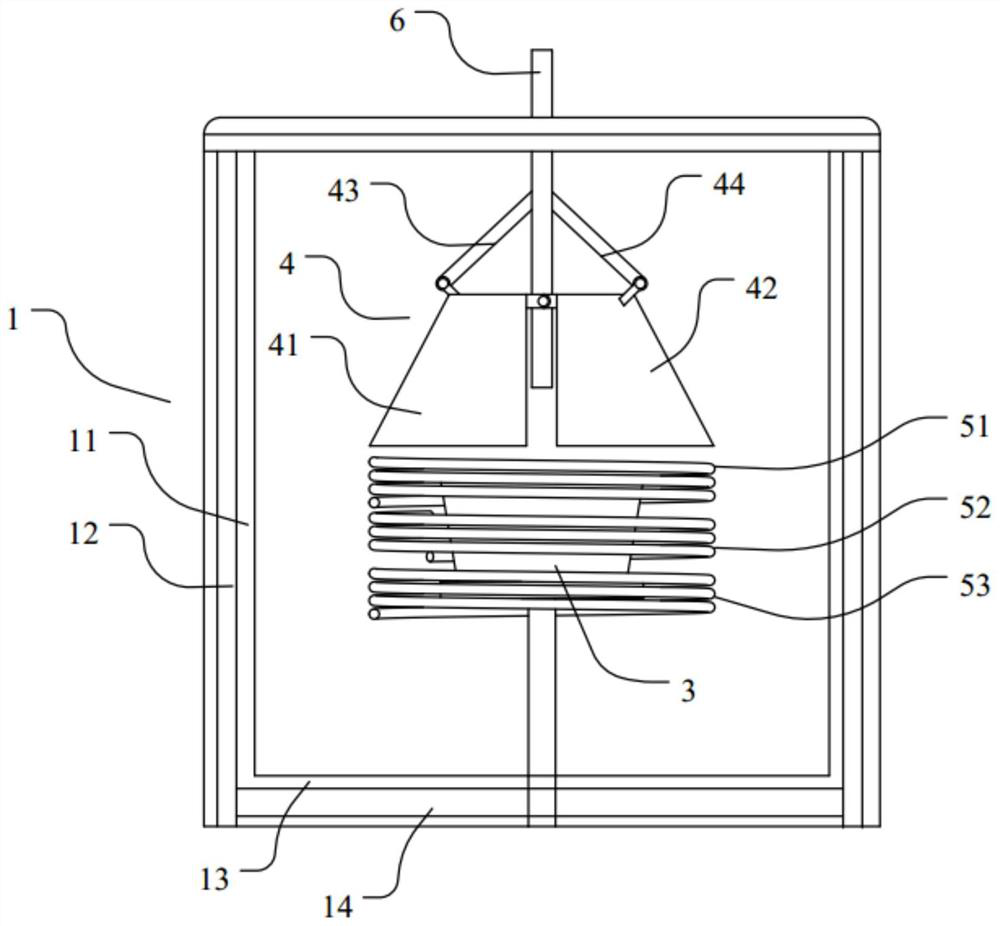

[0025] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

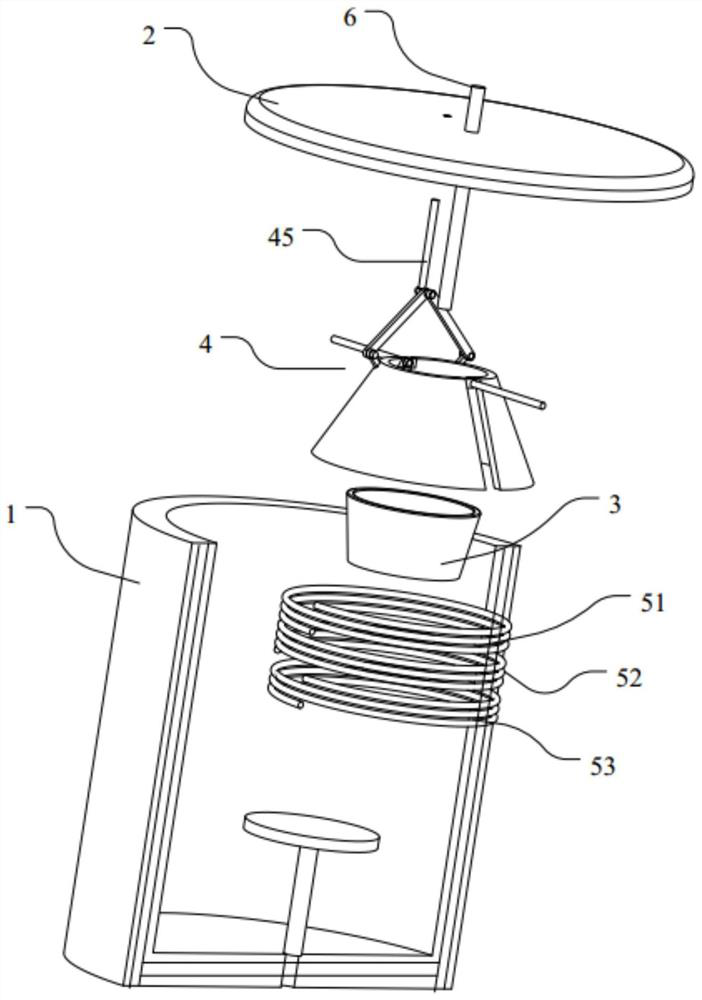

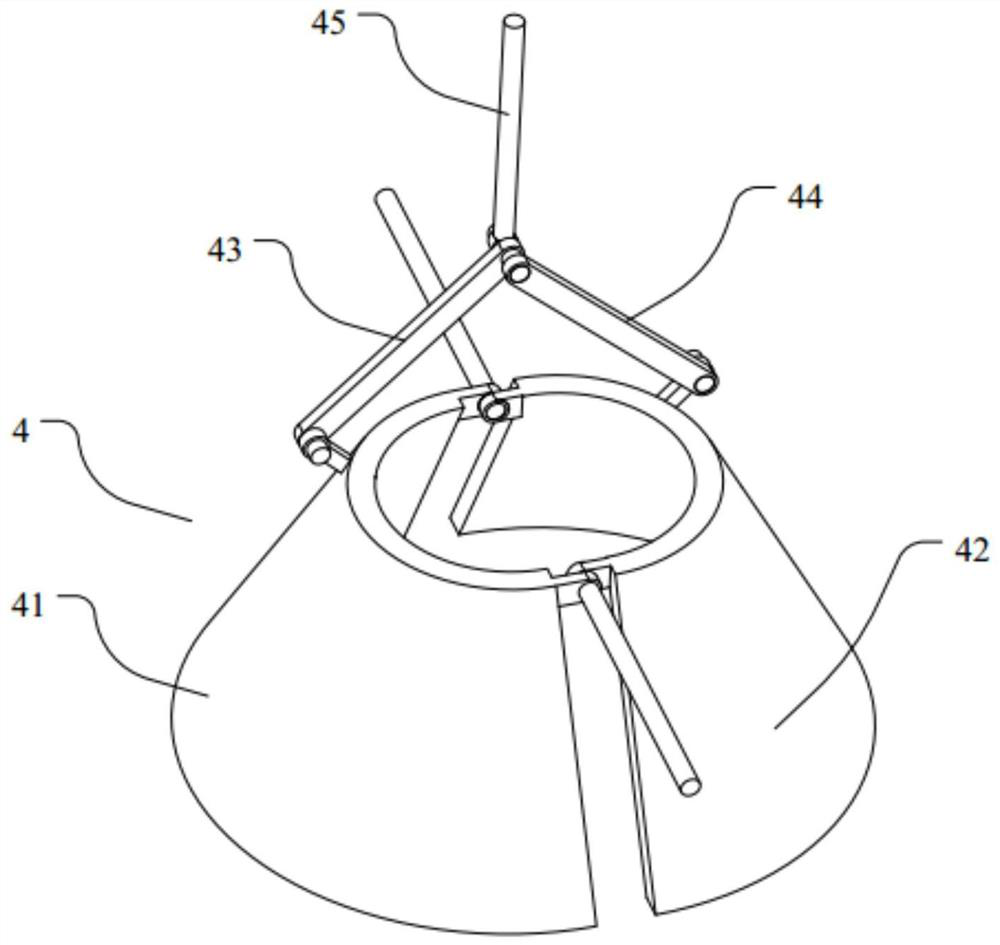

[0026] Such as Figure 1-3 As shown, the sapphire crystal growth furnace in the present invention is used to prepare sapphire crystals, and includes a furnace body 1 , a furnace cover 2 , a crucible 3 , and a temperature field regulating device 4 . The furnace body 1 is used to provide a growth environment for sapphire crystals. The furnace cover 2 is covered on the furnace body 1 to seal the furnace body 1 . The crucible 3 is arranged in the furnace body 1 and is used to hold the melt and serve as a reaction vessel. In this embodiment, the melt is Al2O3, specifically, it may be block or powder, or a combination of the two.

[0027] The temperature field adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com