Saw-tooth mutual-lock type steel sleeper for automatic compensation of settlement

An automatic compensation and interlocking technology, applied to roads, buildings, ballast layers, etc., can solve problems such as uneven and uneven lines, and achieve the effect of solving unevenness, simple structure, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

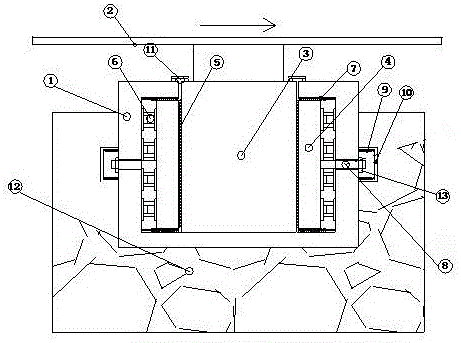

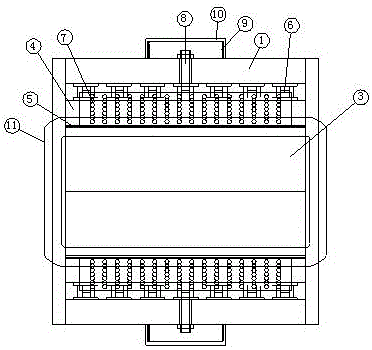

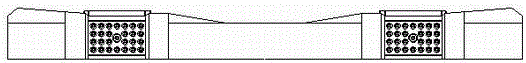

[0014] A sawtooth interlocking type settlement automatic compensation steel sleeper, comprising a steel sleeper 1, the steel sleeper 1 is laid on the ballast 12, characterized in that a lifting block 3 and a steel plate 4 are arranged in the inner cavity of the steel sleeper 1, and the lifting block 3 The two sides are respectively connected to the inner surfaces of two steel plates 4 through sawtooth 5, and there is a space between the sawtooth 5, and the upper end of the lifting block 3 is fixedly connected to the rail 2; Steel balls 7, spring blocks 6 are evenly arranged between the outer surface of the steel plate 4 and the inner wall of the inner cavity of the steel sleeper 1, one end of the screw rod 8 is fixed on the outer surface of the steel plate 4, and the other end passes through the inner wall of the steel sleeper 1 to the outside of the steel sleeper 1 , and fixed with bolts 13; the upper side of the lifting block 3 and the upper surface of the steel sleeper 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com