Open Type Elastic Short Sleeper Vibration Damping Track Structure

An elastic and short-rail technology, applied in the direction of tracks, roads, buildings, etc., to achieve the effects of anti-aging, high service life, and improved vibration damping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

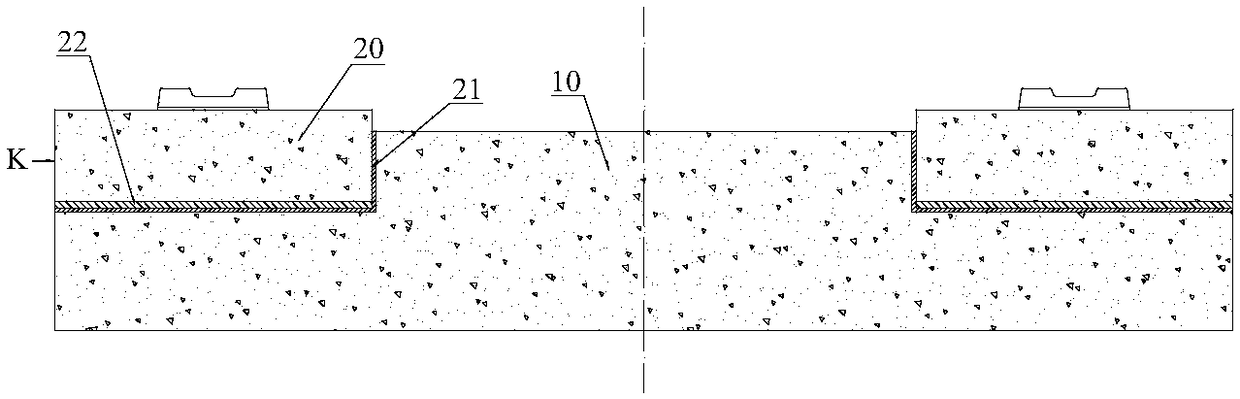

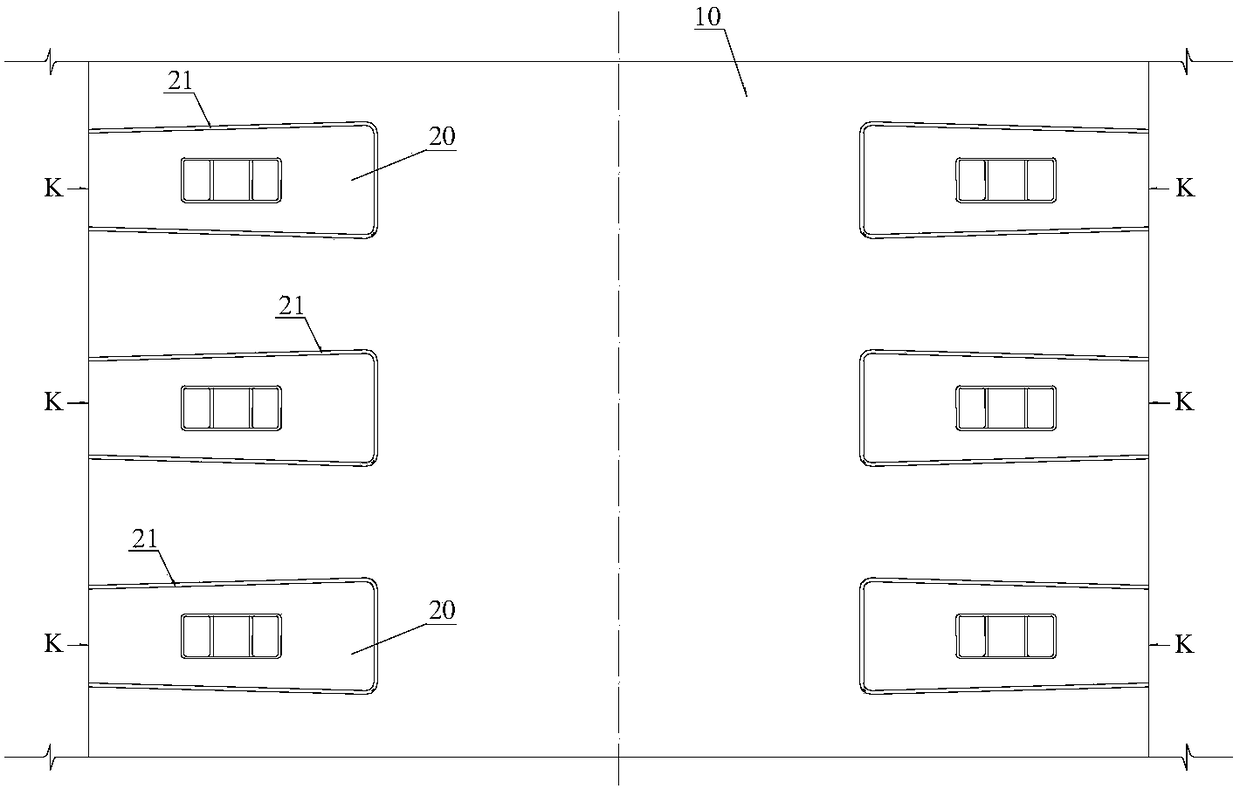

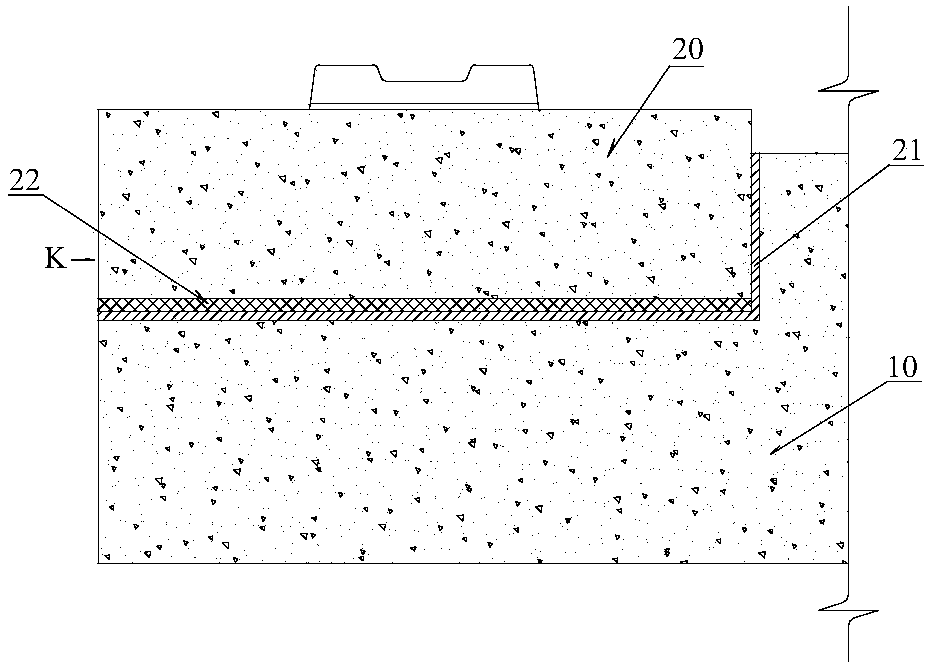

[0025] refer to figure 1 , figure 2 and image 3 , the open type elastic short sleeper vibration damping track structure of the present invention comprises an integral ballast bed 10 and elastic vibration damping components arranged at intervals along the line extension direction, the elastic vibration damping components are composed of short sleepers 20, elastic sheaths 21 and elastic cushions 22 , the elastic sheath 21 is set on the outer wall of the short sleeper 20, the elastic cushion layer 22 is arranged between the bottom surface of the short sleeper 20 and the bottom surface of the elastic sheath 21, and the embedding formed when the elastic damping parts are embedded in the cast-in-place integral ballast bed 10 in groove 11. The cross section of the short sleeper 20 has a variable cross section along the length direction, and the outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com