Mechanical check horizontal reciprocating grouting pipe and construction method thereof

A horizontal reciprocating, grouting pipe technology, applied in infrastructure engineering, construction, etc., can solve problems such as increased workload, waste of materials, damage to water-stop curtains, etc., to reduce labor and material costs, ensure the overall sealing effect, simplify The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

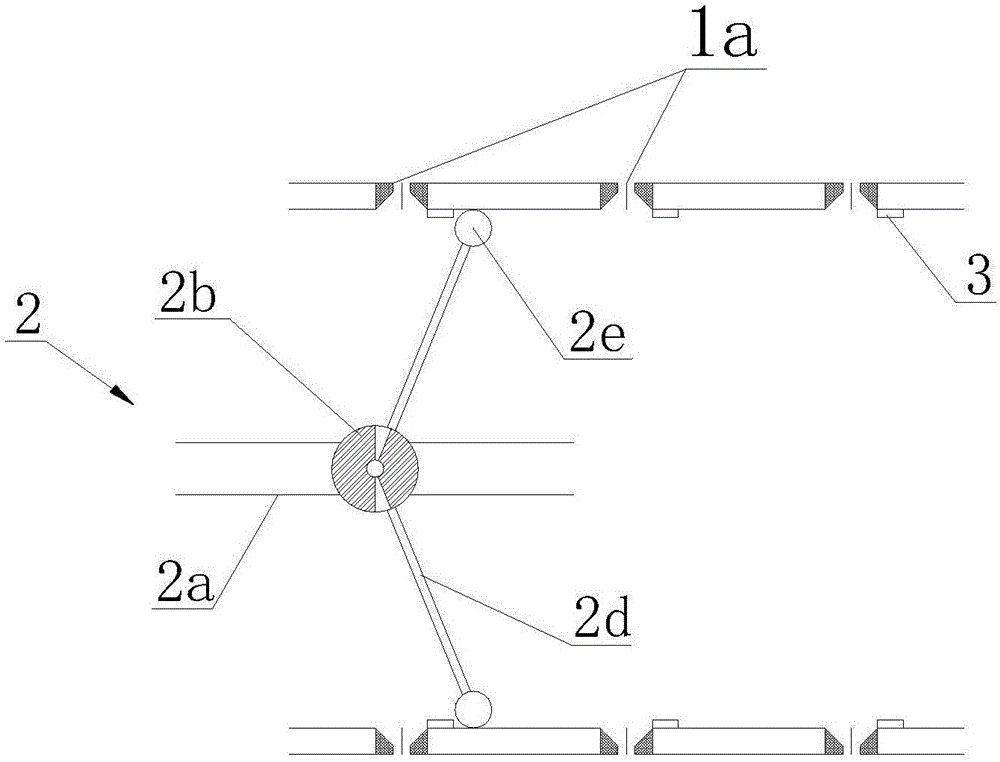

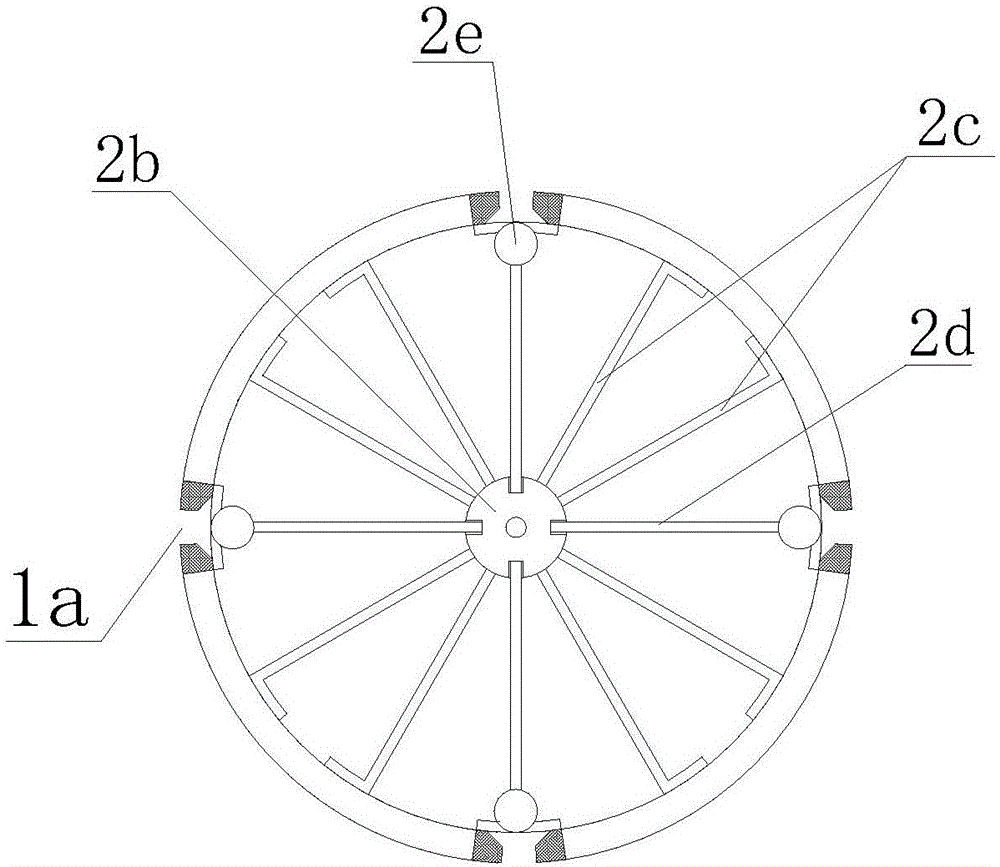

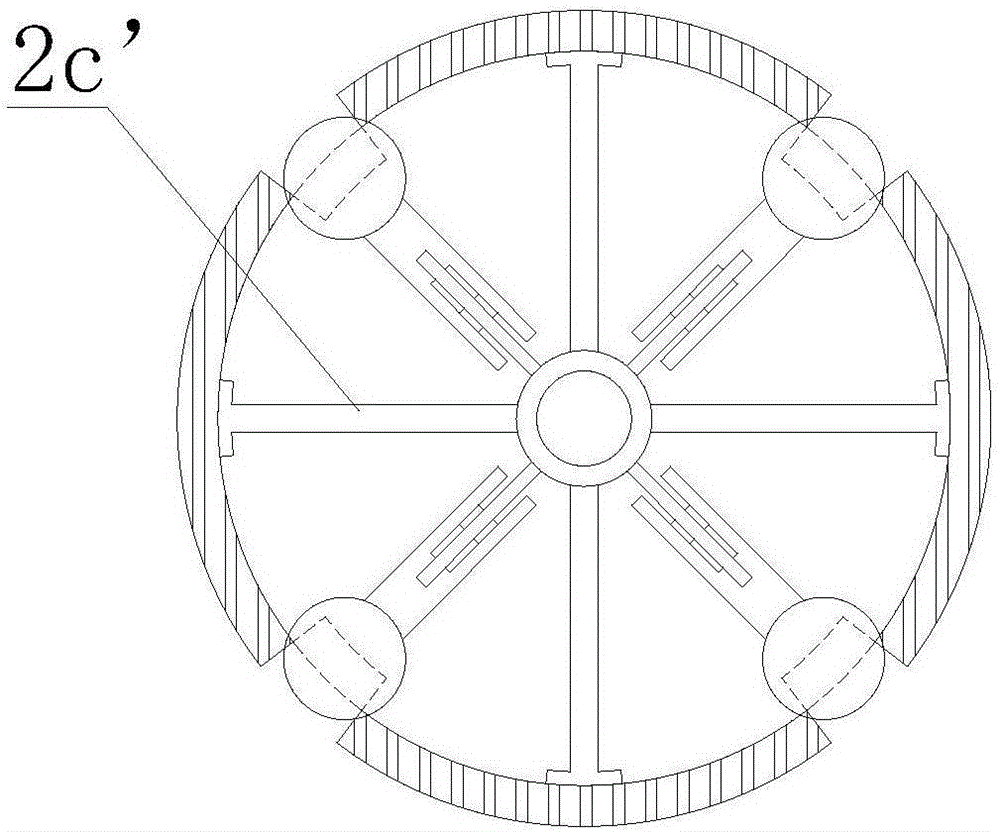

[0039] combine Figure 1 to Figure 4 As shown, a mechanical non-return horizontal reciprocating grouting pipe includes a horizontally arranged grouting outer pipe 1 and a built-in grouting device 2 that can move on the inner wall of the grouting outer pipe, along the axis of the grouting outer pipe There are several grouting holes 1a at intervals in the radial direction and the circumferential direction. There are 4 grouting holes in each radial section, and the angle between the centers of the circles is a right angle. The grouting outer pipe adopts a profile with a length of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com