Hydraulic drag reducer

A drag reducer and hydraulic technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of drilling and grinding speed limitation, bit application, tubing can't go down, etc., to ensure normal lifting and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

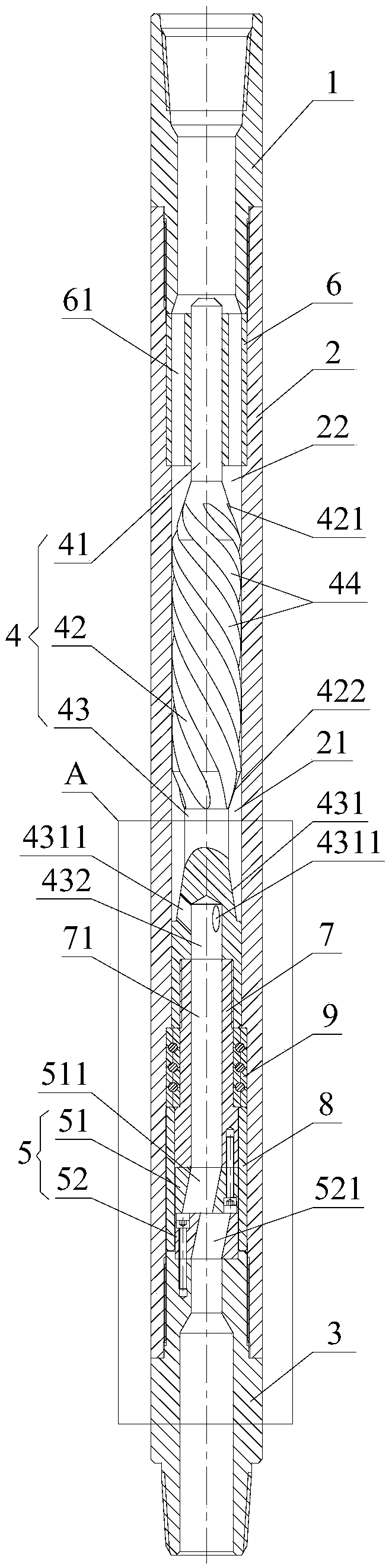

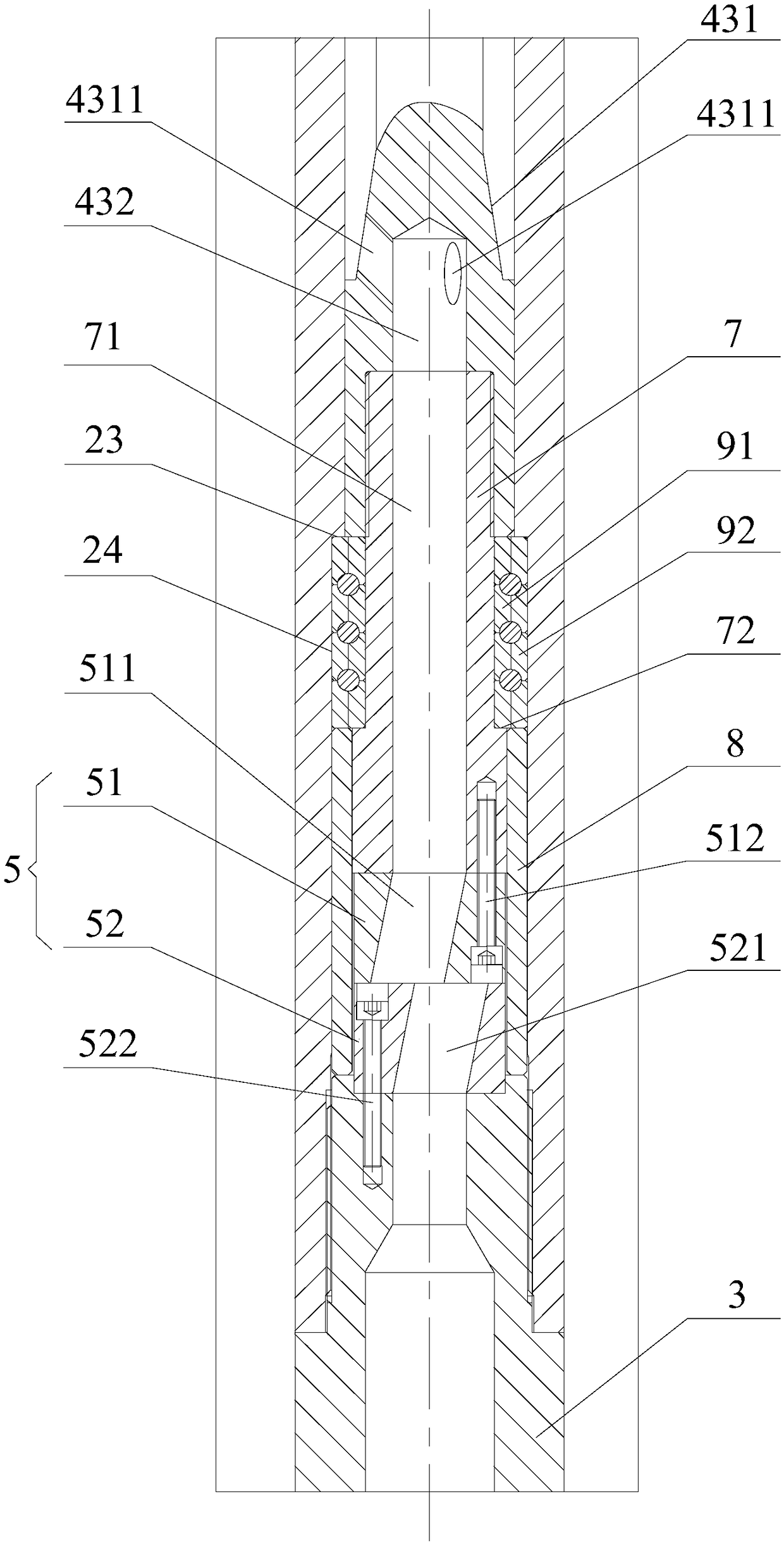

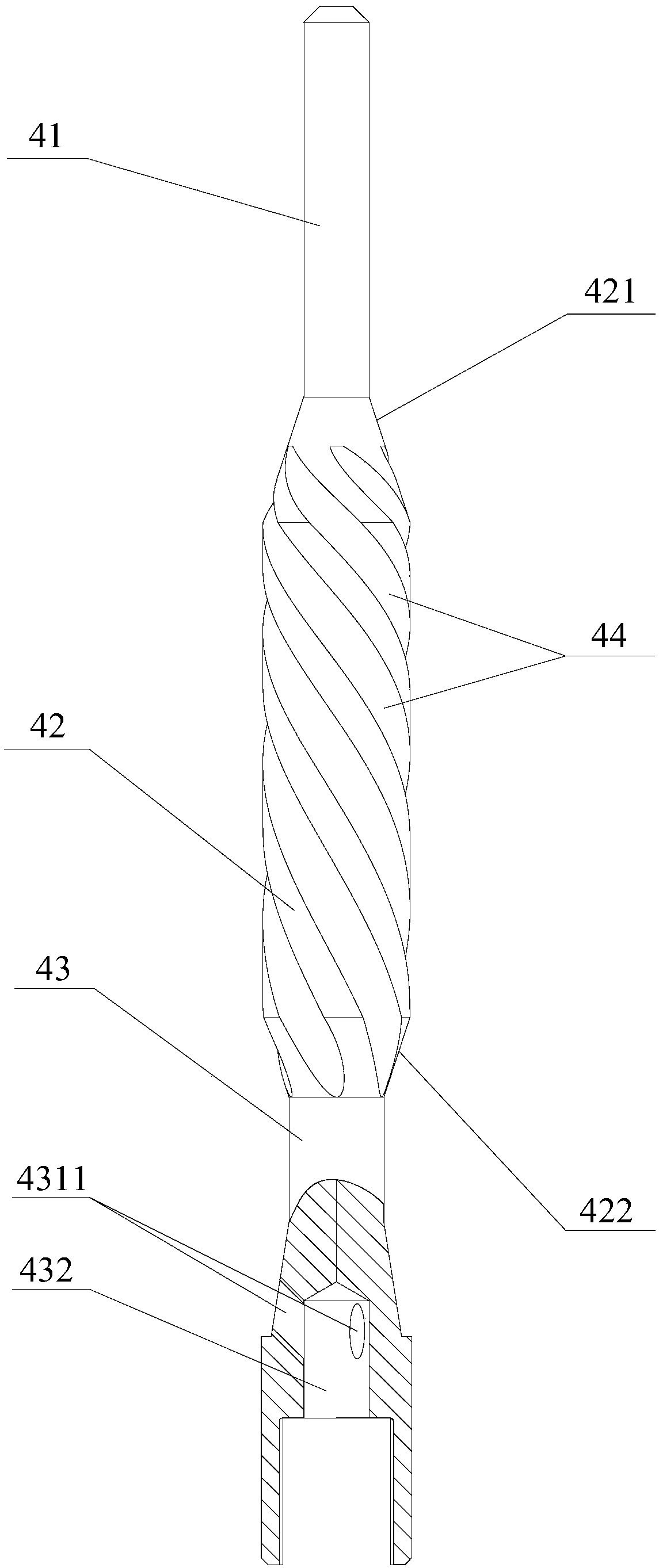

[0064] Such as figure 1 and figure 2 As shown, the present invention provides a hydraulic drag reducer, wherein the hydraulic drag reducer includes an upper joint 1, a housing 2 and a lower joint 3 connected in sequence from top to bottom, the upper joint 1, the housing 2 Both the upper joint and the lower joint 3 are tubular structures that penetrate up and down and are hollow inside. When in use, the fluid enters the interior of the housing 2 from the upper joint 1, reaches the lower joint 3 along the axial direction of the housing 2, and flows out from the lower joint 3. The inside of the housing 2 is provided with a rotor 4 and a disc valve assembly 5, the rotor 4 is rotatably arranged inside the housing 2, the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com