Combustion method and device for pulverized coal in upper combustion chamber of sleeve kiln

A technology of pulverized coal combustion and combustion chamber, which is applied in the direction of combustion methods, burners for burning powder fuel, burners, etc., which can solve the problems of continuous normal production, small internal space, and difficulty in cleaning, etc., to reduce the workload of slag removal , to ensure the effect of continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

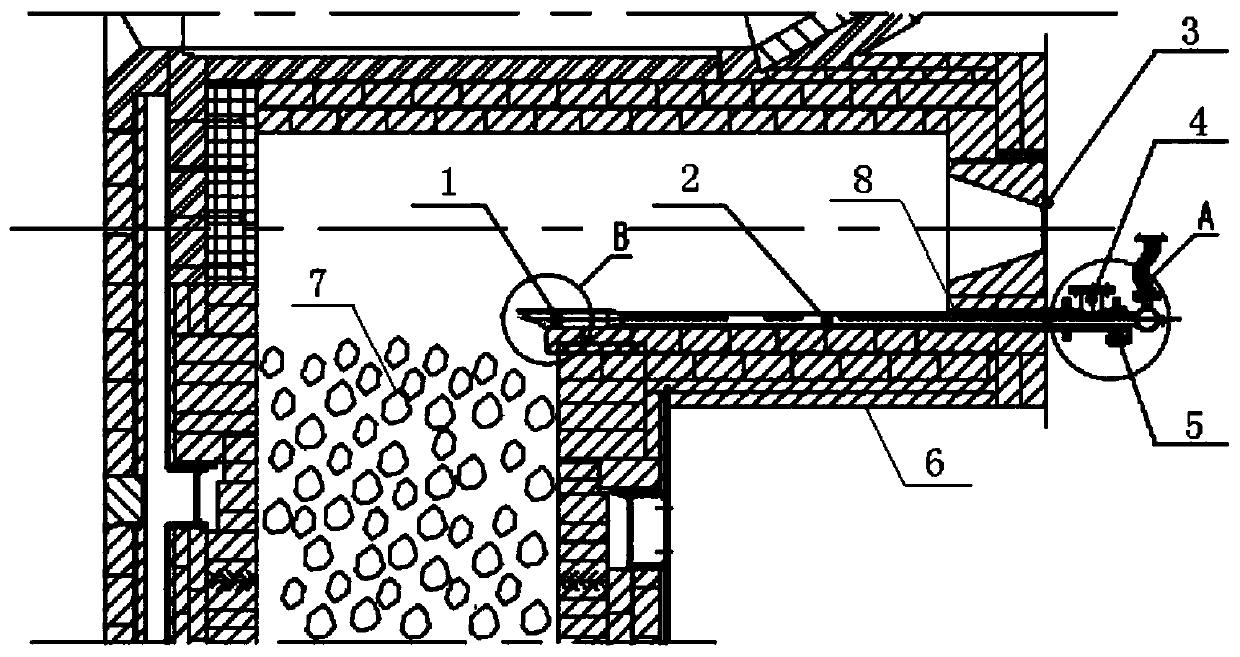

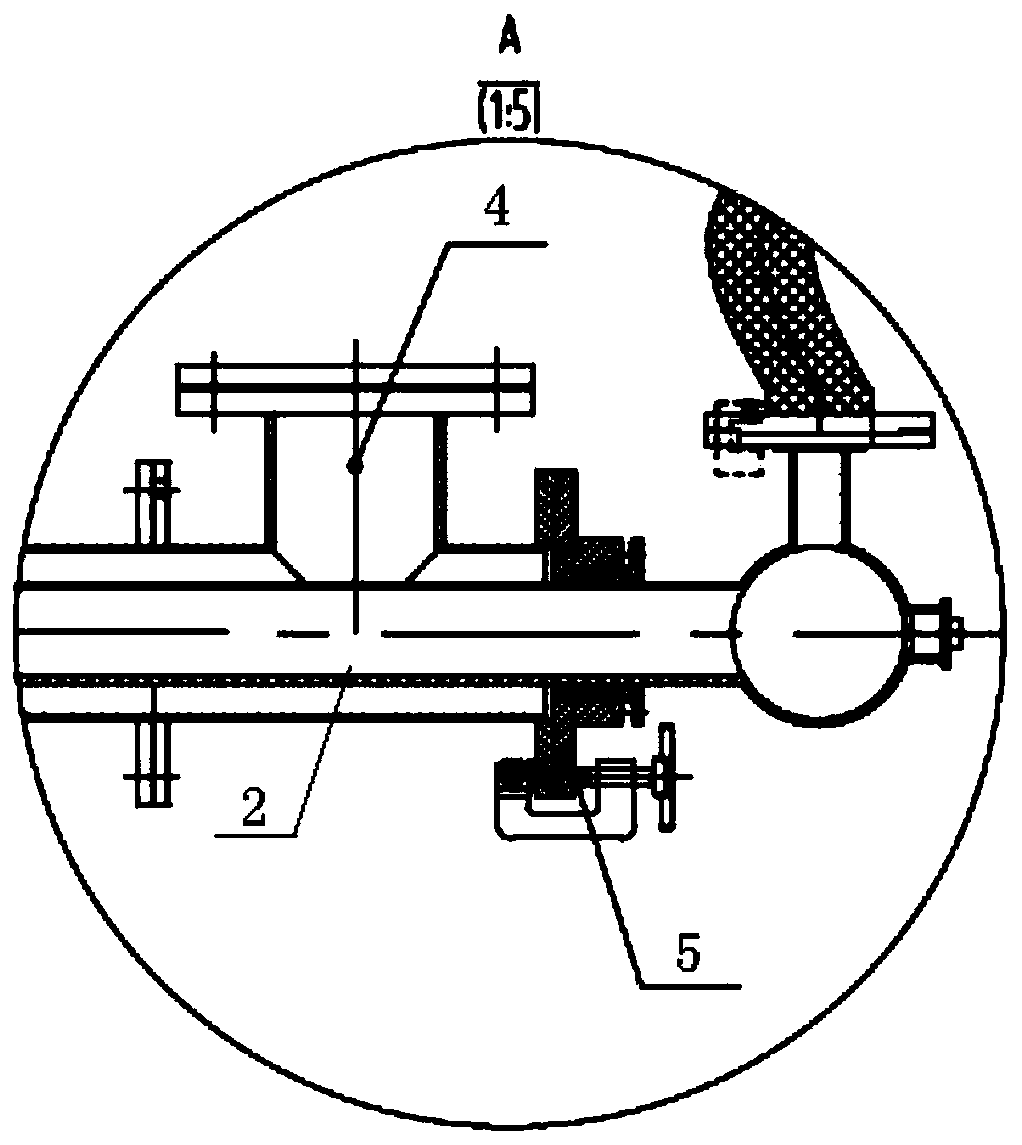

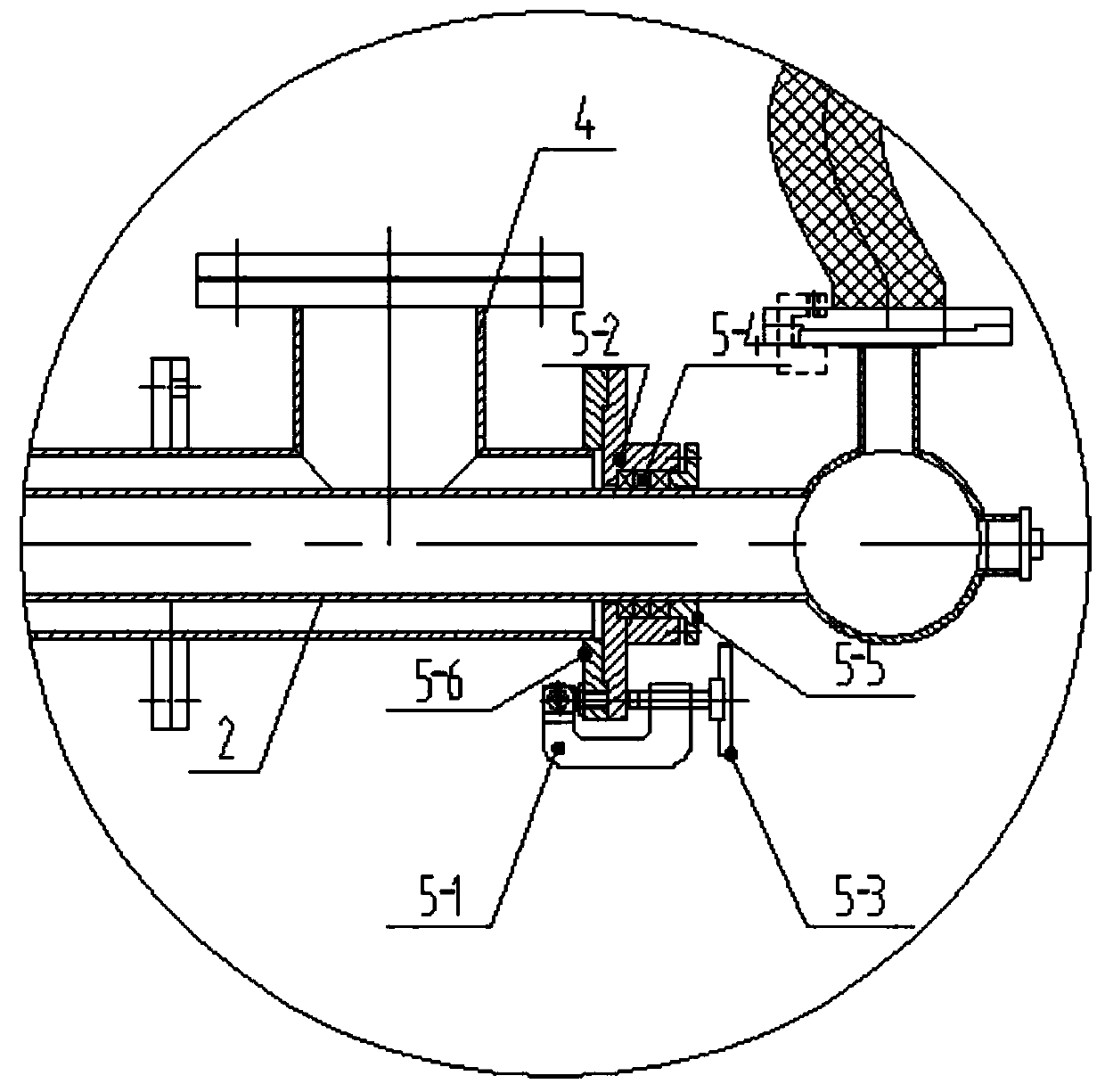

[0020] like figure 1 As shown, the pulverized coal combustion method in the upper combustion chamber of the sleeve kiln of the present invention is used for the combustion of pulverized coal in the upper combustion chamber 6 when the sleeve kiln uses pulverized coal as fuel, and the front end of the upper combustion chamber 6 is provided with a combustion chamber The panel 3 and the end of the upper combustion chamber 6 communicate with the sleeve kiln material layer 7. The method includes: setting a burner coal injection pipeline 2 on the combustion chamber panel 3, and the burner coal injection pipeline 2 is connected to the burner combustion-supporting air channel 4. The outlet end of the burner coal injection pipeline 2 extends to the end of the upper combustion chamber 6, and the burner coal injection pipeline 2 can move back and forth along the center line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com