Precision geometric leveling measurement vertical ruler righting device and operating method thereof

A technology of leveling measurement and leveling rod, which is applied in the direction of measuring devices, height/level measurement, measuring instrument components, etc., and can solve problems such as large round-trip discrepancy errors of measuring sections, unstable leveling rods, and small but insignificant differences. , to achieve the effect of eliminating errors, shortening the measurement time, and being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

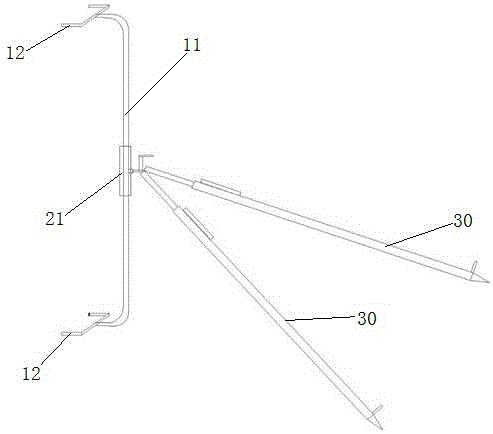

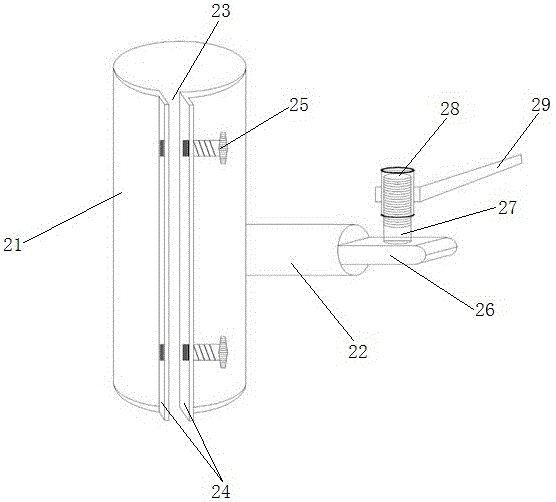

[0037] In order to overcome the problem that the vertical ruler of the leveling rod is not stable when it is straightened up and the tilt error of the vertical ruler of the leveling rod exists, this embodiment provides a method such as Figure 1 to Figure 10 The shown straightening device for the precision geometric leveling ruler includes a leveling rod fixing unit, a lifting clamp connector and a telescopic bracket, and the leveling rod fixing unit includes a fixing rod 11 and two ruler fixing clips 12 , the two ends of the fixed connecting rod are respectively connected with a scale fixed connecting clamp 12, and the lifting and fixing clamp connector includes a card sleeve 21 and a transverse connecting rod 22, and the described card sleeve 21 is set on the outside of the fixed connecting rod 11, and the card sleeve 21 is provided with a lock slit 23 along the axial direction, and each side of the lock slit 23 is connected to a connecting plate 24, and the two connecting pl...

Embodiment 2

[0046] On the basis of embodiment 1, this embodiment provides a kind of figure 1 As shown in the precision geometric leveling ruler straightening device and its operation method, the fixed connecting rod 11 includes a straight rod, and the two ends of the straight rod are respectively arranged as arc rods, and the arc rod and the scale are fixedly connected with a clamp 12 connections.

[0047] like Figure 4 As shown, the two rulers are fixedly connected with clips 12 and are fastened at 1 / 3 and 2 / 3 of the back of the leveling ruler body. In order to ensure the stability of the device, the card sleeve 21 is set on the outside of the straight rod of the fixed connecting rod 11, as Figure 5 As shown, when the point of the ruler is flush with the ground, the cartridge 21 is fastened to the midpoint of the straight rod on the solid connecting rod 11, as Figure 6 As shown, when the point of the ruler protrudes from the ground, the cartridge 21 should be adjusted downward along...

Embodiment 3

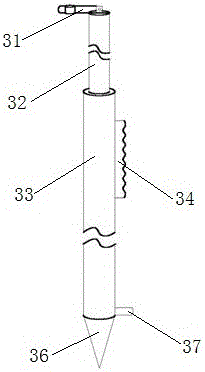

[0050] On the basis of embodiment 2, this embodiment provides a kind of precise geometrical leveling ruler straightening device and its operation method, in order to facilitate installation and disassembly, such as Figure 8 As shown, the upper end of the telescopic inner rod 32 is provided with a connector 35, and the connector 35 is provided with a connecting hole, as Figure 9 and Figure 10 As shown, the two sides of the U-shaped butt joint 313 are oppositely provided with butt holes 314, and the connector 35 is located in the U-shaped butt joint 313. The connection hole of the connector 35 communicates with the two butt holes 314, and through The three holes are inserted into the horizontal axis screw to connect the connector 35 and the U-shaped butt joint 313 .

[0051] like image 3 As shown, the grip type fastening lock 34 is arranged on the outer side of the outer rod 33, and is used to adjust the length of the telescopic inner rod 32 inserted into the outer rod 33....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com