Portable automobile gearbox shaft vibration detector

A portable, detector technology, applied in the field of detection, can solve problems such as backwardness, and achieve the effect of being convenient to carry, enhancing practicability and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

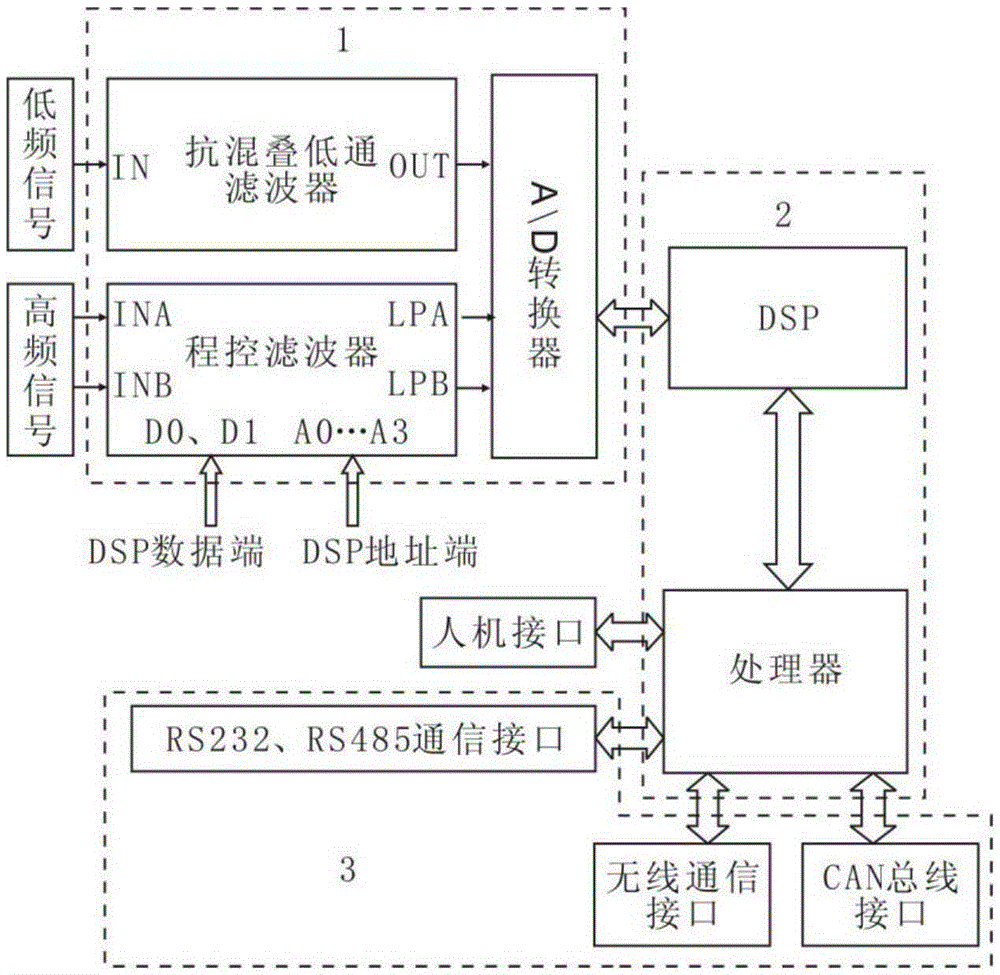

[0019] The load of the machine is all carried by the bearings, so there will be many problems, such as symmetry, unbalance and other problems. These problems will cause the machine to vibrate and transmit this vibration to the bearing. Therefore, we can judge whether the wind turbine is faulty and whether the bearing is defective by testing the bearing.

[0020] Bearing surfaces are often worn or otherwise damaged. The bearings are loose and unbalanced due to long-term use, improper installation of the machine and excessive load are also causes of failure.

[0021] When measuring rolling bearings in reality, the outer ring of the bearing is usually measured, and the measurement method is to place the vibration sensor on the bearing seat.

[0022] Since the low-frequency vibration below 10Hz will cause considerable displacement, the displacement sensor is generally used to measure the low-frequency vibration signal. For high-frequency vibration signals, an acceleration sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com