Battery module with water-cooling heat dissipation for tabs

A battery module, water-cooled heat dissipation technology, applied in batteries, secondary batteries, circuits, etc., can solve the problems of poor water-cooled heat dissipation, low production efficiency, and large space occupation, and achieves simple assembly, high assembly efficiency, and avoidance. effect of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of the present invention will not be limited.

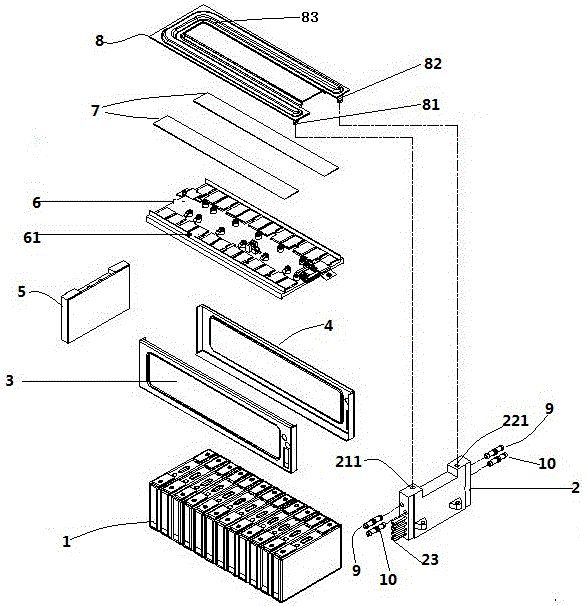

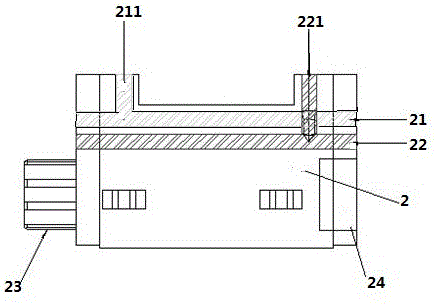

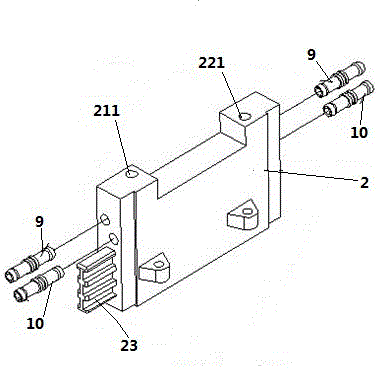

[0029] In this example, figure 1 The exploded diagram of the battery module with ear water cooling and heat dissipation is given, figure 2 A schematic structural view of the front-end plate of the present invention is given, image 3 A schematic diagram of the structure of the water inlet connector, water outlet connector and front-end board is given, refer to figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a battery module with ear water cooling and heat dissipation, including several battery module units, wherein the battery module unit includes: battery pack 1, battery pack 1 is composed of several battery cells ; the front end plate 2 arranged on the front side of the battery pack; the left side plate 3 and the right side plate 4 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com