Automatic cabling device for transmission line

A technology for routing devices and transmission lines, which is applied in the direction of overhead lines/cable equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

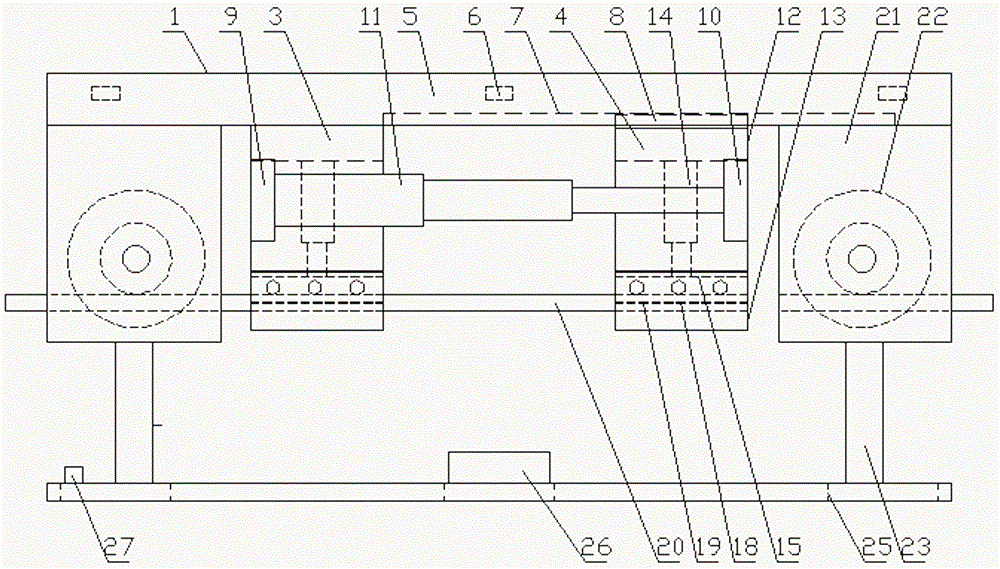

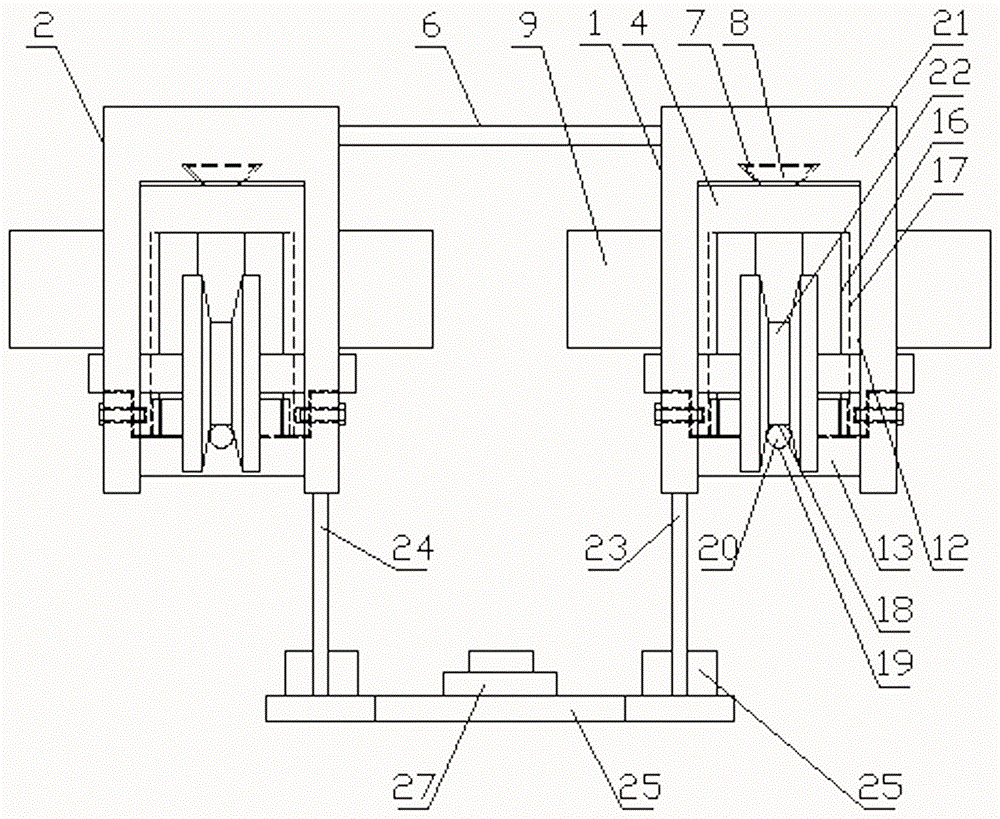

Embodiment 1

[0037] Such as figure 1 with figure 2 As shown, an automatic routing device for power transmission lines includes a front traveling mechanism 1 and a rear traveling mechanism 2 with the same structure, and a routing mechanism arranged at the bottom of the front traveling mechanism 1 and the rear traveling mechanism 2, the Front traveling mechanism 1 and described rear traveling mechanism 2 all comprise left traveling support 3 and right traveling support 4, and described left traveling support 3 tops are provided with crossbeam 5, and the crossbeam 5 of described front traveling mechanism 1 and described rear traveling mechanism 2 The crossbeams 5 are connected by upper connecting rods 6, the bottom surface of the crossbeams 5 is provided with a first dovetail groove 7, and the top of the right walking frame 4 is provided with a first dovetail tenon 8 matched with the first dovetail groove 7.

[0038] Base 9 is all set on the front and back sides of described left walking su...

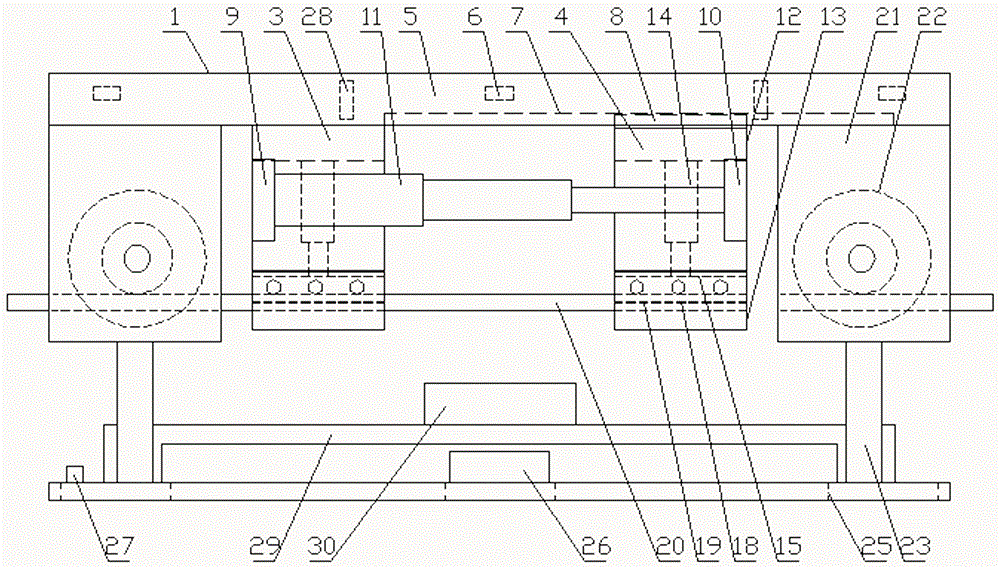

Embodiment 2

[0053] Such as image 3 with Figure 4 As shown, an automatic routing device for power transmission lines includes a front traveling mechanism 1 and a rear traveling mechanism 2 with the same structure, and a routing mechanism arranged at the bottom of the front traveling mechanism 1 and the rear traveling mechanism 2, the Front traveling mechanism 1 and described rear traveling mechanism 2 all comprise left traveling support 3 and right traveling support 4, and described left traveling support 3 tops are provided with crossbeam 5, and the crossbeam 5 of described front traveling mechanism 1 and described rear traveling mechanism 2 The crossbeams 5 are connected by upper connecting rods 6, the bottom surface of the crossbeams 5 is provided with a first dovetail groove 7, and the top of the right walking frame 4 is provided with a first dovetail tenon 8 matched with the first dovetail groove 7.

[0054] Base 9 is all set on the front and back sides of described left walking su...

Embodiment 3

[0066] Such as Figure 5 with Image 6 As shown, the difference between it and Embodiment 2 is that a traction plate 31 is provided at the bottom of the front wiring support 23 and the rear wiring support 24, and a traction hole 32 is opened on the traction plate 31, and the traction hole 32 Traction rope 33 is set inside.

[0067] An anchor rod is arranged at the lower end of the traction rope 33 .

[0068] In this embodiment, a traction plate is provided at the bottom of the front wiring support and the rear wiring support, and a traction hole is set on the traction plate so as to fix the traction rope on the traction plate, so that the ground personnel can use the traction rope to prevent the original The device dances, and an anchor rod is set at the lower end of the traction rope so that the device is temporarily fixed on the ground by the traction rope. Obviously, an anchor is set at the lower end of the traction rope to also have the same effect.

[0069] In the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com