Curable silicone resin composition, and cured product thereof

A technology of resin composition and silicone, which is applied in the direction of electrical solid devices, semiconductor/solid device components, instruments, etc., can solve the problem of simultaneously satisfying sulfur barrier and thermal shock resistance, sealing material damage thermal shock resistance, Reduced sulfur barrier properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0392] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited to these examples. In addition, the unit of the compounding ratio of each component shown in Table 1 is a weight part.

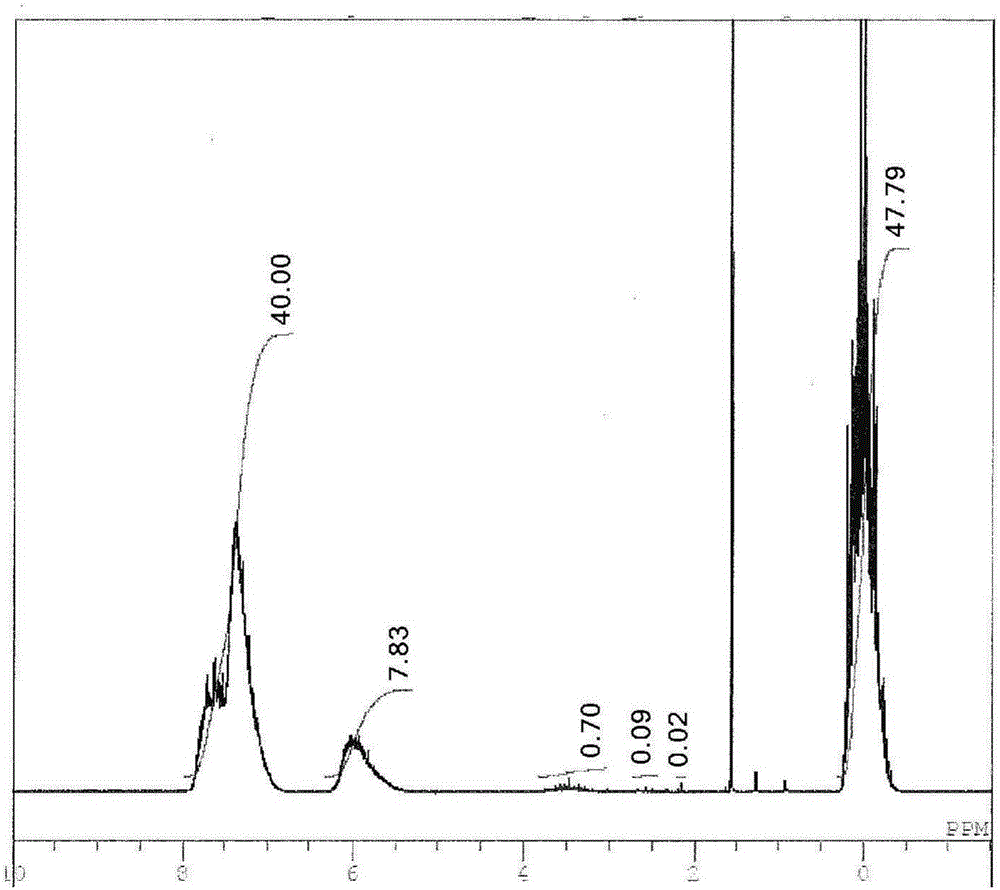

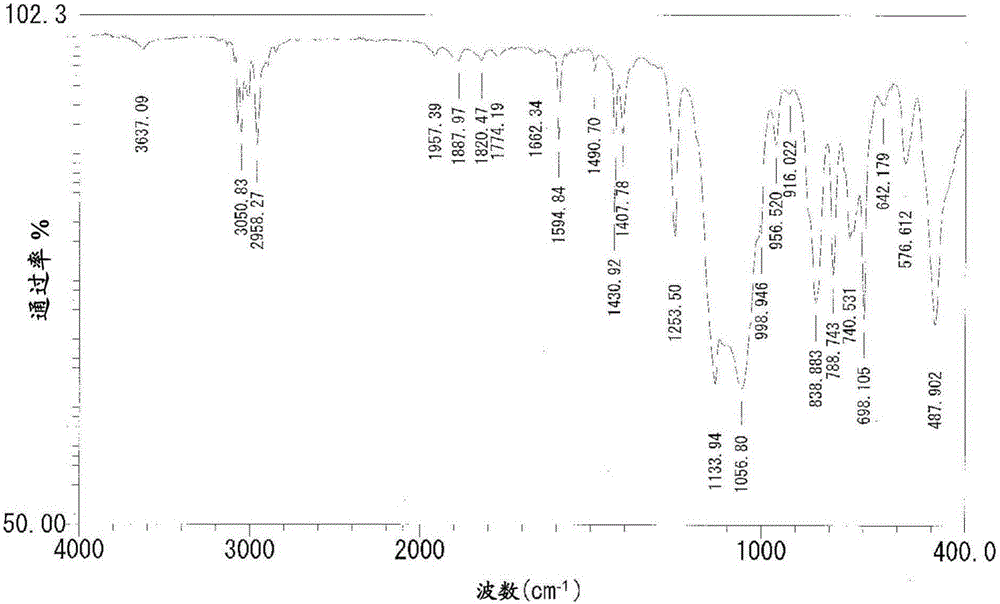

[0393] Products and products produced in Synthetic Examples 1 H-NMR analysis was performed using JEOL ECA500 (500 MHz). In addition, the number average molecular weight and weight average molecular weight of the above-mentioned products and products were measured using Alliance HPLC system 2695 (manufactured by Waters), Refractive Index Detector 2414 (manufactured by Waters), column: Tskgel GMH HR -M×2 (manufactured by Tosoh Co., Ltd.), guard column: Tskgel guard column H HR L (manufactured by Tosoh Co., Ltd.), column oven: COLUMN HEATER U-620 (manufactured by Sugai), solvent: THF, measurement conditions: 40°C.

Synthetic example 1

[0395] [Manufacture of polyorganosilsesquioxane having a vinyl group]

[0396] In a 100ml flask (reaction vessel) equipped with a thermometer, a stirring device, a reflux condenser, and a nitrogen inlet pipe, 65 millimoles (9.64 g) of vinyltrimethoxysilane and 195 millimoles of phenyltrimethoxysilane were fed under nitrogen flow. mole (38.67g) and 8.31g of methyl isobutyl ketone (MIBK), and the mixture was cooled to below 10°C. 360 mmol (6.48 g) of water and 0.24 g (1.2 mmol as hydrogen chloride) of 5N hydrochloric acid were added dropwise to the above mixture. Thereafter, 40 g of MIBK was added to dilute the reaction solution.

[0397] Next, the temperature of the reaction container was raised to 70°C. 520 millimoles (9.36 g) of water was added thereto, and polycondensation reaction was performed under nitrogen flow. Next, 130 millimoles (21.11 g) of hexamethyldisiloxane were added to the reaction solution after the polycondensation reaction, and the mixture was stirred at...

Embodiment 1

[0419] As shown in Table 1, first, component (D) was dispersed in a mixture of 19.5 parts by weight of the trade name "ETERLED GS5145A" and 0.5 parts by weight of the trade name "AEROSIL R976" using a disperser (manufactured by Primix Co., Ltd., model: LB). (AEROSIL R976), thus preparing Agent A.

[0420] Then, in a manner to achieve the compounding ratio shown in Table 1, the A agent prepared above and the product name "ETERLEDGS5145B" (B agent) were mixed using a rotation and revolution stirring device (trade name "组太郎重食打机 (あわとり入太郎) ", manufactured by THINKY, model: ARE-310) were kneaded to produce a curable silicone resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap