End effector of manipulator for harvesting tomato fruit strings and method of end effector

A technology of end effector and manipulator, which is applied in the direction of harvester, agricultural machinery and implements, picking machine, etc., to achieve the effect of reliable work, excellent performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and example. The technical features in the following examples can be combined with each other if there is no conflict.

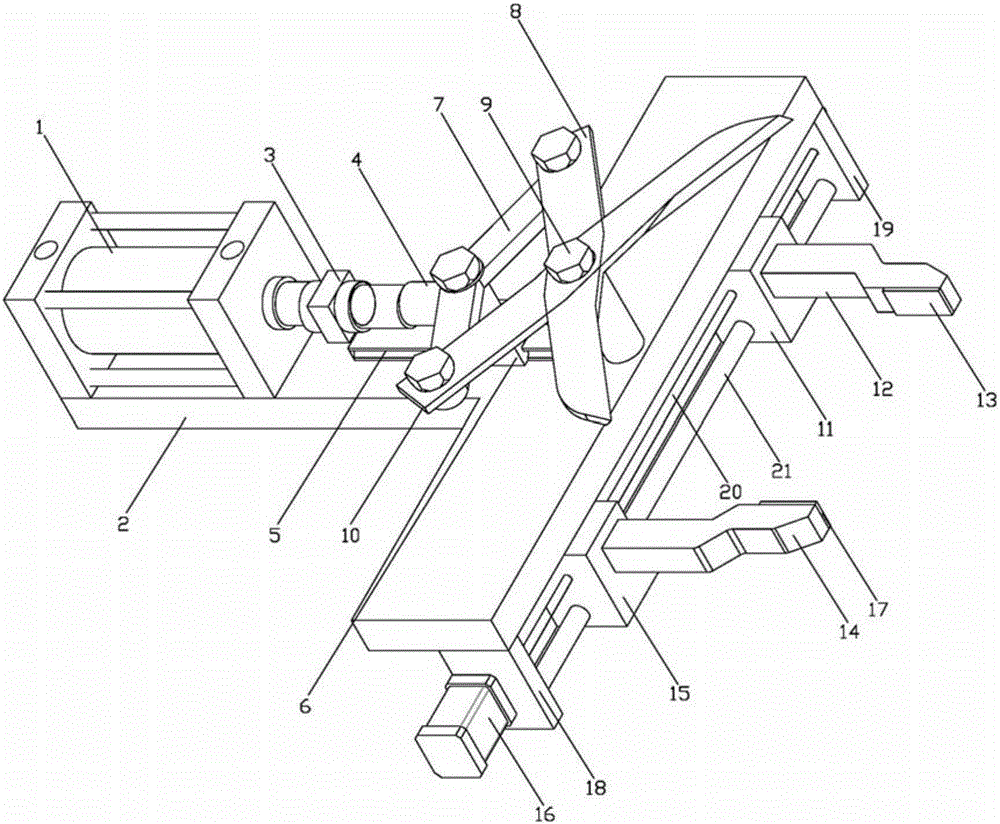

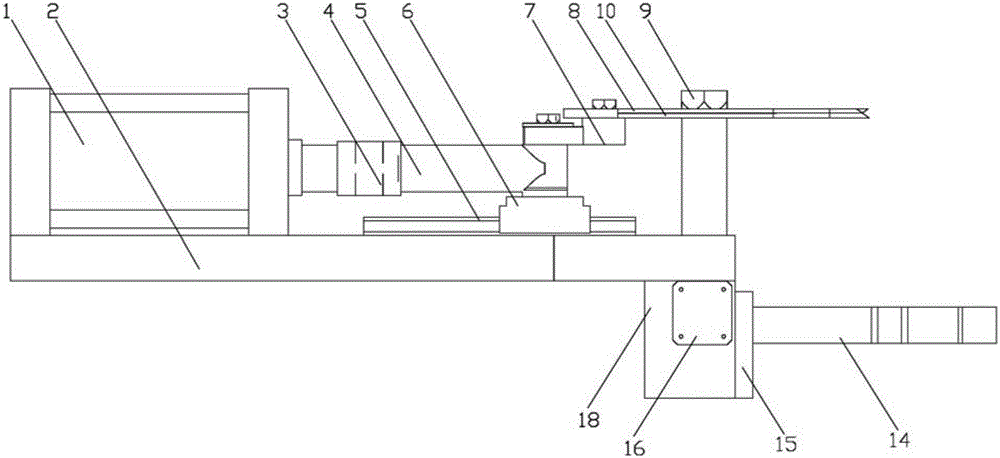

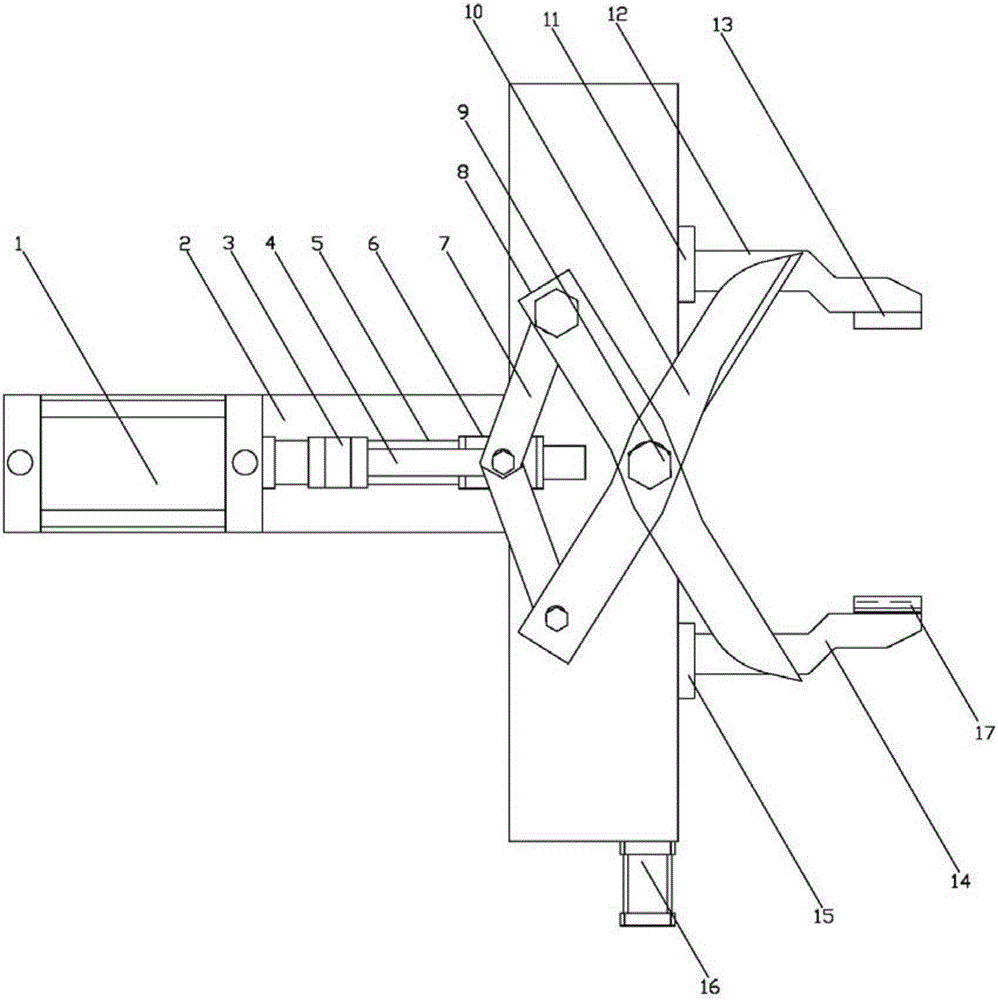

[0019] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the end effector of the tomato fruit bunch harvesting manipulator includes a T-shaped frame 2, a cutting mechanism, a clamping mechanism and a control system. The cutting mechanism is installed above the T-shaped frame 2, and the clamping mechanism is installed on the front and lower side of the T-shaped frame 2;

[0020] The clamping mechanism comprises a left-handed slider 11, a left clamping arm 12, a right clamping arm 14, a right-handed slider 15, a stepping motor 16, a flexible pad 17, a right bracket 18, a left bracket 19, a two-way screw mandrel 20, Guide rod 21, right support 18, left support 19 are respectively fixed on the bottom of T-shaped frame 2 two ends, two-way screw mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com