Array type meat cutting and skewering device

An array-type, meat-cutting technology, which is applied in the direction of processed meat, meat processing equipment, meat cutting/trimming, etc., can solve problems such as difficulty in ensuring sanitation, increasing meat pollution, and difficulty in ensuring the regularity of meat, and achieve maintenance And the effect of convenient maintenance, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

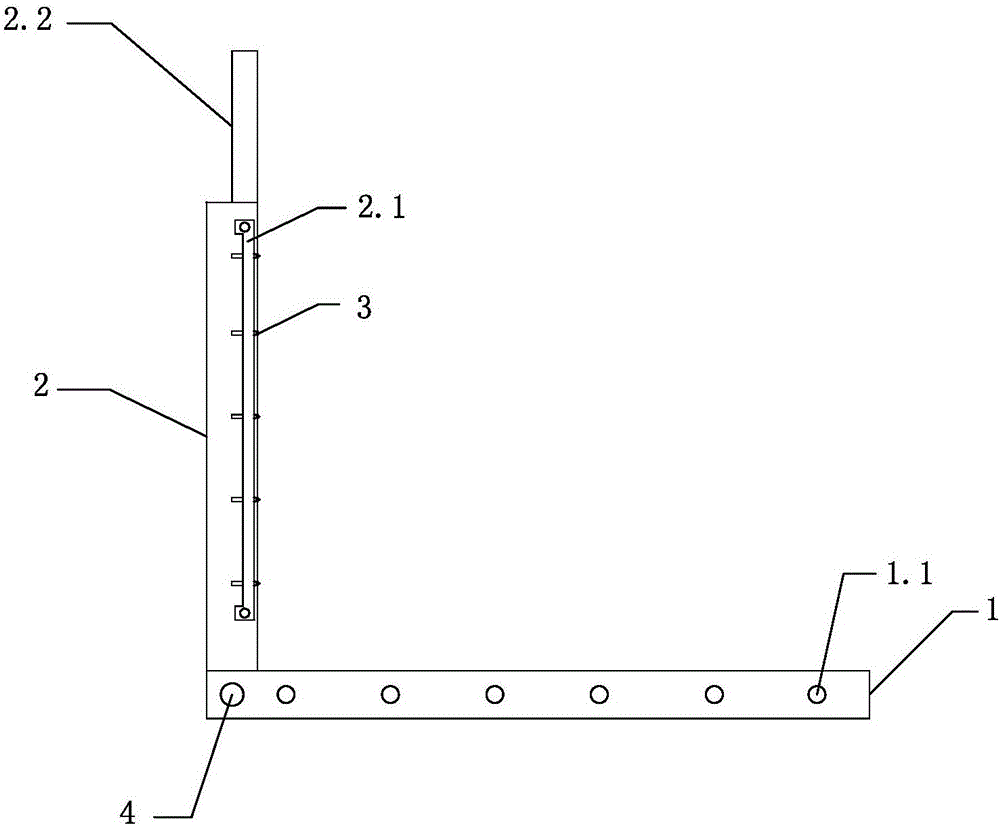

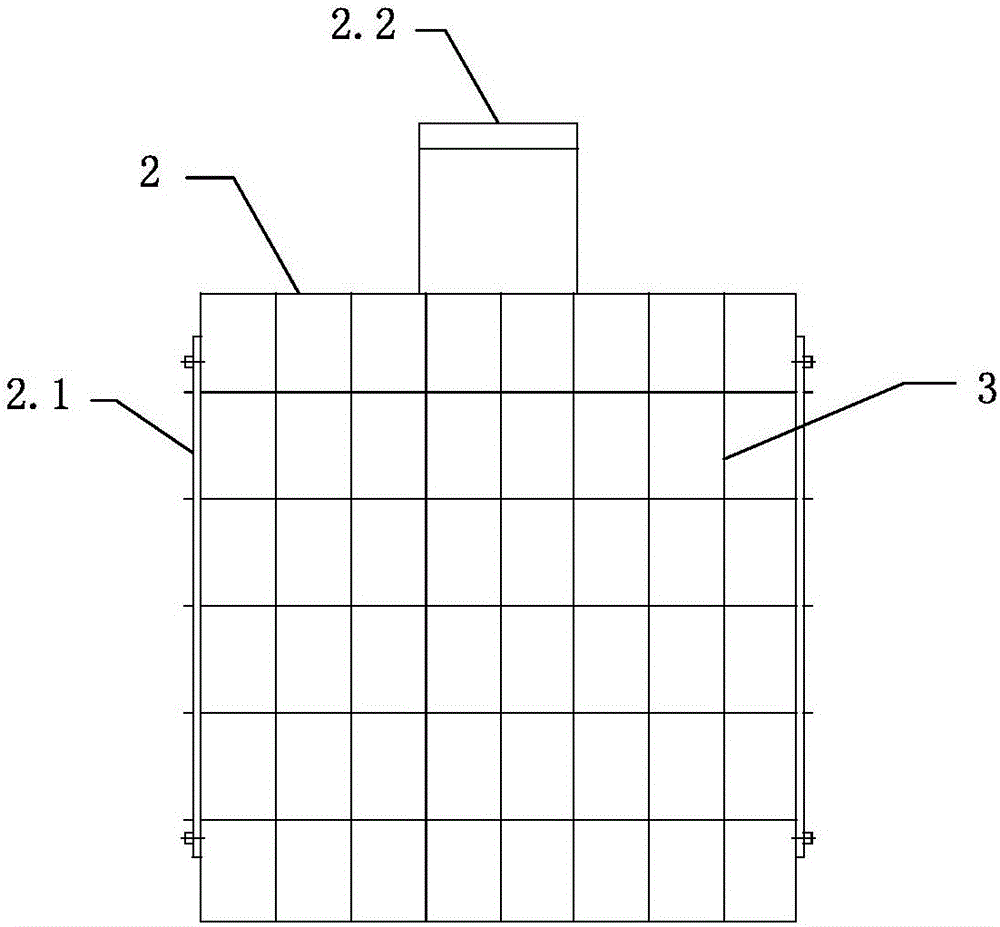

[0027] Such as figure 1 with figure 2 An array type meat skewering device shown includes: a cutting bottom frame 1, a cutting pressure frame 2 and a blade 3;

[0028] Wherein, the bottom end of the cutting bottom frame 1 and the top end of the cutting pressure frame 2 are hinged through the rotating shaft 4;

[0029] The four sides of the cutting bottom frame 1 are all processed with pinholes 1.1, and the centers of the pinholes 1.1 on each opposite side are coaxial;

[0030] The cutting bottom frame 1 is a rectangular frame with an open upper end and a rectangular accommodating cavity inside;

[0031] The cutting press frame 2 is a rectangular frame with a rectangular accommodation cavity inside with an open lower end:

[0032] Wherein, the cutting bottom frame 1 can be embedded in the rectangular accommodation cavity of the cutting pressure frame 2;

[0033] The frame of the cutting press frame 2 is provided with a plurality of blade fixing grooves 2.1;

[0034] The bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com