Konjak dicing and sorting assembly line equipment

An assembly line and slicing technology, used in conveyor objects, conveyors, metal processing, etc., can solve the problems of poisonous, easy to absorb water and swelling, and high viscosity of the whole konjac plant, achieve convenient placement and direction, avoid missed cuts, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

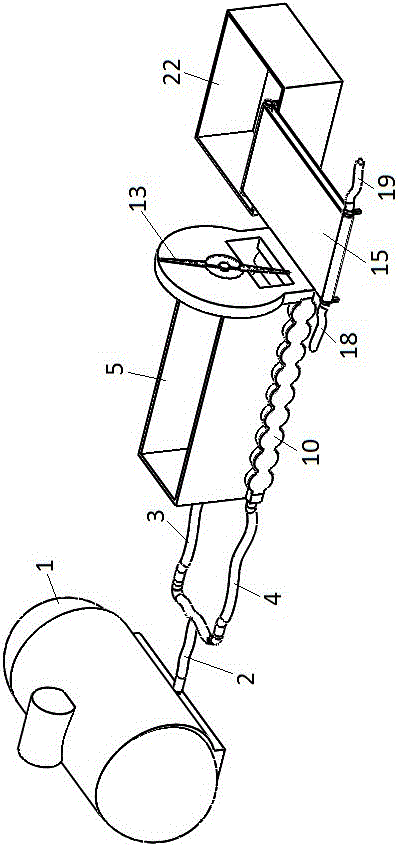

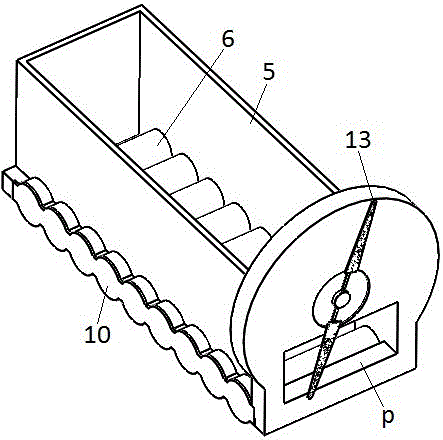

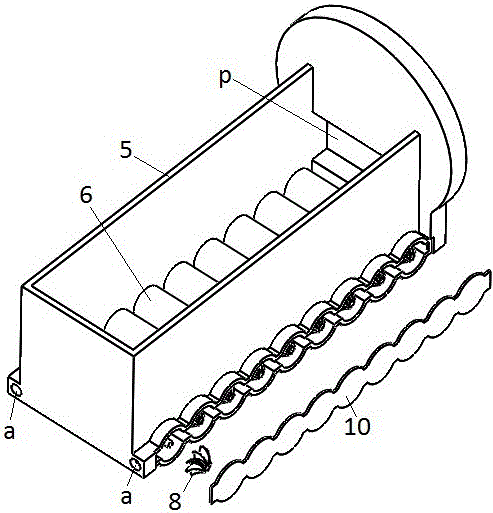

[0047] A kind of konjac slice sorting line equipment of the present invention will be described in further detail below in conjunction with accompanying drawings and embodiments.

[0048] A konjac slice sorting line equipment, more specifically, mainly includes an air compressor 1, a main air path for driving the material bucket 2, a driving air path 3 on the left side of the material loading bucket, and a driving air path 4 on the right side of the material loading bucket , material bucket 5, roller 6, roller shaft 7, left impeller 8, right impeller 9, impeller cover 10, cutter runner bearing 11, cutter runner 12, cutter 13, screw 14, conveyor belt 15 , conveyor belt driving roller 16, axial flow wind wheel 17, conveyor belt inlet pipe 18, conveyor belt outlet pipe 19, conveyor belt bearing 20, conveyor belt bracket 21, dehydration heating tank 22, bayonet pin 23;

[0049] Such as figure 1 As shown, it is divided into five parts according to the function, namely, the power p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com