Clamping groove type material floatation prevention device used in enzyme production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

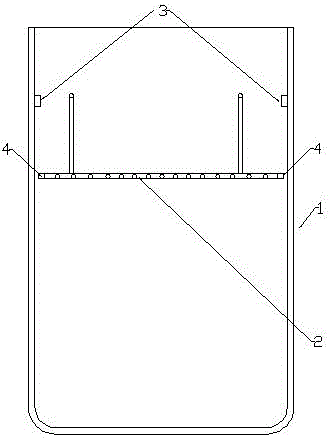

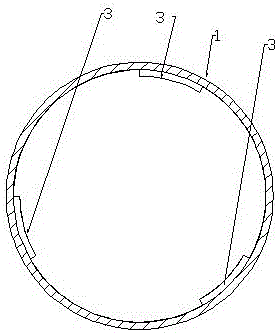

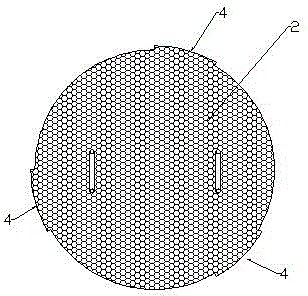

[0012] exist figure 1 , figure 2 , image 3 Among them, a briquetting block for preventing material from floating in enzyme production, which includes: grid-shaped metal pressure plate 1, cement briquette 2, the central position of the grid-shaped metal pressure plate 1 is vertically fixed with a positioning rod 3. The cement briquette 2 is cylindrical, and its central position is provided with a round hole 4 with a large bottom and a small top, and handles 5 are respectively symmetrically arranged on the left and right sides of the round hole 4. The round hole of the cement briquette 2 4 activities are inserted in the positioning rod 3.

[0013] Although the embodiments of the present invention have been shown and described, those skilled in the art are not limited thereto, and any changes or replacements that do not go through creative work should be covered within the protection scope of the present invention . Therefore, the protection scope of the present invention s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com