Fermentation cylinder applicable to soybean meal solid aerobic fermentation

An aerobic fermentation and fermentation tank technology, applied in the field of fermentation tanks, can solve problems such as sticky and greasy yield, and achieve the effects of avoiding stirring viscosity, fully fermenting effect, and changing fermentation means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

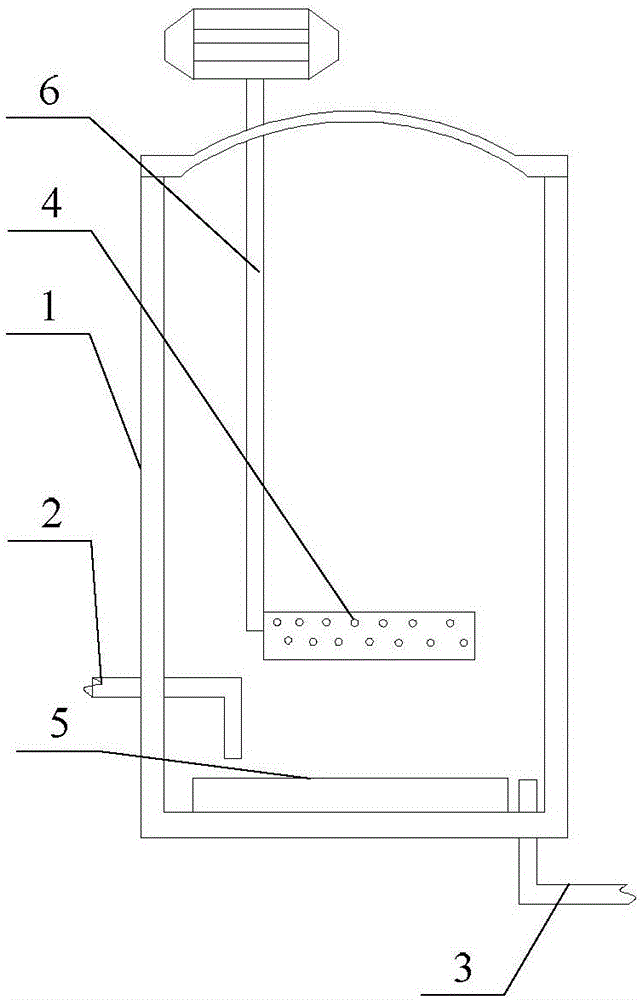

[0014] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the fermenter suitable for solid aerobic fermentation of soybean meal described in this embodiment, it includes tank body 1, bacterial liquid delivery pipe 2 and air intake pipe 3, it also includes raw material plate 4, bacterial liquid plate 5 and vibration lifting device 6,

[0015] The bacteria liquid tray 5 is located inside the tank body 1, the raw material tray 4 is connected to the vibration lifting device 6, is located inside the tank body 1, and is located above the bacteria liquid tray 5, and the raw material tray 4 is provided with a through hole;

[0016] The outlet of the bacterial liquid delivery pipe 2 is located in the bacterial liquid tray 5 ; the outlet of the air inlet pipe 3 is located at the bottom of the tank body 1 .

[0017] The vibration lifting device 6 is used to vibrate the raw material tray 4, put the raw material tray 4 into the inside of the bac...

specific Embodiment approach 2

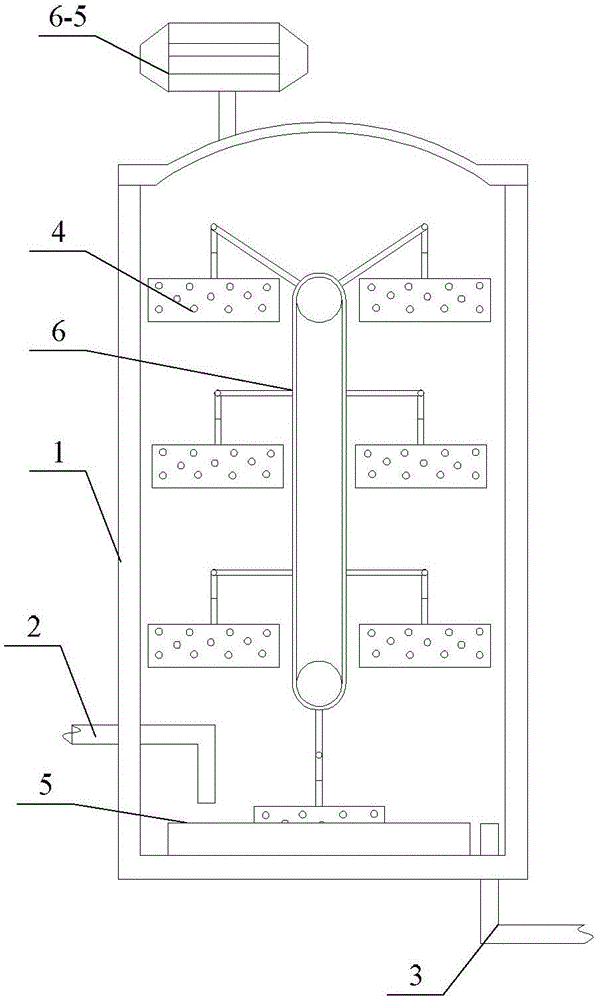

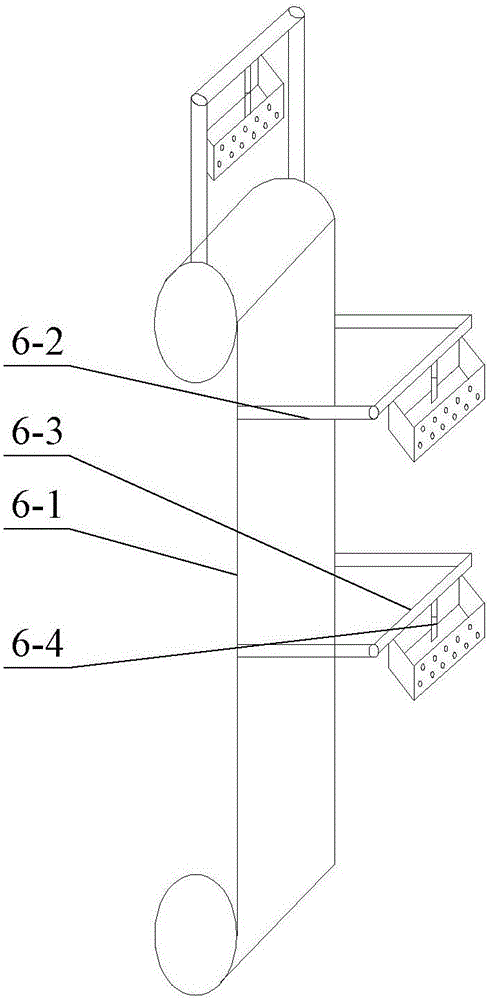

[0021] Specific implementation mode two: the following combination figure 2 with image 3 This embodiment will be described. There are multiple raw material trays 4 in this embodiment, and the plurality of raw material trays 4 are correspondingly connected to the vibrating lifting device 6 .

[0022] In this embodiment, the vibration lifting device 6 can adopt figure 2 with image 3 The structure shown in , its motion principle is similar to a Ferris wheel, can use the conveyor belt to transport multiple raw material trays 4, and the vibration lifting device 6 includes a conveying device 6-1, a raw material tray support 6-2, and a raw material tray hanging shaft 6 -3 and raw material tray connector 6-4, the function of the transmission device 6-1 is the same as the transmission principle of the center big wheel of the Ferris wheel, and the raw material tray support 6-2 with the same number of raw material trays is distributed on the transmission device 6-1 , fixed on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com