Squeezing juicer convenient to assemble and disassemble

A juicer technology that is easy to disassemble and assemble. It is applied in the field of food processing, which can solve the problems of reducing user enthusiasm for use, increasing replacement costs, and low effective use rate, so as to improve user satisfaction, reduce use noise, and space utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

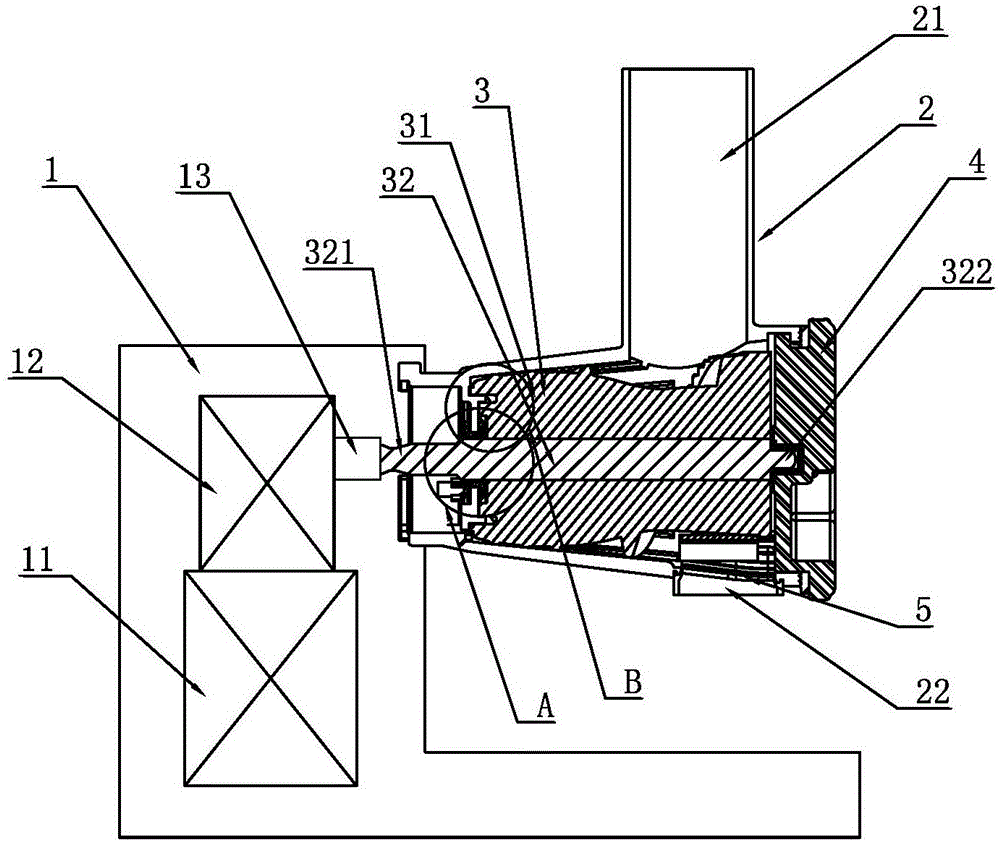

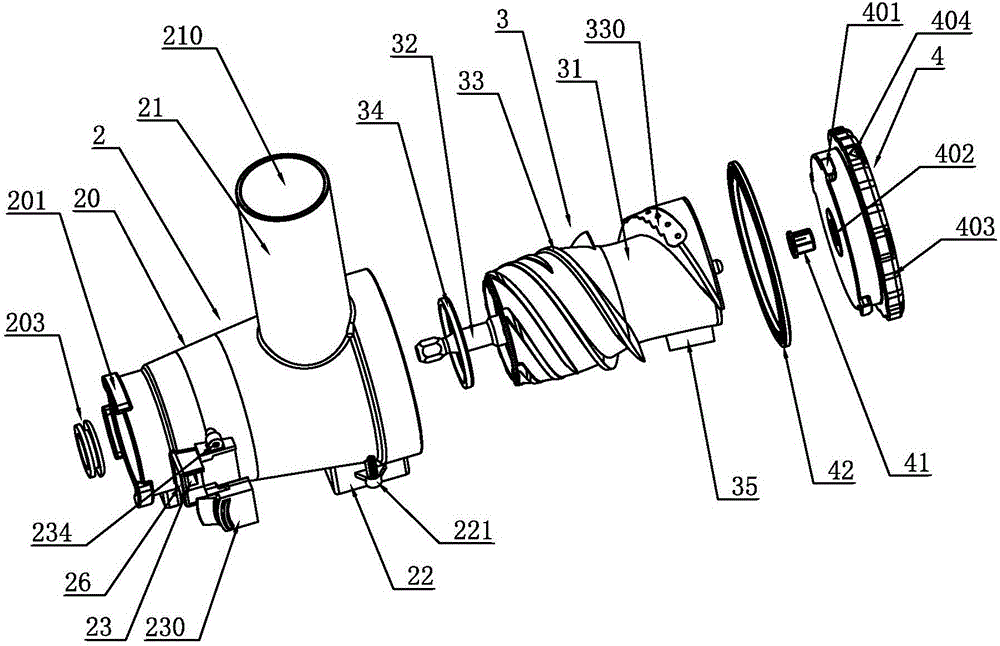

[0073] As the first embodiment of the easy-to-assemble squeeze juice extractor of the present invention, as figure 1 , 2 , 3, and 4, the juice extractor includes a base 1 and processing components. The machine base 1 is provided with a motor 11 and a reduction box 12 connected with the motor power, and the reduction box 12 has an output shaft 13 . Of course, the machine base 1 is also provided with a switch button for controlling the juice extractor. Correspondingly, the machine base 1 is also provided with a control unit for controlling the juice extractor. Preferably, the control unit It can control the forward rotation and reverse rotation of the motor, wherein the juice extractor rotates forward when it is working normally, and in the abnormal working process, the control unit will control the motor to reverse and drive the screw to reverse. The purpose of this setting is that if the juicer The machine is blocked by materials during the working process and cannot process...

Embodiment 2

[0096] As the second embodiment of the convenient disassembly and assembly of the squeeze juicer according to the present invention, such as Figure 16 As shown, the difference from the first embodiment is that the head end of the extraction cartridge is connected to the base.

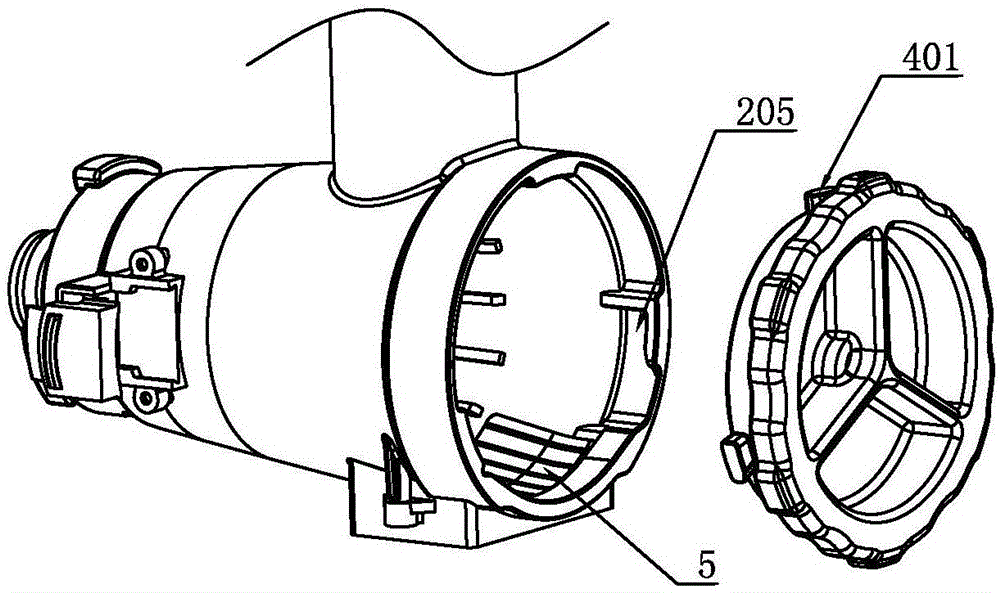

[0097] like Figure 16 , 17 , 18 , 19 , the processing assembly includes an extraction cylinder 2 , a screw 3 and a filter part 5 . The head end of the extraction cylinder 2 is provided with an opening 200 , the opening is provided with a fixing cover 4 , the outer side of the fixing cover 4 is provided with a fixing buckle 405 , and the fixing buckle 405 of the fixing cover 4 is connected to the fixed cover 4 . The base 1 is connected, and the extraction cartridge 2 is further connected to the base 1 through the fixing cover 4 . A sealing ring 42 is also provided between the fixed cover 4 and the extraction cylinder 2 .

[0098] The extraction cylinder 2 includes a cylinder body 20 and a feeding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com