Easy-cleaning extrusion type juice extractor

A juicer and extrusion technology, which is applied in the field of low-speed screw extrusion type juicer, can solve the problems of reducing user enthusiasm, cumbersome operation, and increasing cleaning time, so as to improve user satisfaction and high structural strength , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

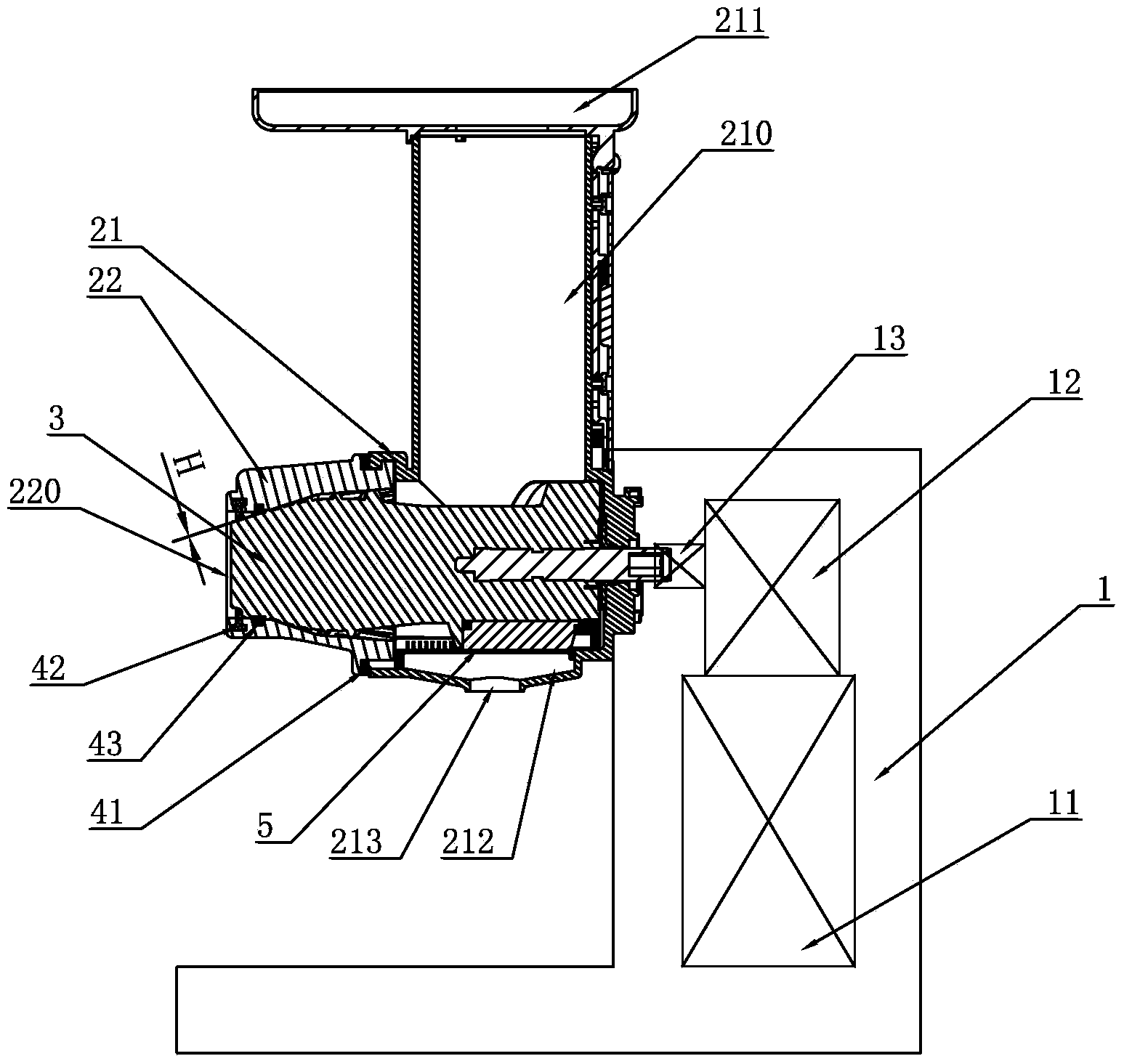

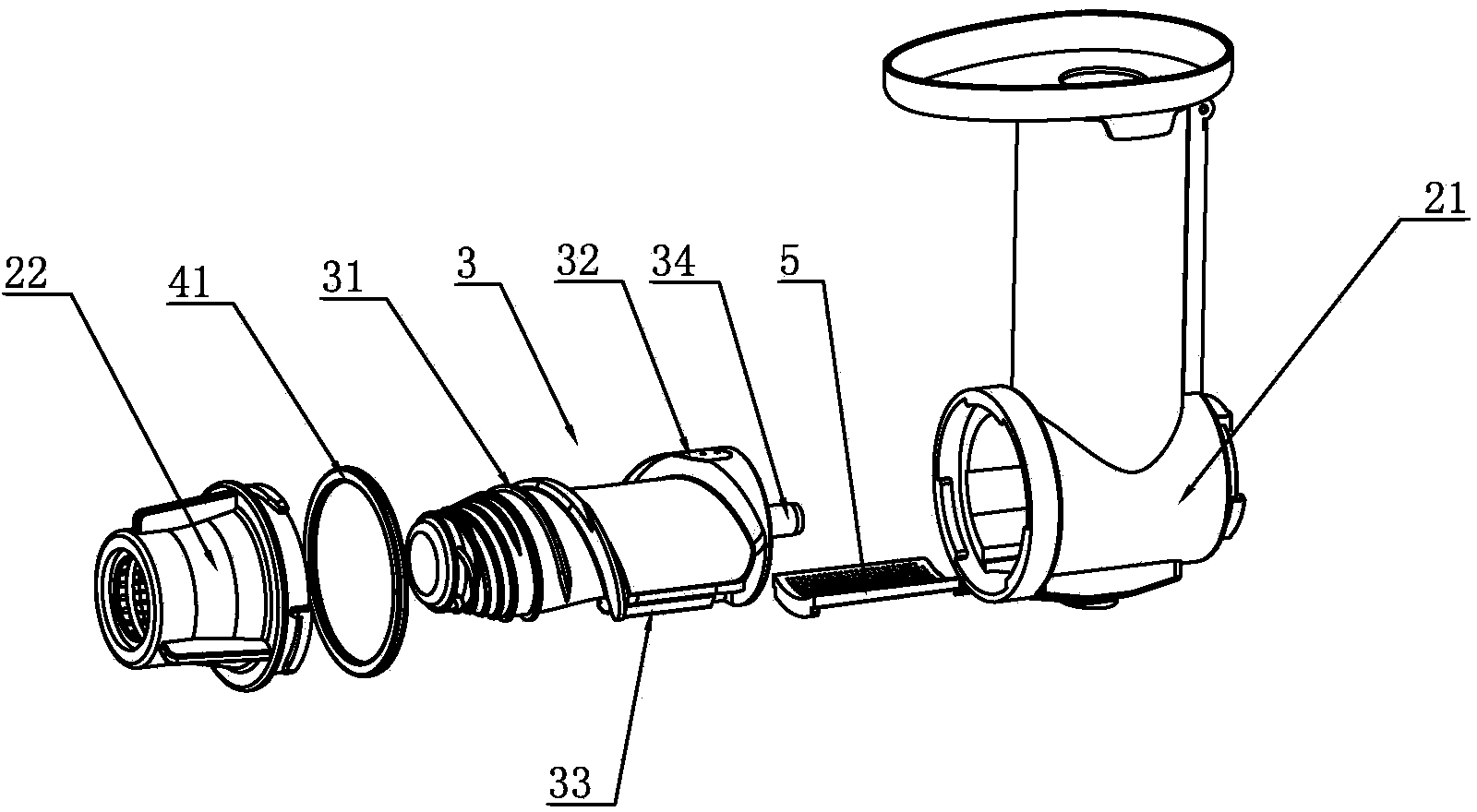

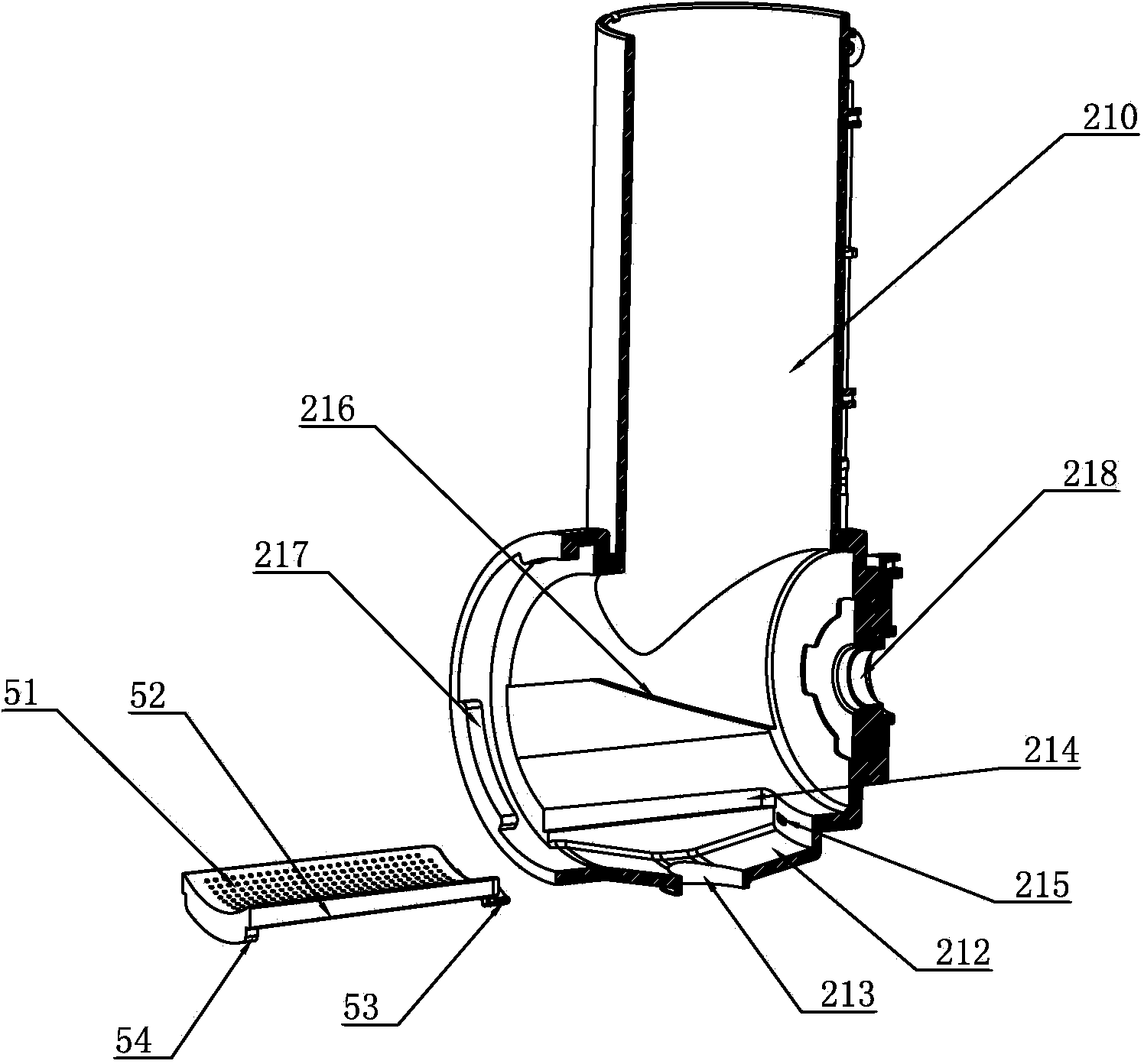

[0047] As the first embodiment of the easy-to-clean squeezing juice extractor of the present invention, as figure 1 Said, the juice extractor includes a base 1 and processing components, the base 1 is provided with a motor 11, the motor 11 is provided with a reduction box 12, and the reduction box 12 is provided with a drive shaft 13, the The drive shaft 13 is used to power the machining assembly. The processing assembly includes a juice collecting chamber 2, a screw 3 and a filter screen 5. The juice collecting chamber 2 is connected with the base 1, the screw 3 is arranged in the juice collecting chamber 2, and the screw 3 is connected with the driving shaft 13 by power. Preferably, the juice collection chamber 2 is rotationally engaged with the base 1, that is, the base is provided with a fixing groove, and the juice collection chamber 2 is provided with a matching rib, and the rib Insert into the fixing slot and rotate at a certain angle to fix the juice collecting chamb...

Embodiment 2

[0072] As the second embodiment of the easy-to-clean squeezing juice extractor of the present invention, as Figure 12 As shown, the difference from the first embodiment is that the filter is arranged on the extrusion part.

[0073] Such as Figure 12 As shown, the filter 5 is integrated with the extruding part 22 , the filter 5 is arranged at the front end of the extruding part 22 , and the juice extractor also includes a fixing buckle 6 .

[0074] Such as Figure 12 , 13 As shown, the filter net 5 is inserted into the accommodating portion 21 and blocks the juice outlet 213 . The outer edge of the rear end of the receiving part 21 is provided with a fixing rib 219, the inner side of the fixing buckle 6 is provided with a card slot 61, and the outer surface of the fixing buckle 6 is also provided with a toggle 62, and the fixing buckle 6 can be wound around the The juice collecting chamber 2 rotates axially, and the fixing rib 219 slides into the slot 61 to fix the receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com