Pressurizing/depressurizing dual-purpose operating console type chromatographic column

A chromatographic column and operating platform technology, which is applied in the field of dual-purpose operating desktop chromatographic column for pressure and pressure reduction, can solve the problems affecting the separation effect, uneven stationary phase, etc., and achieve the effects of simple operation, improved success rate, and guaranteed bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

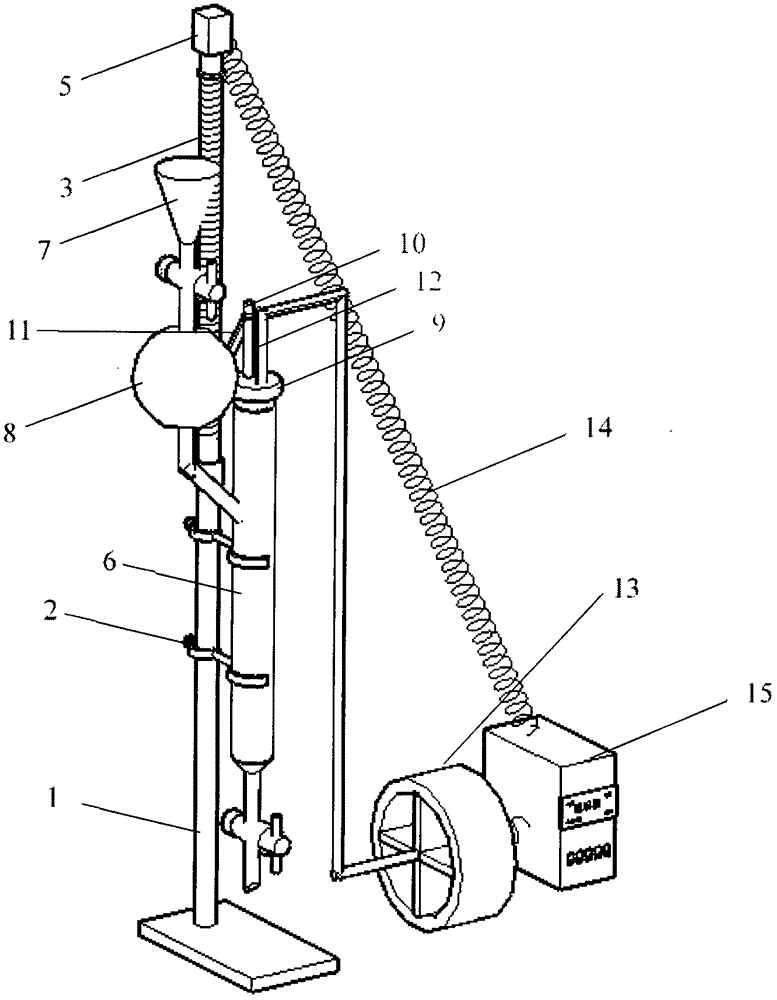

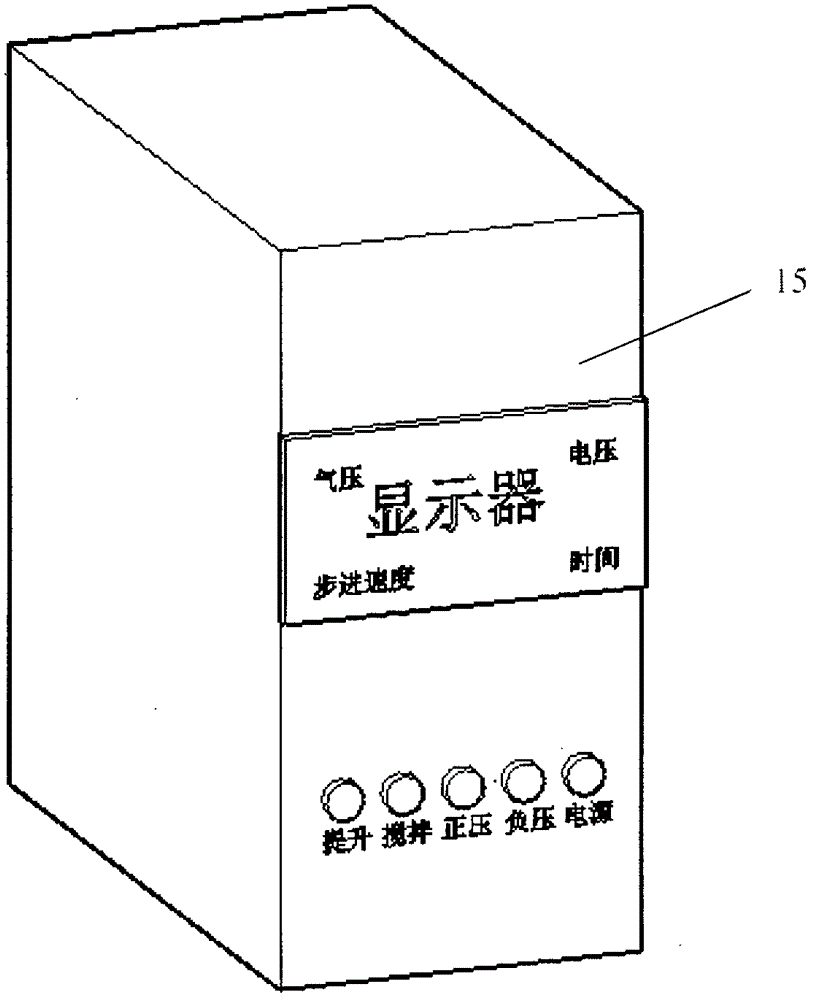

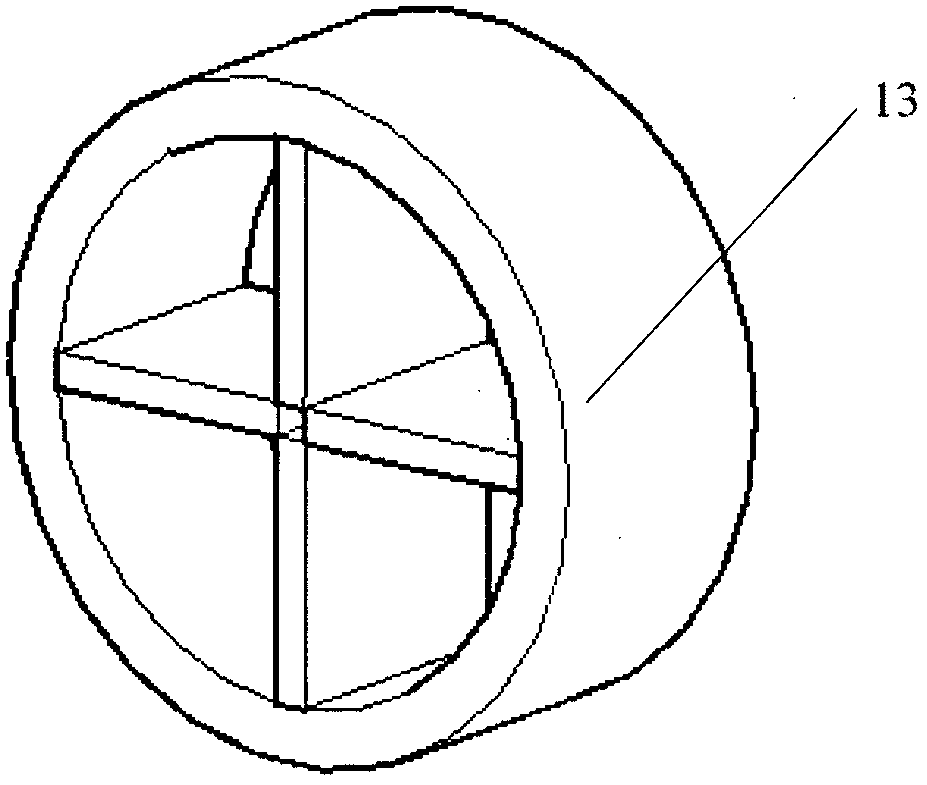

[0025] A desktop chromatographic column with dual-purpose operation for increasing and decompressing, including an experimental support 1, a test tube clamp 2, a lead screw 3, a nut 4, a stepping motor 5, a chromatographic column 6, a liquid inlet funnel 7, a liquid storage ball 8, a double Hole ground column cover 9, ring stirring rod 10, connecting rod 11, air inlet and outlet pipeline 12, dual-purpose vacuum pump 13 for positive and negative pressure, connecting wire 14, and console 15.

[0026] like figure 1 As shown, the experimental bracket 1 in the chromatography column is placed on the experimental table, with a test tube clamp 2 on it, and its upper end is connected with the lead screw 3; the lead screw 3 is covered with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com