High-efficiency glycerol decolorization control appliance

A control equipment and high-efficiency technology, applied in separation methods, solid adsorbent liquid separation, organic chemistry, etc., can solve the problems of non-detachable decolorization device, incomplete decolorization of glycerin, unfavorable replacement of activated carbon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

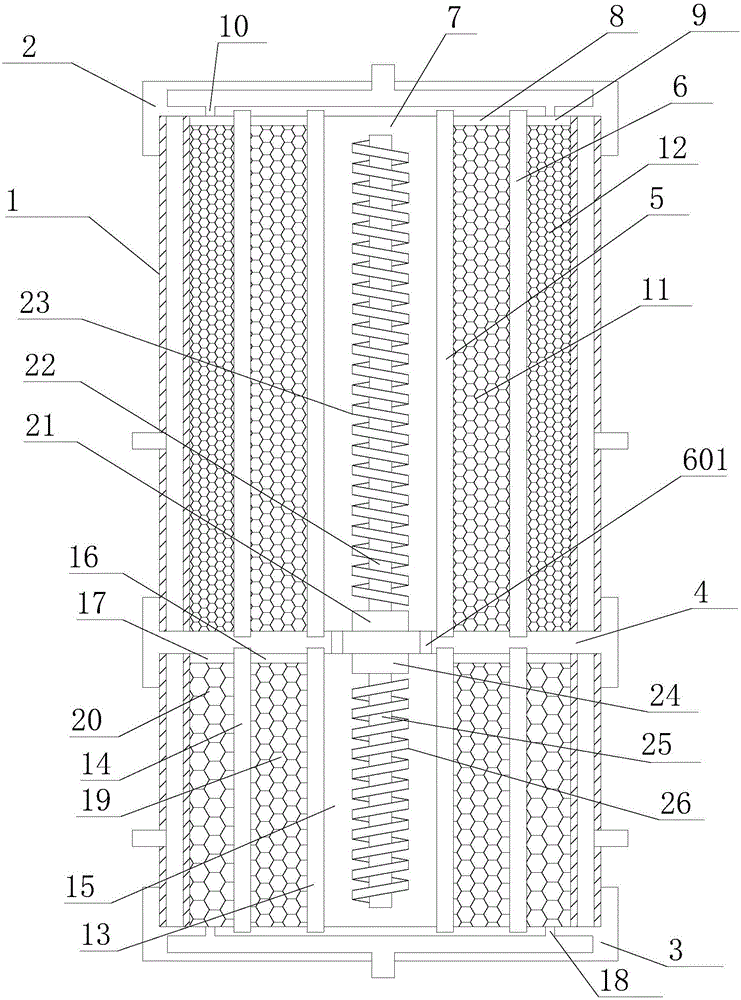

[0015] refer to figure 1 , the present invention proposes a high-efficiency glycerin decolorization control device, including a decolorization cylinder 1, a first cylinder cover 2, a second cylinder cover 3, a timer and a controller, wherein:

[0016] A partition 4 is arranged inside the decolorizing cylinder 1, and the partition 4 divides the inside of the decolorizing cylinder 1 into a first chamber and a second chamber. The first cylinder cover 2 is detachably mounted on the upper end of the first chamber to seal the first chamber, specifically: the outer circumference of the end of the decolorization cylinder 1 near the first cylinder cover 2 is provided with a first external thread, and the inner side of the first cylinder cover 2 is provided with There is a first internal thread that cooperates with the first external thread, and the decolorization cylinder 1 is threadedly connected with the first external thread and the first internal thread of the first cylinder cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com